Filled jacquard mesh fabric and manufacturing method thereof

A production method and filling technology, which is applied to flat warp knitting machines, textiles, papermaking, knitting, etc., can solve the problems of single product structure, poor air permeability, and small support force, and achieve soft hand feeling, good line retention, The effect of strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

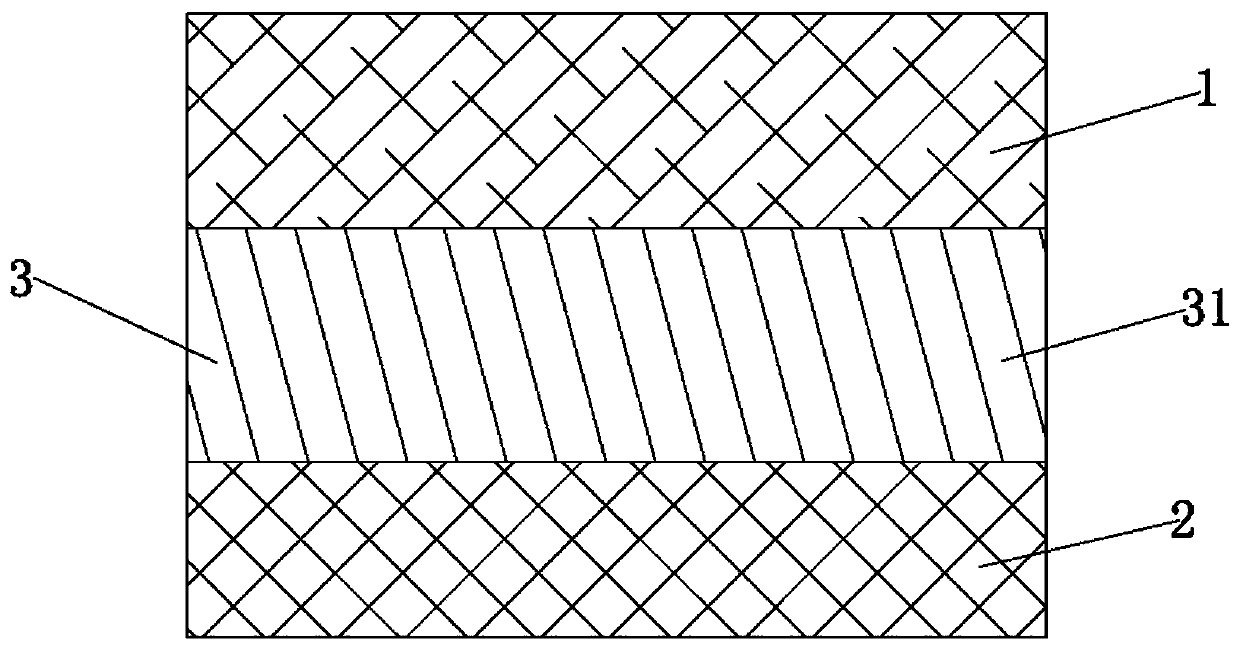

[0037] like figure 1 As shown, a filled jacquard mesh includes a mesh body integrally knitted by a double-needle sheet / double jacquard creel warp knitting machine, and the mesh body includes a surface layer 1, a bottom layer 2 and a The bonding layer 3 of the surface layer 1 and the bottom layer 2, the bonding layer 3 includes a jacquard layer 31,

[0038] The jacquard layer 31 is formed by interweaving 200D CD glossy low elastic yarn and 200D CD glossy low elastic yarn.

[0039] The surface layer 1 is formed by interweaving 50D transparent yarn and 50D transparent yarn.

[0040] The bottom layer 2 is interwoven with 150D polyester low-elasticity yarn and 150D polyester low-elasticity yarn.

[0041] like Image 6 As shown, the mesh body is made by a filling needle method, and the filling needle method is that the surface layer 1 has needles, and the bottom layer 2 does not take needles.

[0042] The present embodiment provides a method for making a filled jacquard mesh, co...

