Construction method for existing basement pile foundation with high water level

A basement, high water level technology, applied in the direction of foundation structure engineering, sheet pile walls, building maintenance, etc., can solve the problems of the damage of the built structure, the difficulty of controlling the verticality of the pile, and the narrow construction space, so as to reduce energy consumption and protect Groundwater resources and the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

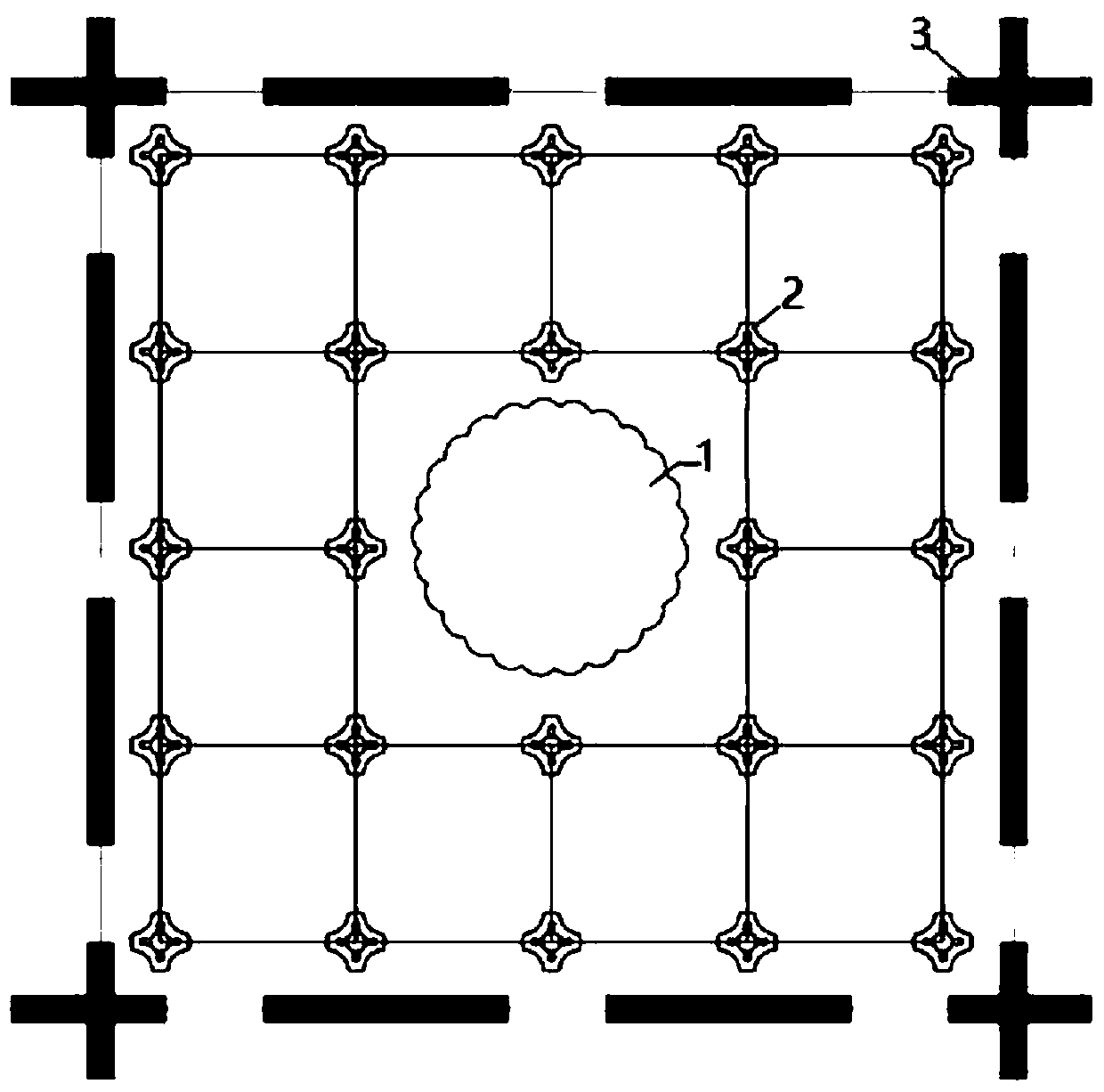

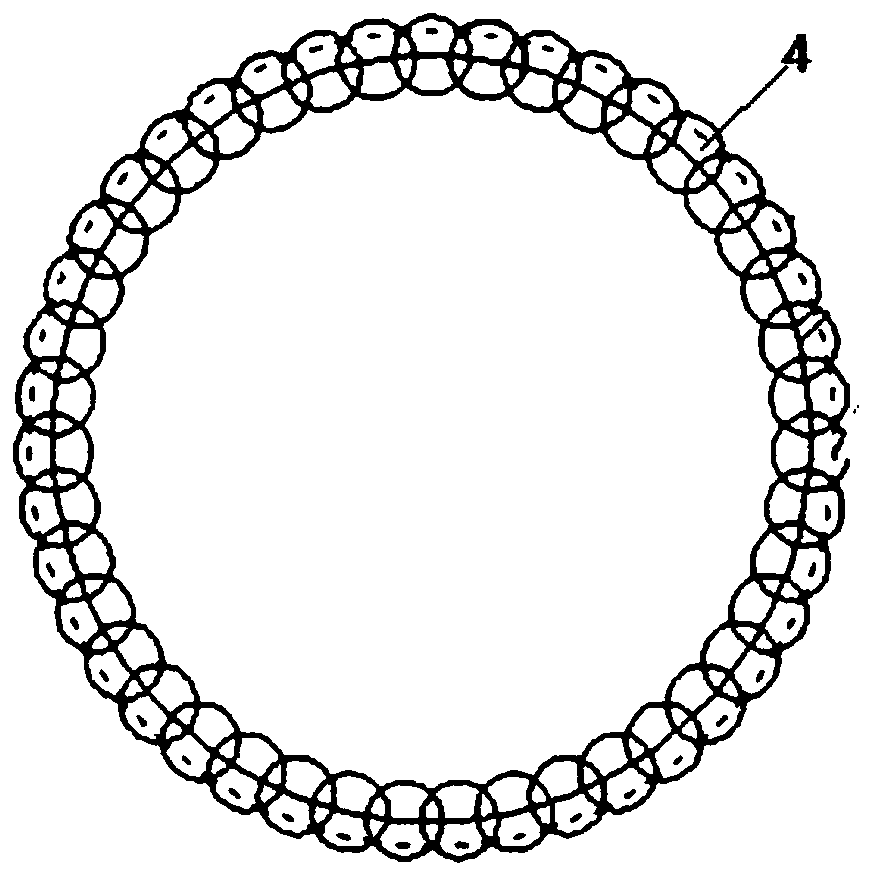

[0034] The first aspect of the present invention discloses a pile foundation construction method for an existing basement with a high water level, which includes the following steps in sequence: pre-construction preparation step, floor