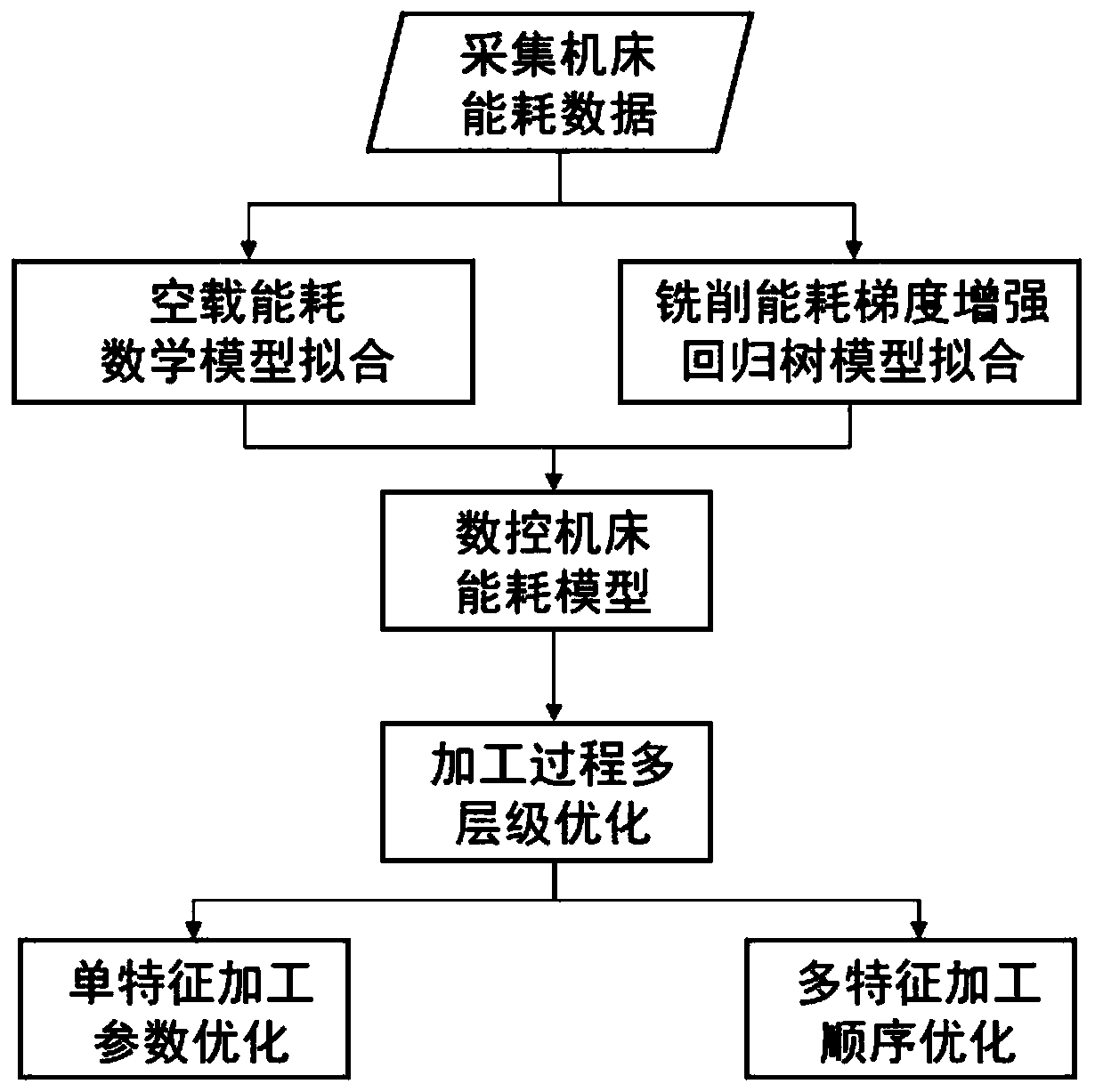

Numerical control machine tool energy consumption modeling and machining process optimization method

A technology of CNC machine tools and processing processes, applied in simulators, program control, computer control, etc., can solve problems such as lack of energy consumption models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

