Ultrahigh moisture-permeable matte thermoplastic polyurethane composition and preparation method thereof

A thermoplastic polyurethane and composition technology, applied in the field of ultra-high moisture-permeable matte thermoplastic polyurethane composition and its preparation, can solve the problems of no hydrophilic group, inability to exercise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

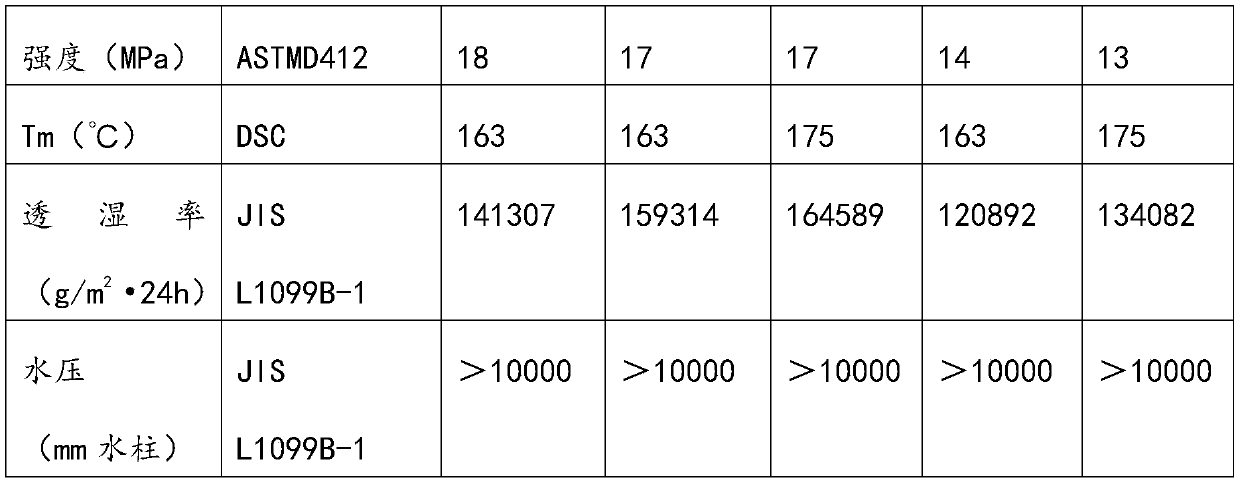

Embodiment 1

[0023] A preparation method of an ultra-high moisture-permeable matte thermoplastic polyurethane composition, the steps are as follows:

[0024] (1) Preparation of TPU

[0025] Take 169.5g of PEG2000, 29.2g of BDO and 101.3g of MDI, and use a twin-screw extruder to process and shape it at one time. The temperature in the reaction zone is 200°C. After the reaction, it is pelletized under water at 40°C;

[0026] (2) Preparation of moisture-permeable matte masterbatch

[0027] After drying TPEE and zeolite powder at 90°C for 5 hours, granulate through a twin-screw extruder at a processing temperature of 180°C to obtain a moisture-permeable matte masterbatch; the weight ratio of TPEE and zeolite powder is 75:25 ;

[0028] (3) Mix 300 g of thermoplastic polyurethane elastomer TPU in step (1) with 30 g of moisture-permeable matte masterbatch in step (2) to prepare an ultra-high moisture-permeable matte thermoplastic polyurethane composition.

Embodiment 2

[0030] A preparation method of an ultra-high moisture-permeable matte thermoplastic polyurethane composition, the steps are as follows:

[0031] (1) Preparation of TPU

[0032] Take 169.5g of PEG2000, 29.2g of BDO and 101.3g of MDI, and use a twin-screw extruder to process and shape it at one time. The temperature in the reaction zone is 200°C. After the reaction, it is pelletized under water at 40°C;

[0033] (2) Preparation of moisture-permeable matte masterbatch

[0034] After drying TPEE and zeolite powder at 90°C for 5 hours, granulate through a twin-screw extruder at a processing temperature of 180°C to obtain a moisture-permeable matte masterbatch; the weight ratio of TPEE and zeolite powder is 55:45 ;

[0035] (3) Mix 300 g of thermoplastic polyurethane elastomer TPU in step (1) with 30 g of moisture-permeable matte masterbatch in step (2) to prepare an ultra-high moisture-permeable matte thermoplastic polyurethane composition.

Embodiment 3

[0037] A preparation method of an ultra-high moisture-permeable matte thermoplastic polyurethane composition, the steps are as follows:

[0038] (1) Preparation of TPU

[0039] Take 174g of PEG2000, 101.5g of PDO and 24.5g of MDI, and use a twin-screw extruder to process and shape it at one time. The temperature in the reaction zone is 200°C. After the reaction, it is pelletized under water at 40°C;

[0040] (2) Preparation of moisture-permeable matte masterbatch

[0041] After drying TPEE and zeolite powder at 90°C for 5 hours, granulate through a twin-screw extruder at a processing temperature of 180°C to obtain a moisture-permeable matte masterbatch; the weight ratio of TPEE and zeolite powder is 75:25 ;

[0042] (3) Mix 300 g of thermoplastic polyurethane elastomer TPU in step (1) with 30 g of moisture-permeable matte masterbatch in step (2) to prepare an ultra-high moisture-permeable matte thermoplastic polyurethane composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com