Coagulant for water-based ink wastewater, and water-based ink wastewater treatment method

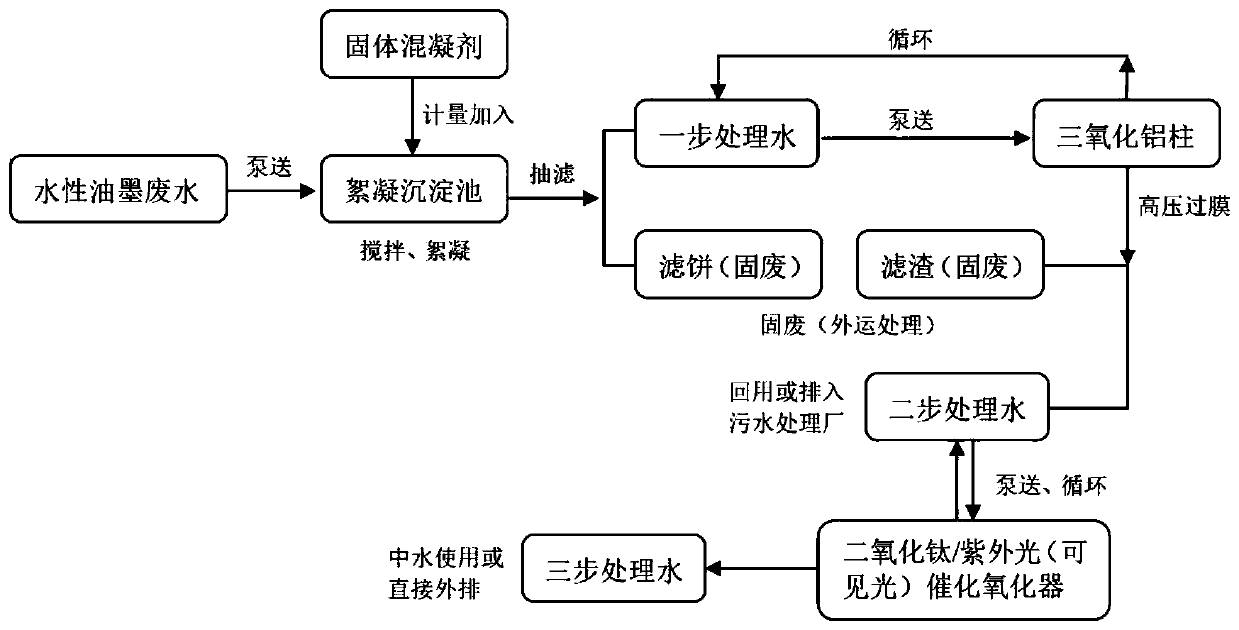

A technology for water-based ink and wastewater treatment, applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc. , free combination, the effect of light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

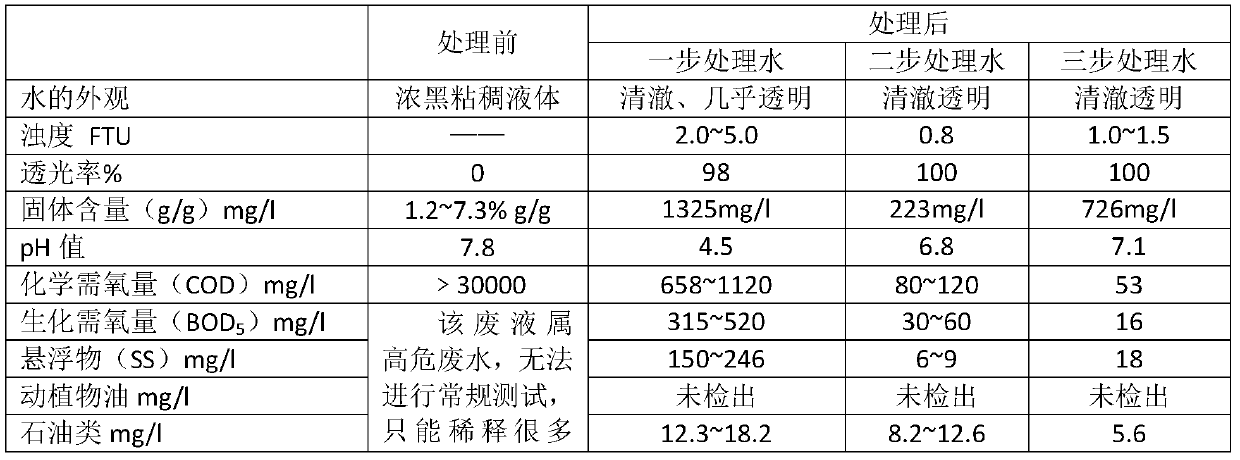

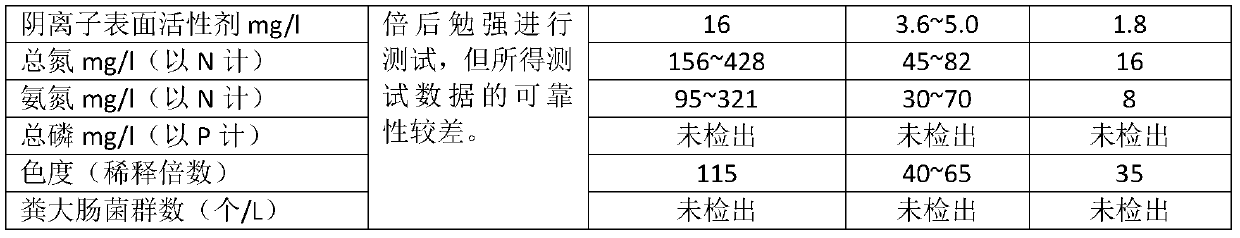

Examples

Embodiment 1

[0049] The coagulant used for water-based ink wastewater of the present embodiment includes: 250 parts by weight of dilute sulfuric acid and 80 parts of powder; wherein: the volume concentration of the dilute sulfuric acid is 50%; Alumina, activated carbon and vermiculite powder, the mass ratio is 0.5:1:100.

Embodiment 2

[0051] The coagulant used for water-based ink waste water of the present embodiment comprises: 350 parts by weight of dilute sulfuric acid and 120 parts of powder; Wherein: the volume concentration of described dilute sulfuric acid is 60%; Described powder comprises: polymerization Alumina, activated carbon and vermiculite powder, the mass ratio is 2:5:100.

Embodiment 3

[0053] The coagulant used for water-based ink wastewater of the present embodiment includes: 280 parts by weight of dilute sulfuric acid and 90 parts of powder; wherein: the volume concentration of the dilute sulfuric acid is 55%; The mass ratio of alumina, activated carbon and vermiculite powder is 0.8:1.5:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com