Embodiment 2

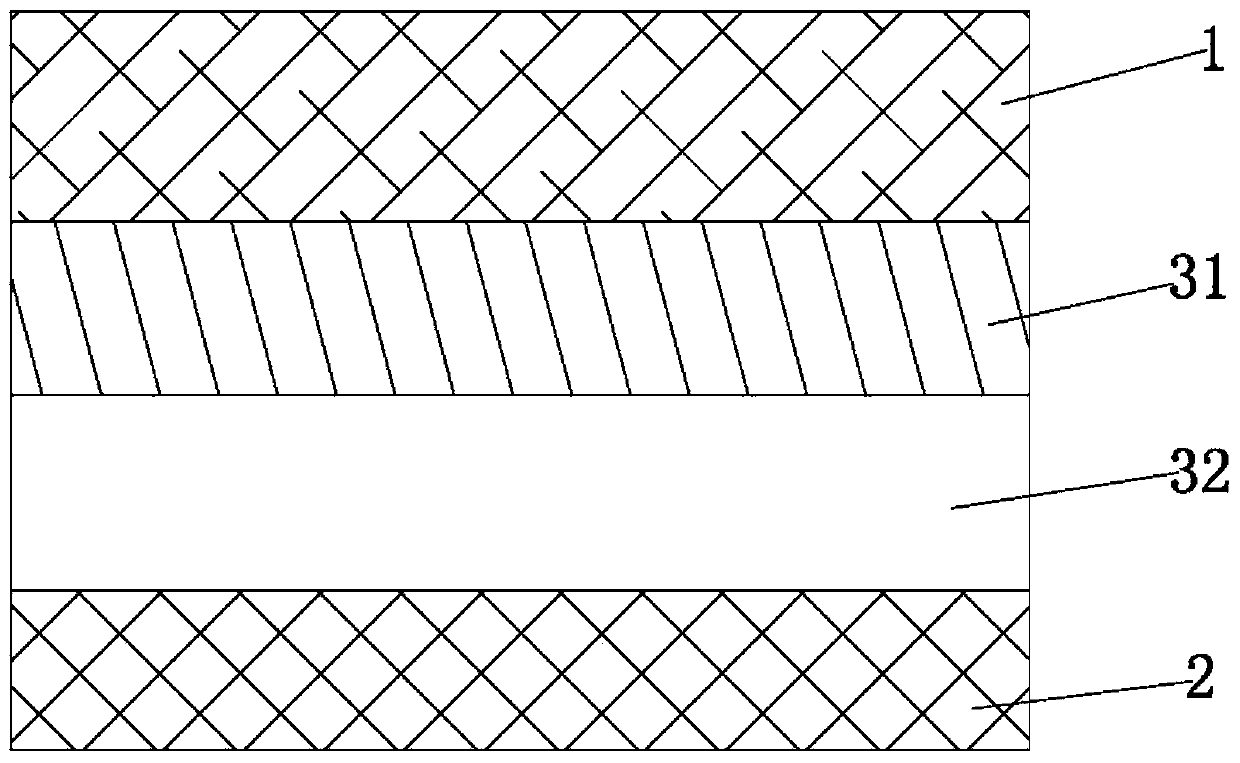

[0053] like figure 2 As shown, a filled jacquard mesh includes a mesh body integrally knitted by a double-needle sheet / double jacquard creel warp knitting machine, and the mesh body includes a surface layer 1, a bottom layer 2 and a The bonding layer 3 of the surface layer 1 and the bottom layer 2, the bonding layer 3 includes a jacquard layer 31, and the jacquard layer 31 is interwoven with 200D CD glossy low-elastic yarns and 200D CD glossy low-elasticity yarns.

[0054] The surface layer 1 is formed by interweaving 64D transparent yarn and 64D transparent yarn.

[0055] The bottom layer 2 is interwoven with 150D polyester low-elasticity yarn and 150D polyester low-elasticity yarn.

[0056] like Figure 5 As shown, the mesh body is made by a filling needle method, and the filling needle method is that the surface layer 1 does not take needles, and the bottom layer 2 takes needles.

[0057] The bonding layer 3 further includes a fixing layer 32, and the fixing layer 32 is...

