Biogas slurry pretreatment method of lignocellulosic biomass and method for producing biogas

A technology of lignocellulose and biomass, which is applied in the field of efficient resource utilization of organic solid waste, can solve the problems that biogas slurry cannot be fully utilized, high pretreatment cost, poor operability, etc., and solve the difficulty of comprehensive utilization of straw. , The method is simple, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the biogas slurry pretreatment method of a kind of lignocellulosic biomass in the present embodiment is carried out according to the following steps:

[0025] Step a, drying the corn stalks at 60°C, pulverizing them, and passing them through a 40-mesh sieve;

[0026] Step b, using the biogas slurry produced by anaerobic fermentation as a pretreatment bacterial agent; then adding the rice straw treated in step a according to the ratio of solid-to-liquid ratio of 5:100, 10:100, and 20:100, at room temperature (20 ~ Under the condition of 30° C., the rapid stirring treatment was carried out at a speed of 300 r / min for 2 minutes, and the treatment was left standing still for 24 hours.

[0027] The method for lignocellulosic biomass biogas conversion in the present embodiment is carried out according to the following steps:

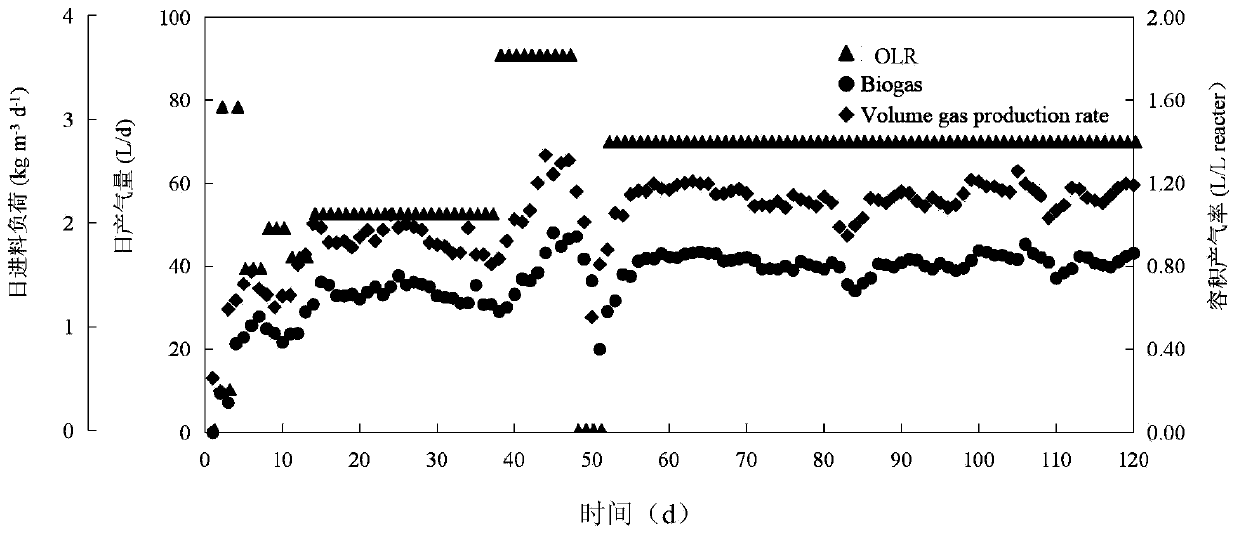

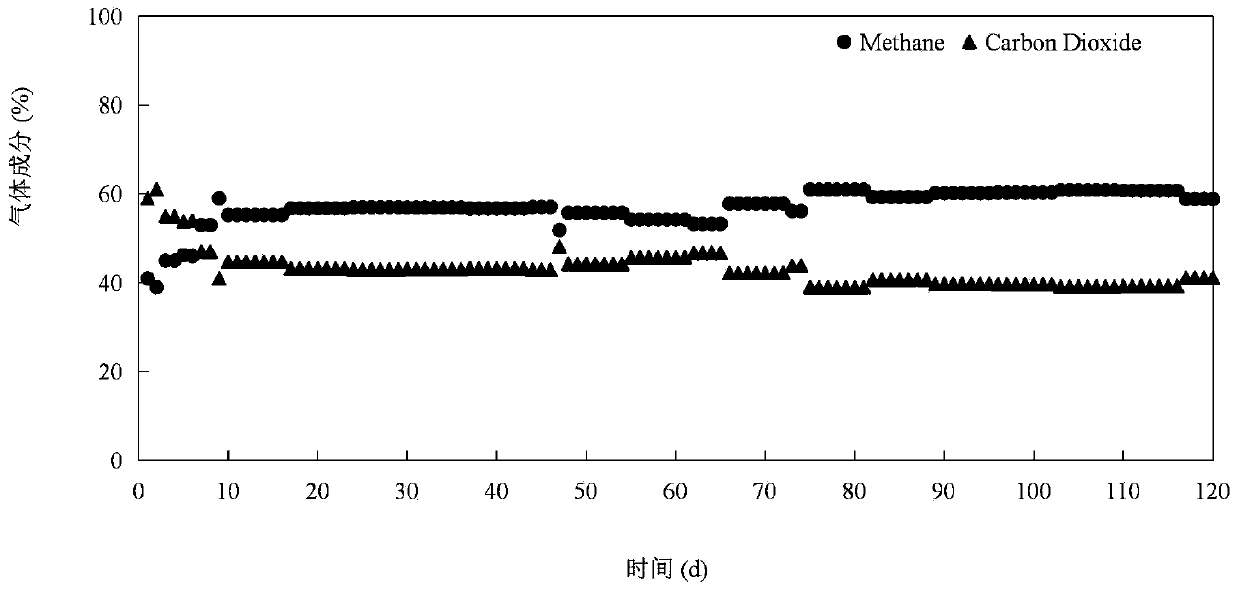

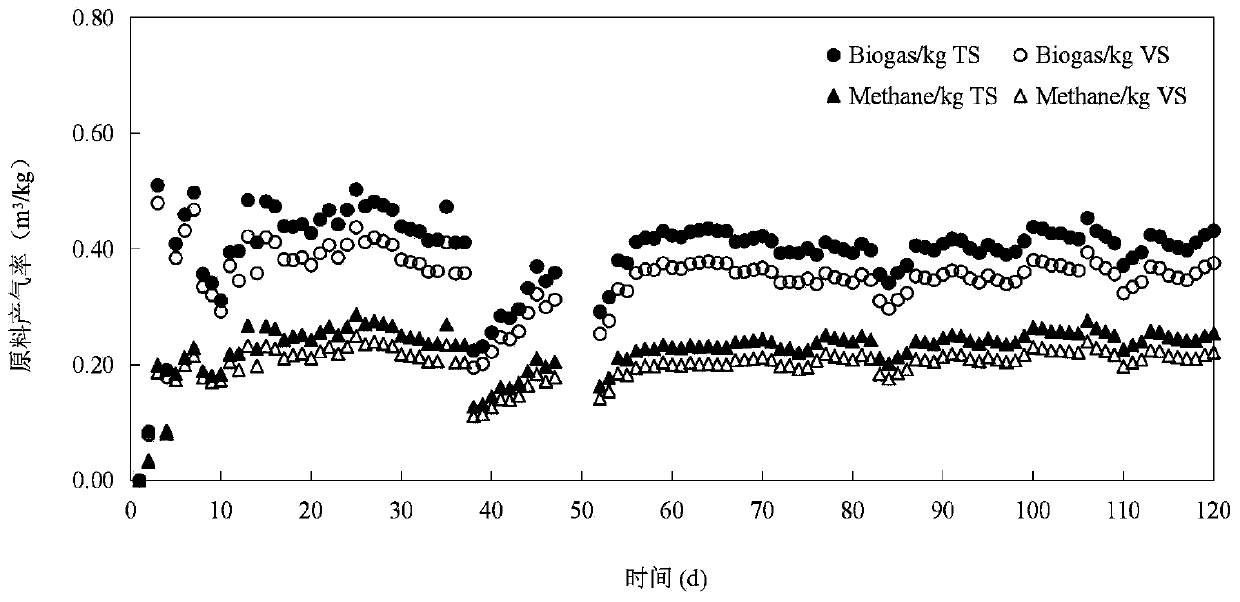

[0028] Use the lignocellulosic biomass treated by the above-mentioned biogas slurry pretreatment method as the substrate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com