Method for preparing high-purity isoparaffin from n-alkane

A technology for normal alkanes and isoparaffins, which is applied in the field of preparation of high-purity isoparaffins, can solve the problems of unknown components, complex process, chemical stability, coal-based Fischer-Tropsch synthesis technology is not as good as chemical synthesis technology, etc., to achieve economical Significant benefit, strong reaction processing ability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

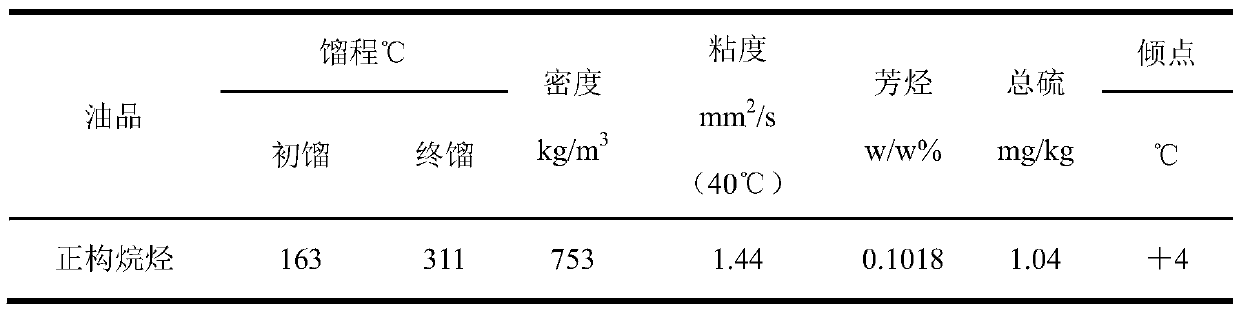

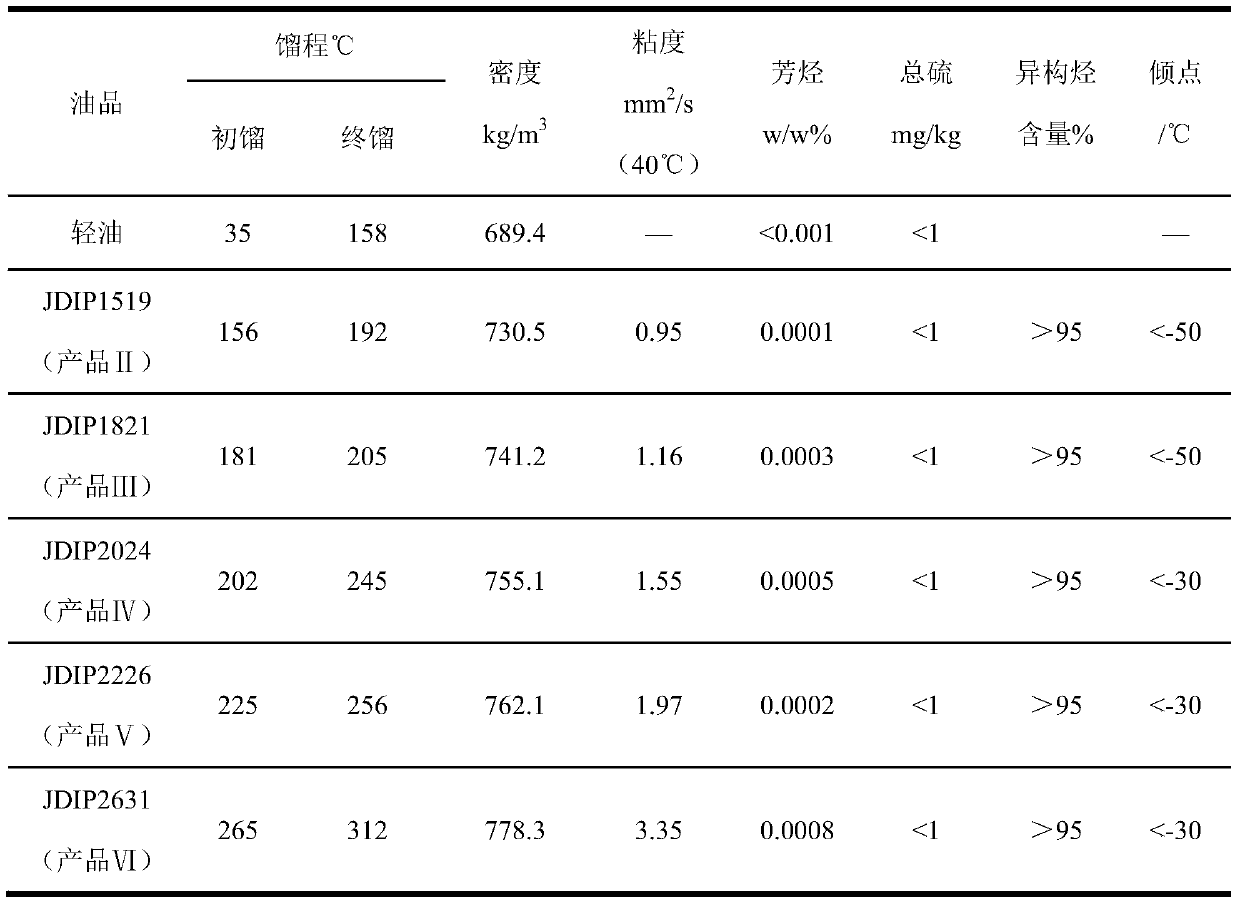

[0026] Use normal alkanes to prepare high-purity isoparaffins according to the following steps:

[0027] Step 1: Hydroisomerization

[0028] After mixing n-paraffin with hydrogen, pass through a heat exchanger and enter a heating furnace for heating. After being heated to the reaction temperature, enter the isomerization reactor with catalyst I. In the isomerization reactor, contact with catalyst I for different Structure reaction, catalyst I is a precious metal Pt, La type catalyst with a pore volume of 0.12~0.35ml / g and a specific surface area of 150~240m 2 / g. During the reaction, the n-alkane molecules enter the pores of the catalyst I molecular sieve with a certain spatial structure, and through contact with the active metal, the molecules undergo hydrogenolysis under the action of hydrogen, and the molecular chain segment after hydrogenolysis is very short It will be grafted onto the main chain within time, and hydrogen will be removed at the same time. The hydrogen will pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com