Embodiment 3

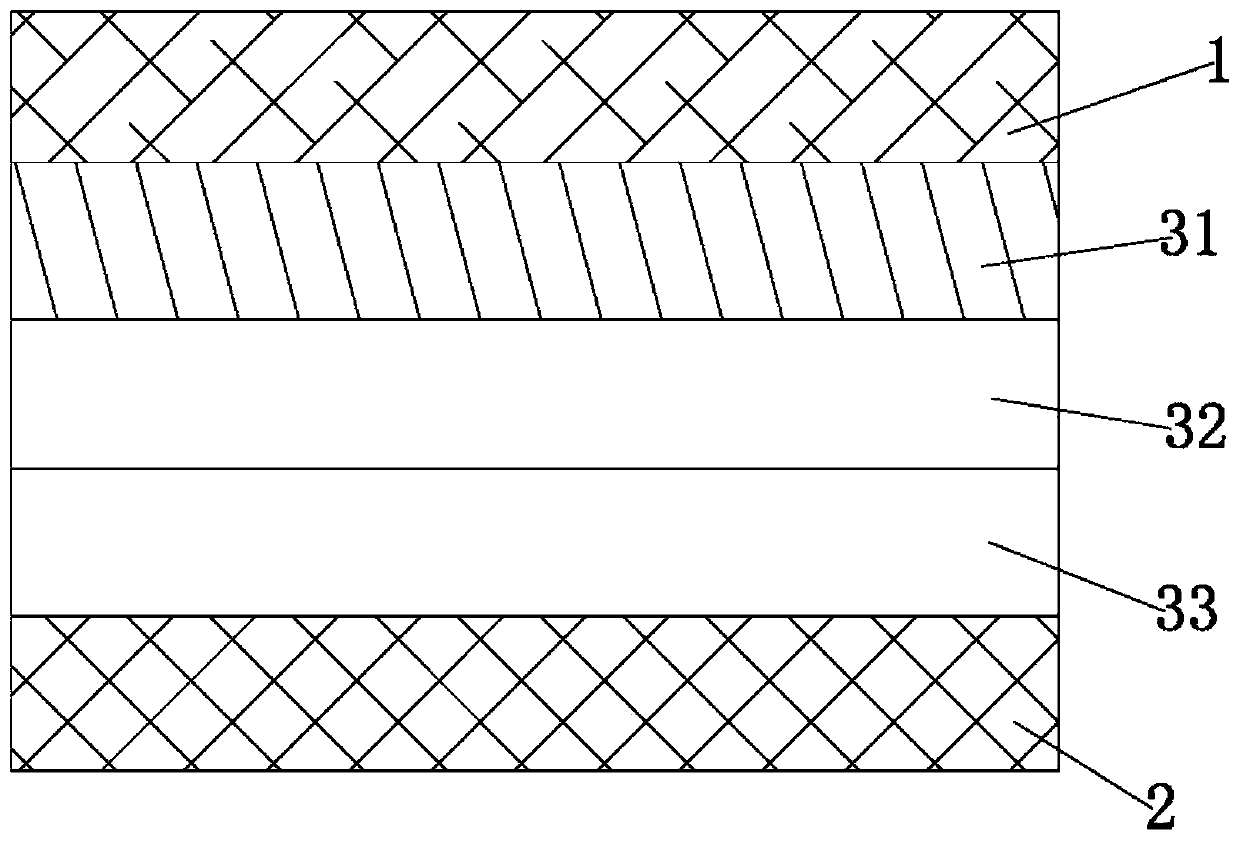

[0070] like image 3 As shown, a filled jacquard mesh includes a mesh body integrally knitted by a double-needle sheet / double jacquard creel warp knitting machine, and the mesh body includes a surface layer 1, a bottom layer 2 and a The bonding layer 3 of the surface layer 1 and the bottom layer 2, the bonding layer 3 includes a jacquard layer 31, and the jacquard layer 31 is interwoven with 200D CD glossy low-elastic yarns and 200D CD glossy low-elasticity yarns.

[0071] The surface layer 1 is formed by interweaving 64D transparent yarn and 64D transparent yarn.

[0072] The bottom layer 2 is interwoven with 150D polyester low-elasticity yarn and 150D polyester low-elasticity yarn.

[0073] like Image 6 As shown, the mesh body is made by a filling needle method, and the filling needle method is that the surface layer 1 has needles, and the bottom layer 2 does not take needles.

[0074] The bonding layer 3 further includes a fixing layer 32, and the fixing layer 32 is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com