Electrostatic monitoring system and electrostatic monitoring method for liquefied hydrocarbon vehicle-loading area

A monitoring system and a technology for liquefying hydrocarbons, which are applied in the methods of container discharge, container filling methods, and equipment loaded into pressure vessels, etc., can solve problems such as anti-static shoes and clothing that do not meet safety standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

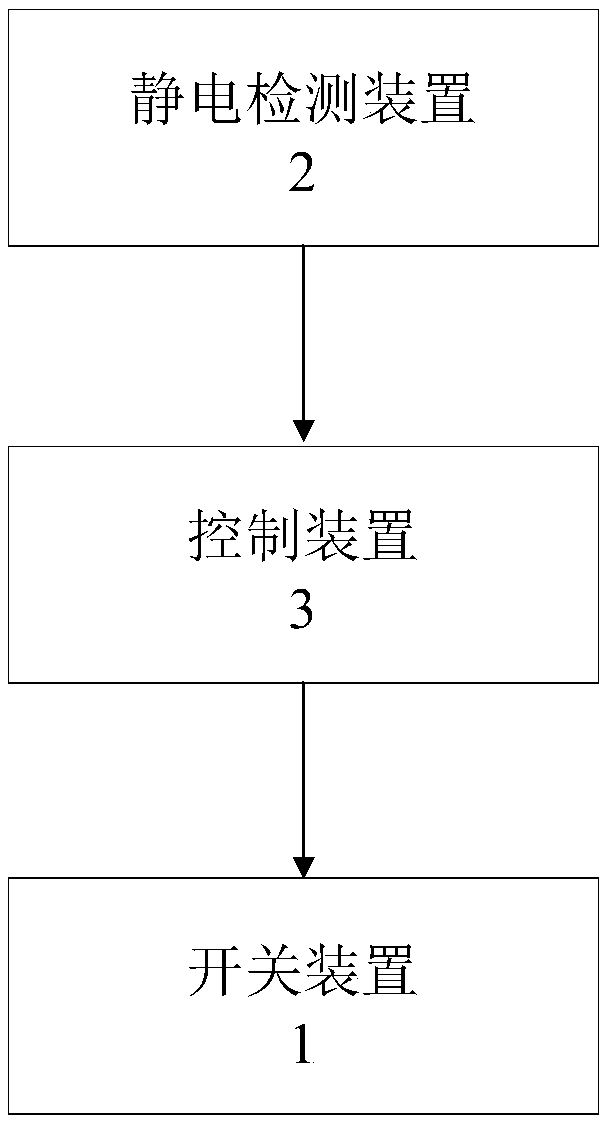

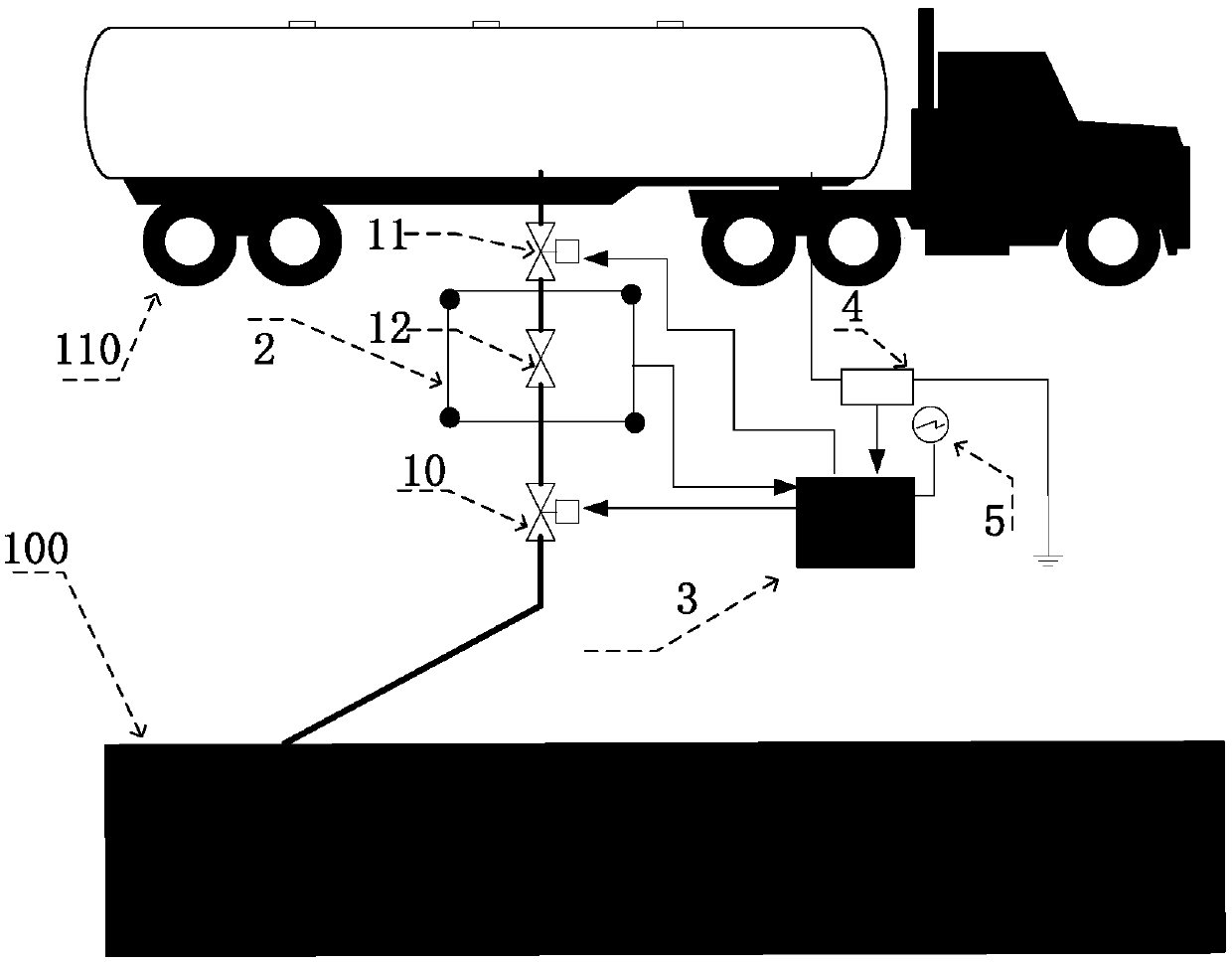

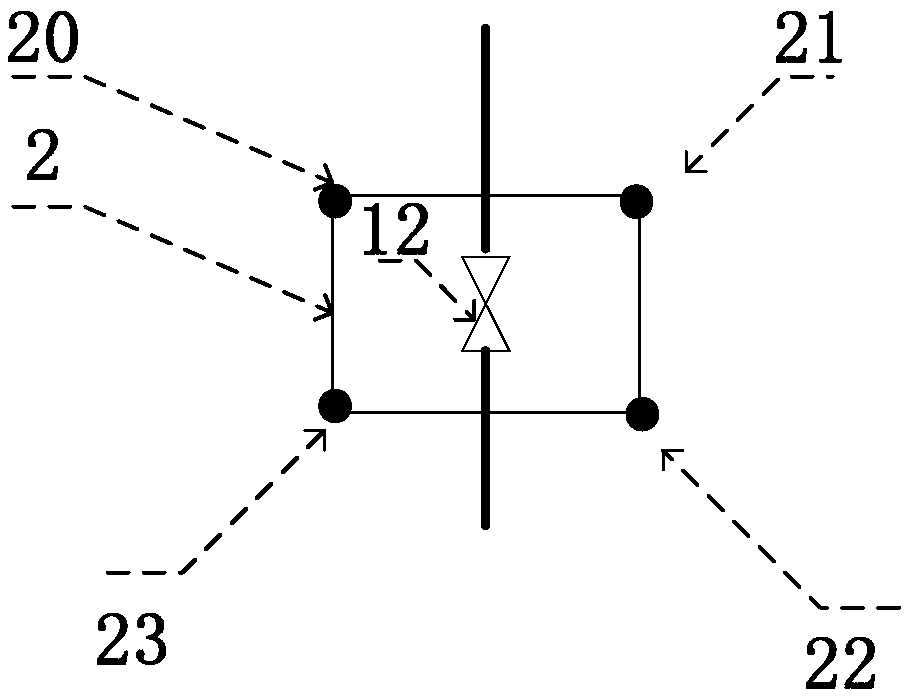

[0030] figure 1 It is a structural diagram of an electrostatic monitoring system used in a liquefied hydrocarbon loading area provided by an embodiment of the present invention. Such as figure 1 As shown, the electrostatic monitoring system for the liquefied hydrocarbon loading area provided by the present invention may include: a switch device 1, which is installed between the tank car entrance and the tail end of the loading arm for guiding Pass or cut off the pipeline between the inlet of the tank car end and the tail end of the loading arm to start or stop the loading operation of the liquefied hydrocarbon; the static monitoring device 2 is used to monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com