reinforcement step, hole opening step, sleeve placement step, pile forming construction step and recovery sleeve cylinder step.

[0035] Specifically, the plan is as follows:

[0036] 1. Construction preparation

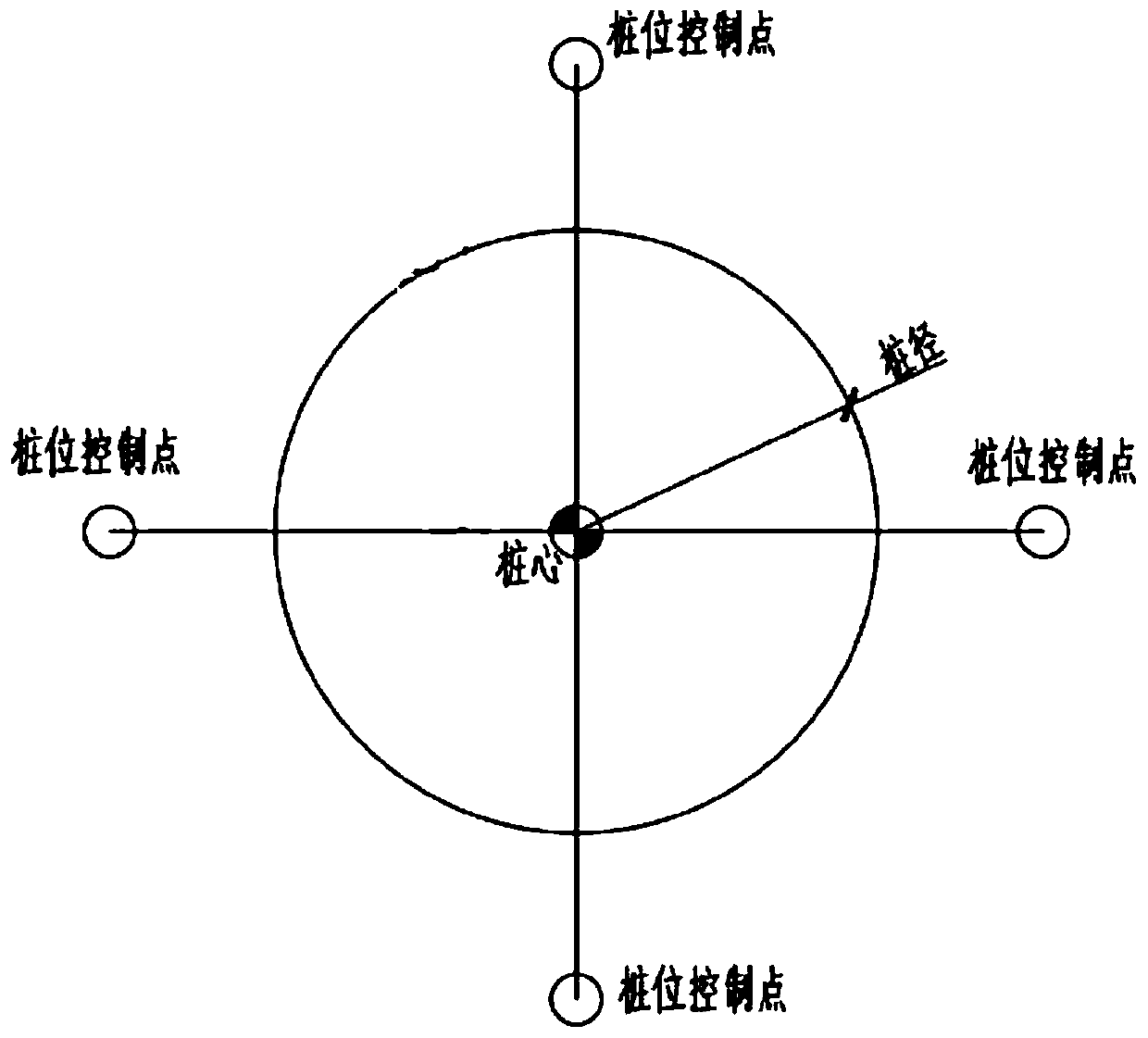

[0037] 1. Pile position review

[0038] After receiving the design unit's supplementary pile positioning drawing, organize relevant technical personnel to review the pile positioning drawing and the original structural drawing to check whether there are main force-bearing components such as the main beam, column, wall, etc. of the pile foundation positioning and the original structure In case of a collision. In view of this situation, communicate with the design, and fine-tune the pile positioning within the allowable range, reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com