Preparation and application methods of amino acid chelated selenium foliar fertilizer

A technology for chelating selenium and amino acids, applied in fertilization methods, applications, liquid fertilizers, etc., can solve the problems of high cost, instability, low utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

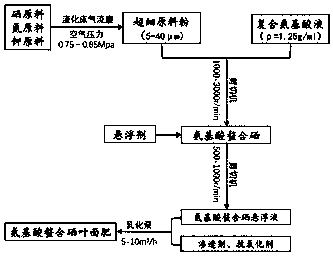

[0018] 20 parts of selenium raw material, 150 parts of nitrogen raw material, and 150 parts of potassium raw material are carried out ultra-fine processing by fluidized bed airflow pump according to the weight ratio to prepare raw material powder. The particle diameter of ultrafine raw material powder is 5 μm. The prepared ultra-fine raw material powder and the compound amino acid liquid are put into the reactor and mixed in a weight ratio of 1:1, and under the action of a high-speed shearing machine, fully shear and chelate to generate amino acid chelated selenium, and the rotating speed of the shearing machine is 1000r / min, the chelating time is 30min, and the chelating temperature is 45°C. Add 0.3 part of suspending agent to the prepared amino acid chelated selenium, and then carry out shear mixing to generate amino acid chelated selenium suspension, and the shear mixing time is 10 min. Add 0.1 part of penetrant and 0.1 part of antioxidant to the prepared amino acid chelat...

Embodiment 2

[0020] 80 parts of selenium raw material, 300 parts of nitrogen raw material, and 200 parts of potassium raw material are carried out ultra-fine processing by fluidized bed airflow pump according to the weight ratio, and raw material powder is prepared. The operating condition of fluidized bed airflow pump is 0.75-0.85Mpa, prepared The particle diameter of ultrafine raw material powder is 10 μm. The prepared ultra-fine raw material powder and the compound amino acid liquid are put into the reactor and mixed in a weight ratio of 1:1, and under the action of a high-speed shearing machine, fully shear and chelate to generate amino acid chelated selenium, and the rotating speed of the shearing machine is 2000r / min, the chelation time is 40min, and the chelation temperature is 55°C. Add 0.8 parts of suspending agent to the prepared amino acid chelated selenium, and then shear and mix to generate amino acid chelated selenium suspension, and the shear mixing time is 20 min. Add 0.8 ...

Embodiment 3

[0022] 120 parts of selenium raw material, 750 parts of nitrogen raw material, and 500 parts of potassium raw material are carried out ultra-fine processing by fluidized bed airflow pump according to weight ratio, and raw material powder is prepared. The working condition of fluidized bed airflow pump is 0.75-0.85Mpa, prepared The particle diameter of the superfine raw material powder is 40 μm. The superfine raw material powder prepared and the compound amino acid liquid are put into the reaction kettle by weight ratio 3:1 and mix, under the effect of high-speed shearing machine, fully shear and chelate, generate amino acid chelated selenium, the rotating speed of shearing machine is 3000r / min, the chelating time is 60min, and the chelating temperature is 75°C. The prepared amino acid chelated selenium was added with 1.5 parts of suspending agent and then sheared and mixed to generate amino acid chelated selenium suspension, and the sheared mixed time was 40 min. Add 2 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com