A kind of tantalum nitride photoanode mediated by lanthanum chloride molten salt and preparation method thereof

A photoanode, molten salt technology, applied in electrodes, manufacturing tools, heat treatment equipment, etc., can solve the problem of no breakthrough progress, and achieve the effect of inhibiting recombination, high crystal quality and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] LaCl 3 molten salt mediated Ta 3 N 5 Photoanode preparation.

[0024] 1) Pre-oxidation: first cut the Ta foil into a size of 12 mm × 10 mm, then ultrasonically clean the Ta foil in acetone, ethanol and deionized water, and then anneal at 500 ° C in air for 1 h to form a layer of gray oxidation. layer.

[0025] 2) LaCl 3 Addition of molten salt: Place the oxidized Ta foil in step 1) on the heating plate, then add 0.5M LaCl dropwise with a pipette on the Ta foil 3 Solution 100uL. When the solvent evaporates, a dense, smooth, translucent layer of LaCl is formed. 3 film.

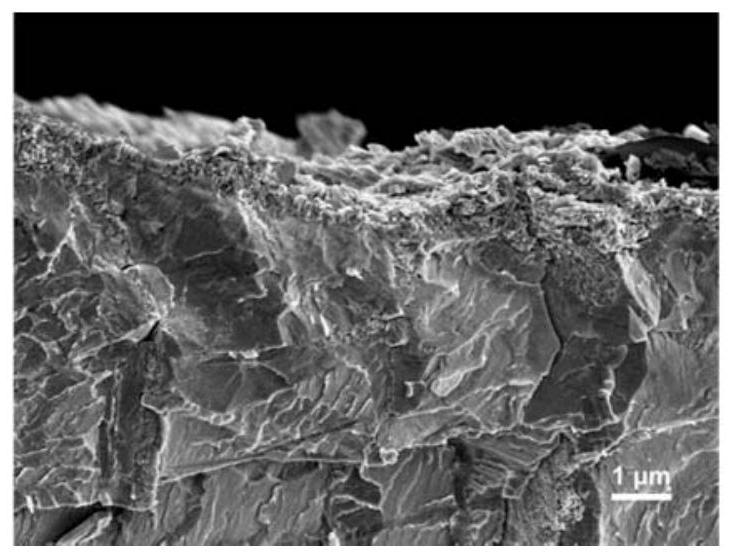

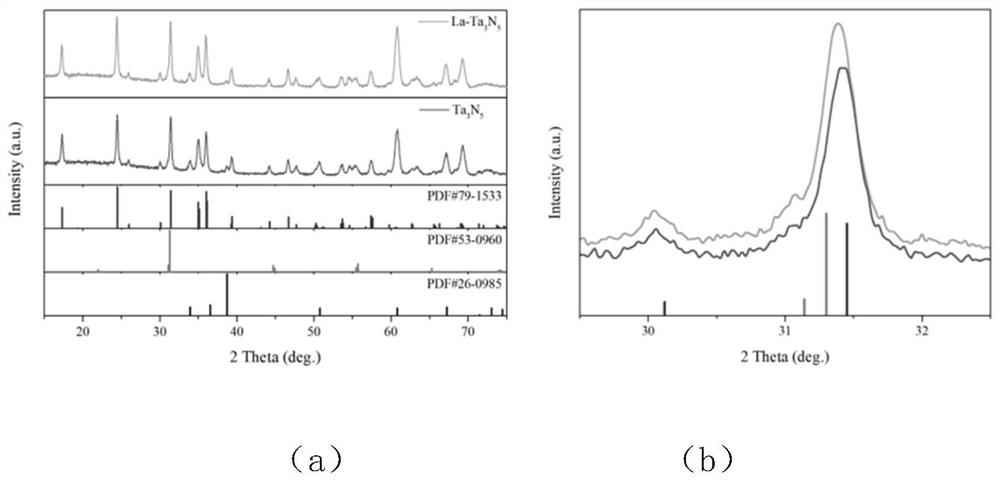

[0026] 3) LaCl 3 molten salt mediated Ta 3 N 5 Preparation of photoanode: heat-treat the precursor in step 2) in an ammonia atmosphere, and keep it at 900°C for 5h to obtain LaCl 3 molten salt mediated Ta 3 N 5 Photoanode, named La-Ta 3 N 5 . The LaCl 3 molten salt mediated Ta 3 N 5 The shape of the photoanode is as figure 1 As shown, the electrode sheet appears as a red light absorber...

Embodiment 2

[0029] LaCl 3 molten salt mediated Ta 3 N 5 Photoanode performance test.

[0030] 1) LaCl obtained in Example 1 3 molten salt mediated Ta 3 N 5 Photoanode, with cobalt oxide (Co 3 o 4 ) is the cocatalyst to Ta 3 N 5 Flat photoanodes were optimized by a modified hydrothermal method at Ta 3 N 5 Hydrothermal deposition of Co on 3 o 4 nanoparticles.

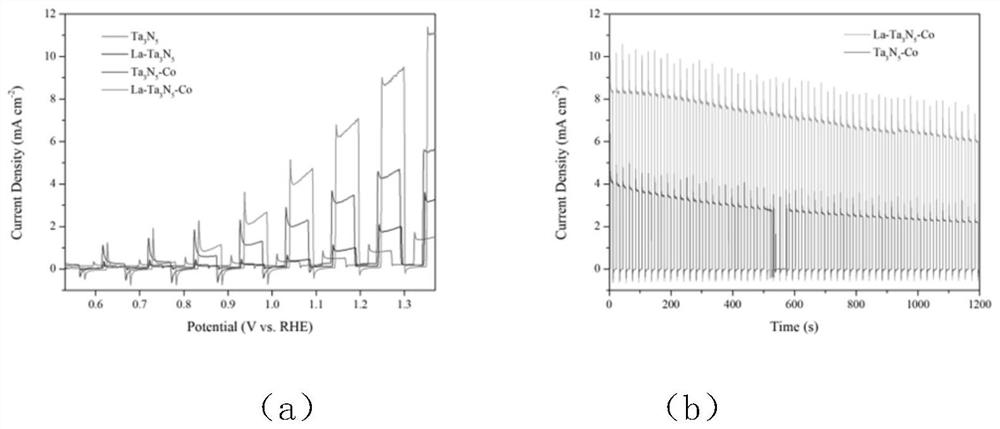

[0031] 2) Photoelectrocatalytic performance test: We used a standard three-electrode system to perform chronoamperometry at a potential of 1.23V vs. RHE under AM 1.5G illumination (1 standard sunlight). Test La-Ta 3 N 5 Photoelectrocatalytic water splitting performance in 1M NaOH solution (supported cocatalyst Co 3 o 4 named La-Ta 3 N 5 -Co). Such as image 3 shown in LaCl 3 With the help of molten salt, La-Ta 3 N 5 The photocurrent reaches 1.7mA cm -2 . In addition, at load Co 3 o 4 After cocatalyst, La-Ta 3 N 5 -Co photoanode reaches 8.2mAcm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com