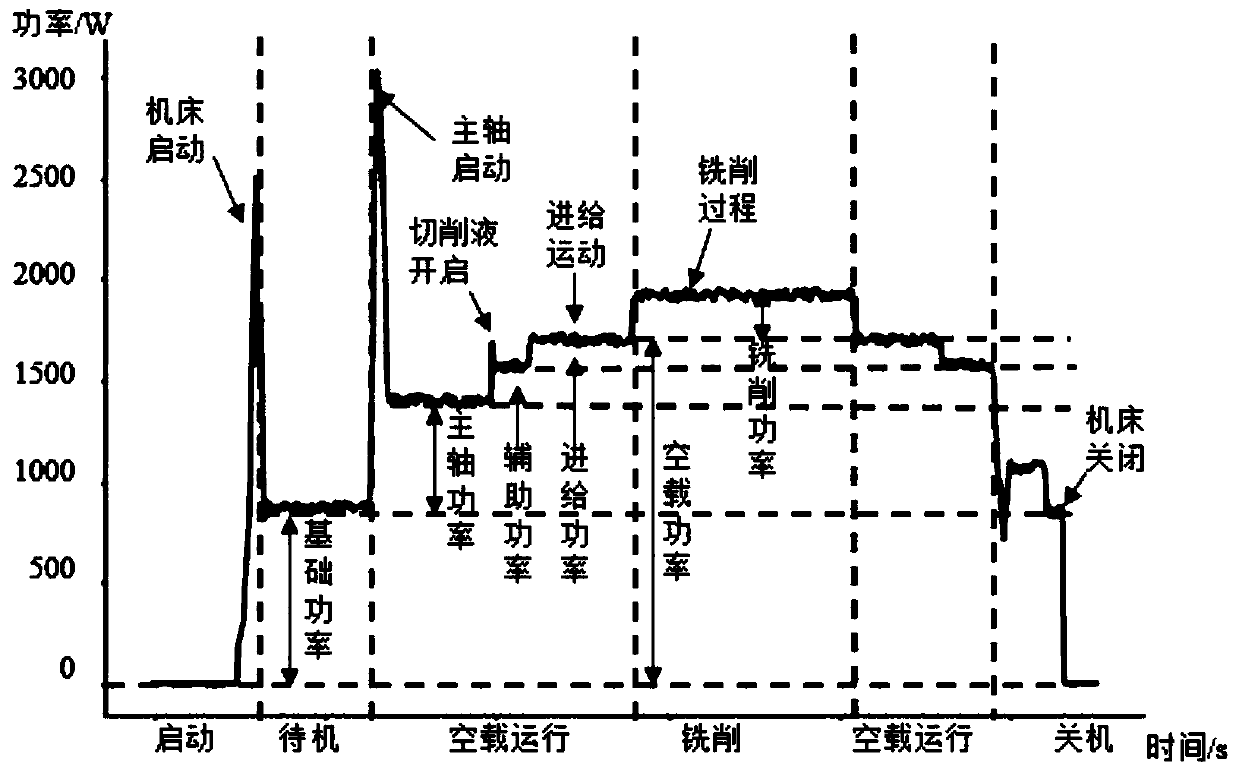

[0085] Step 1. Through the energy consumption modeling experiment, collect the energy consumption data under no-load conditions and during milling processing, and use outlier elimination and mean filtering to denoise the collected data. The energy consumption data can be connected to the power Obtained by the measuring equipment, the measured power curve is as figure 2 shown;

[0086] Step 2, use the energy consumption data in the non-processing state to fit the no-load energy consumption model of the machine tool, that is, establish the energy consumption model of the spindle, feed axis, and auxiliary functional components, and measure the basic energy consumption of the machine tool.

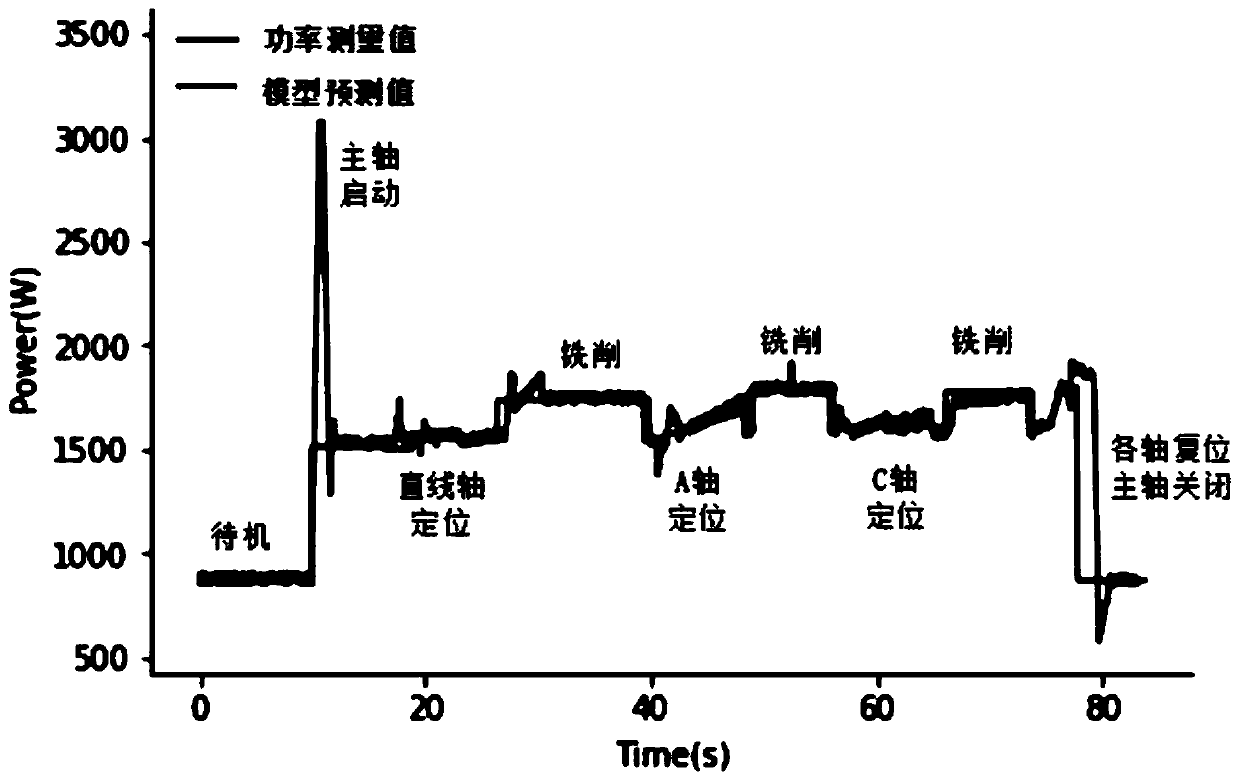

[0087] Step 3, constructing a milling model based on a gradient enhanced regression tree;

[0088] Step 4, by superimposing the no-load power and milling power models under the corresponding process parameters to obtain the real-time power of the machine tool, the model prediction effect is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com