Multi-mode frictional wear test device and method

A friction and wear test, multi-mode technology, applied in the direction of measuring devices, using mechanical devices, testing wear resistance, etc., can solve the problems of functional limitations, impossibility of impact-sliding-rolling composite friction and wear tests, complex structure, etc., to achieve The effect of simple structure and saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features or steps.

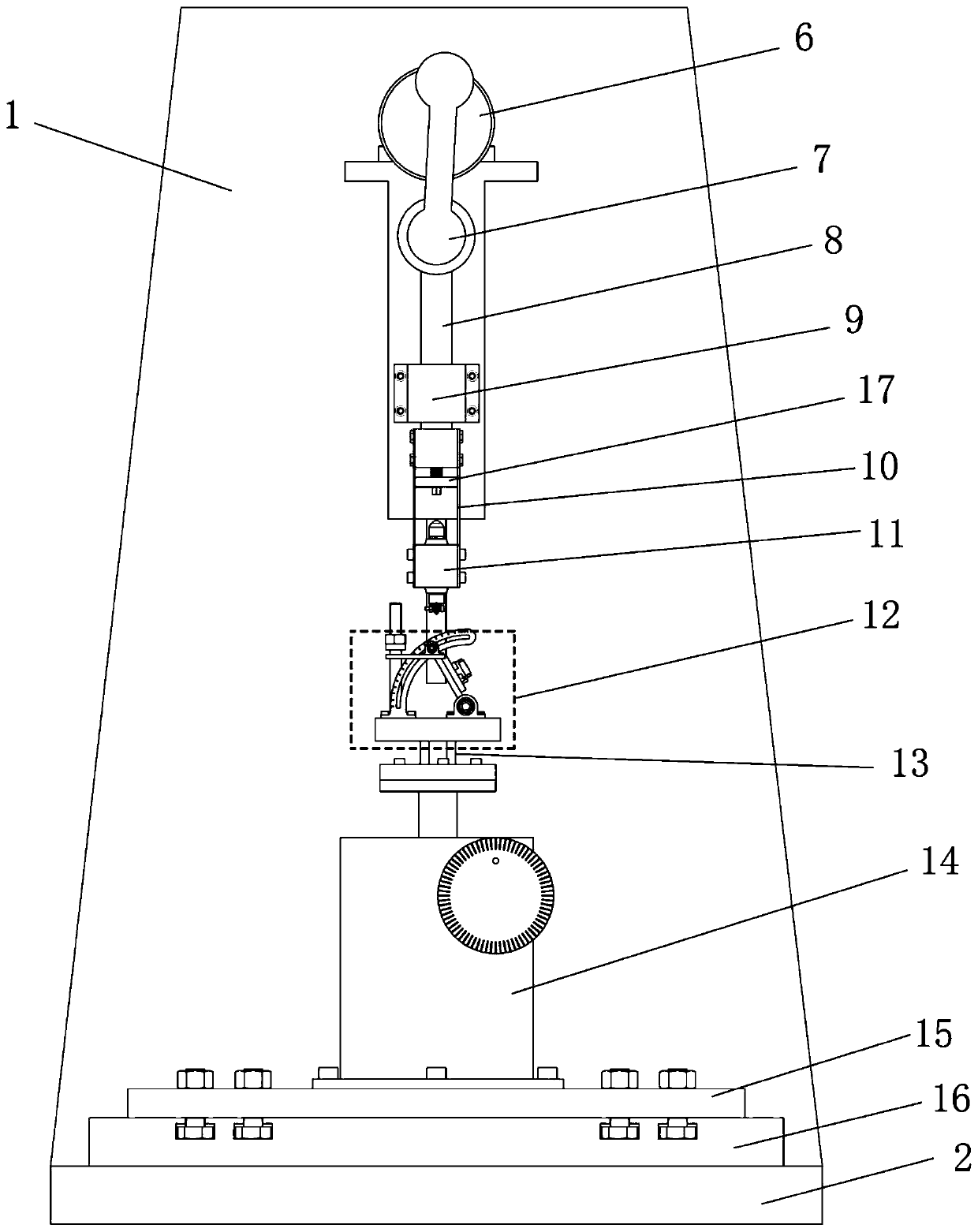

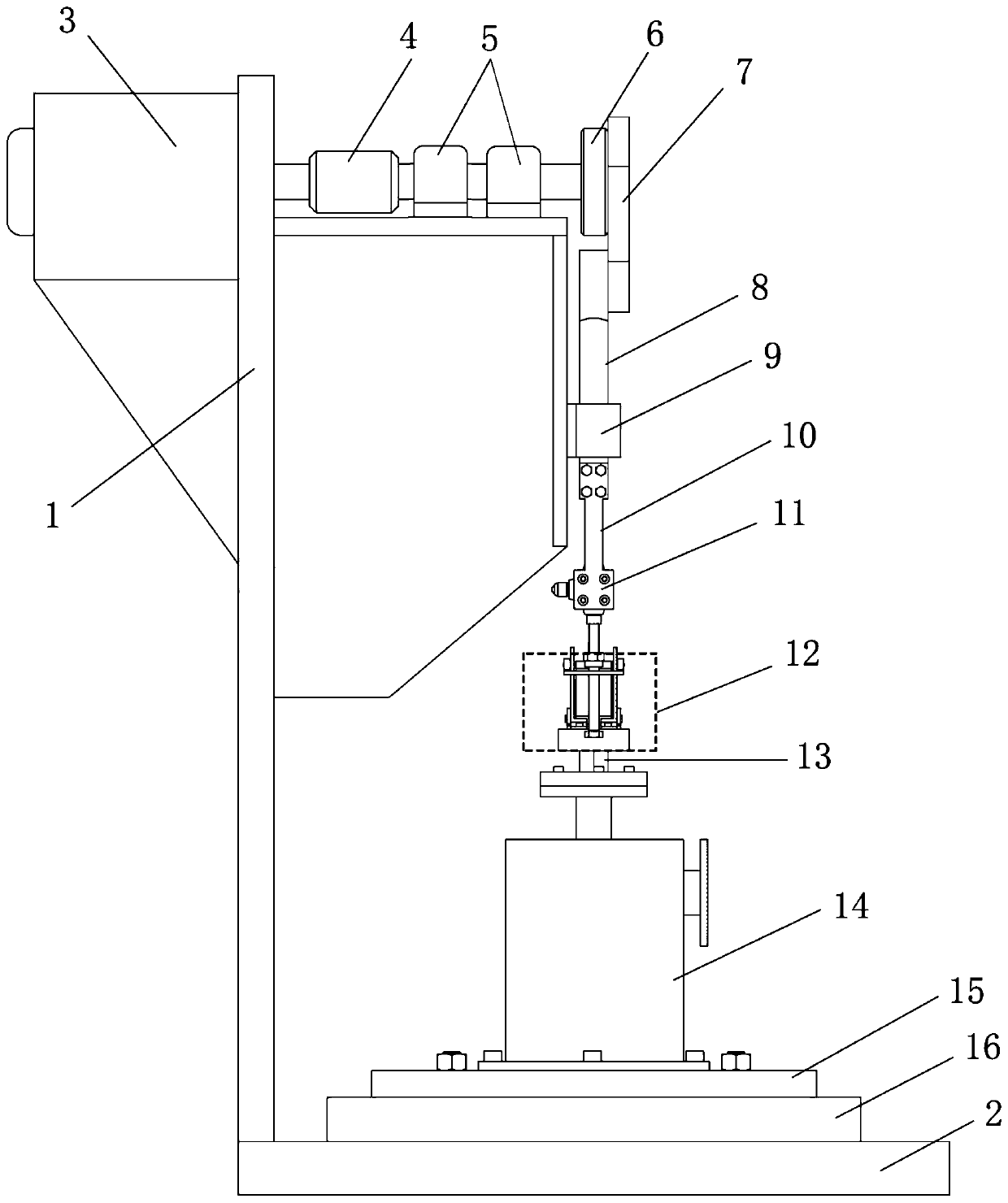

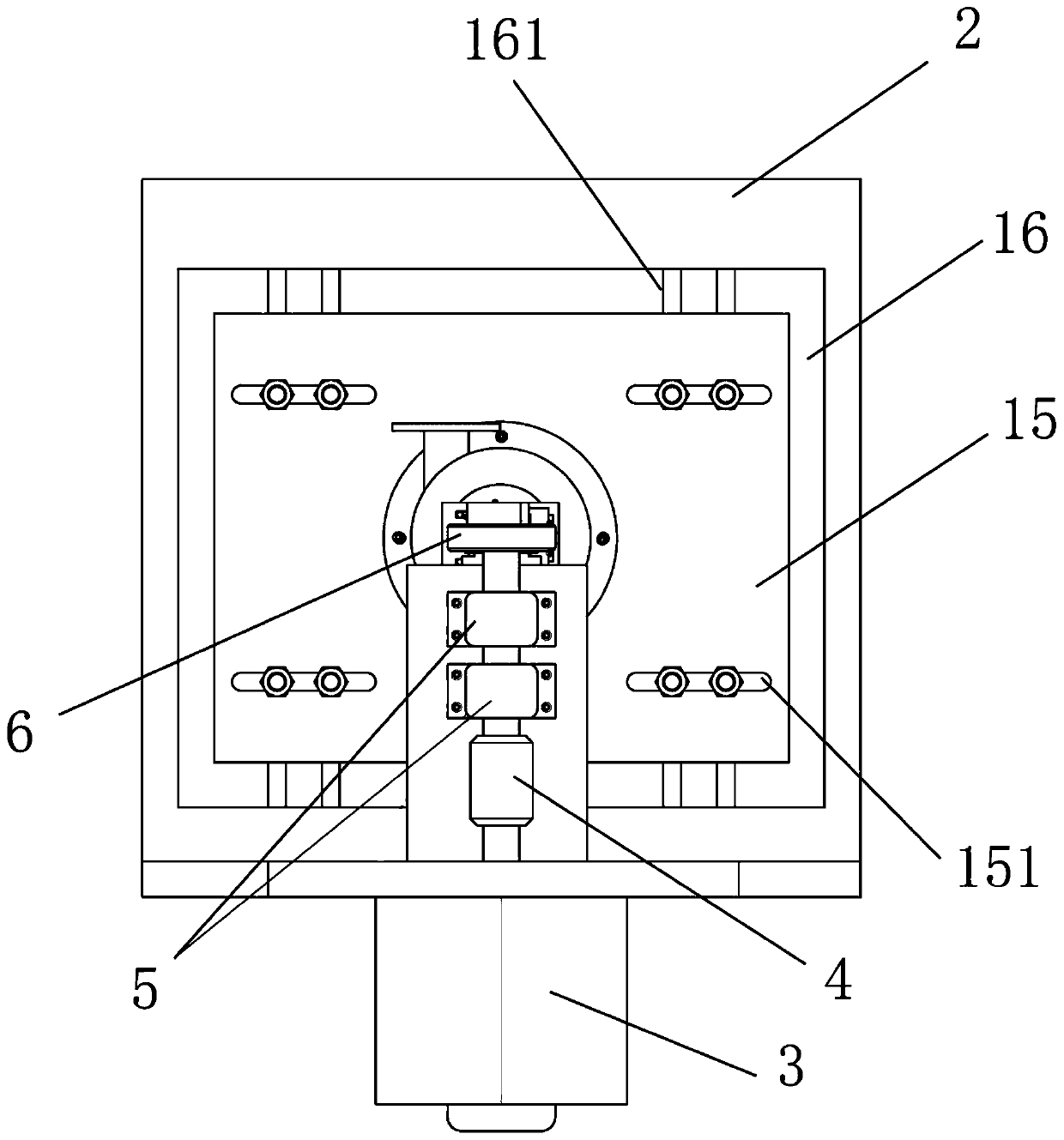

[0056] Combine below Figure 1 to Figure 10 The present invention will be described in detail.

[0057] A multi-mode friction and wear test device includes a frame 1 and a base 2, the upper part of the frame 1 is provided with a driving device and a transmission device, and in this embodiment, the driving device is a motor 3. The transmission device is connected with a spring piece 10 , the spring piece 10 is connected with a spring stiffness adjuster 17 , and the lower end of the spring piece 10 is connected with a clamp connector 11 . The clamp connector 11 is connected with a spherical sample holder 111 or a rolling sample holder 112, the rolling sample holder 112 is connected with a rolling sample 114, and the two sides of the rolling sample 114 are respectively provided with four The increment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com