Assembly type unilateral precast wall panel of underground station and vertical-rotation installation method

A technology for prefabricated wall panels and underground stations, applied in excavation, underwater structures, water conservancy projects, etc., can solve problems such as difficulty in installing prefabricated components in place, affecting installation efficiency, etc., and achieve the effect of being beneficial to plane layout and preventing mold expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

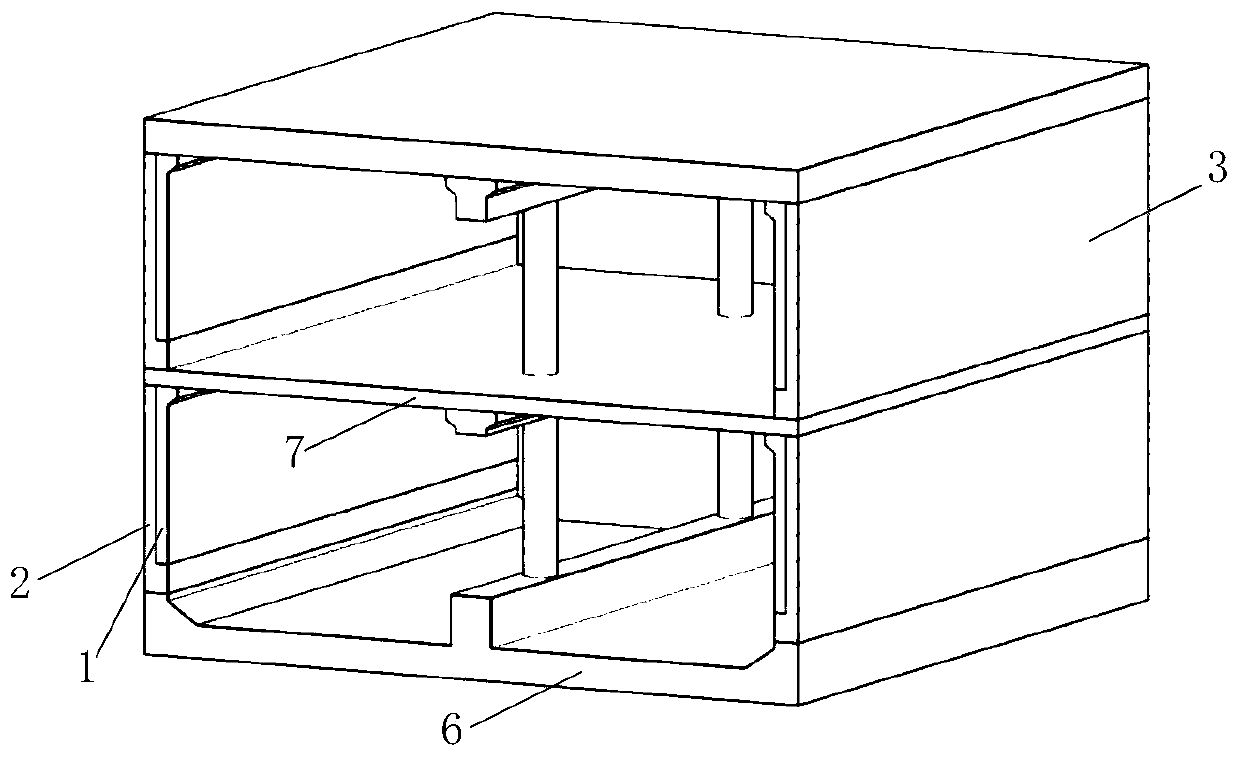

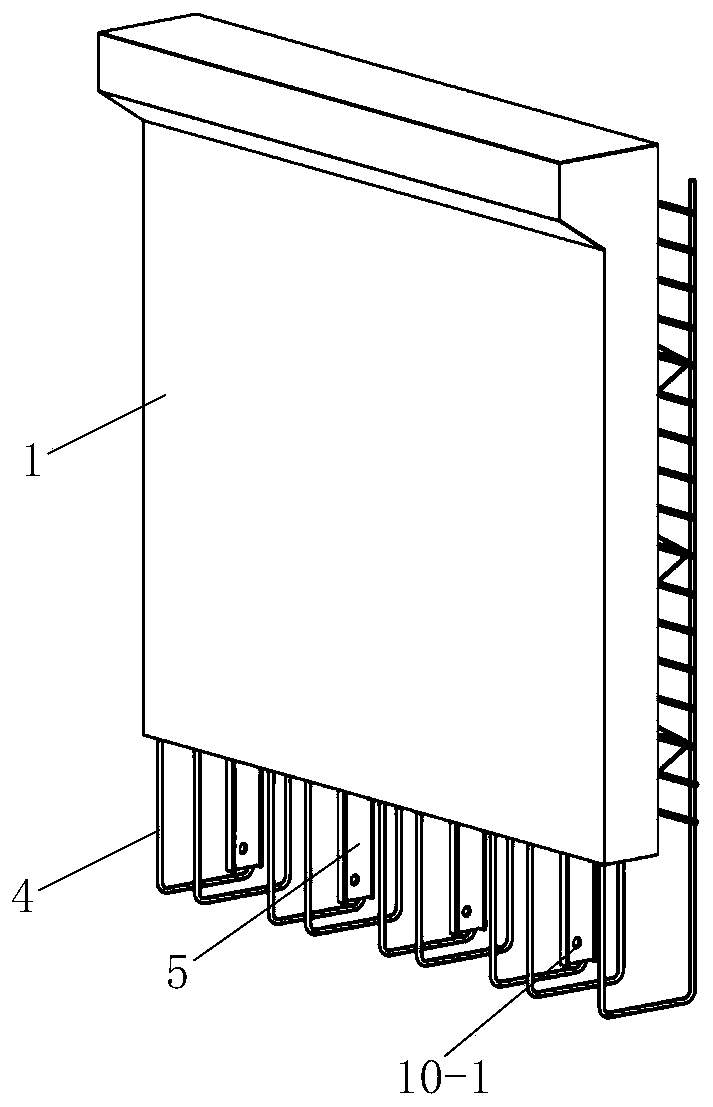

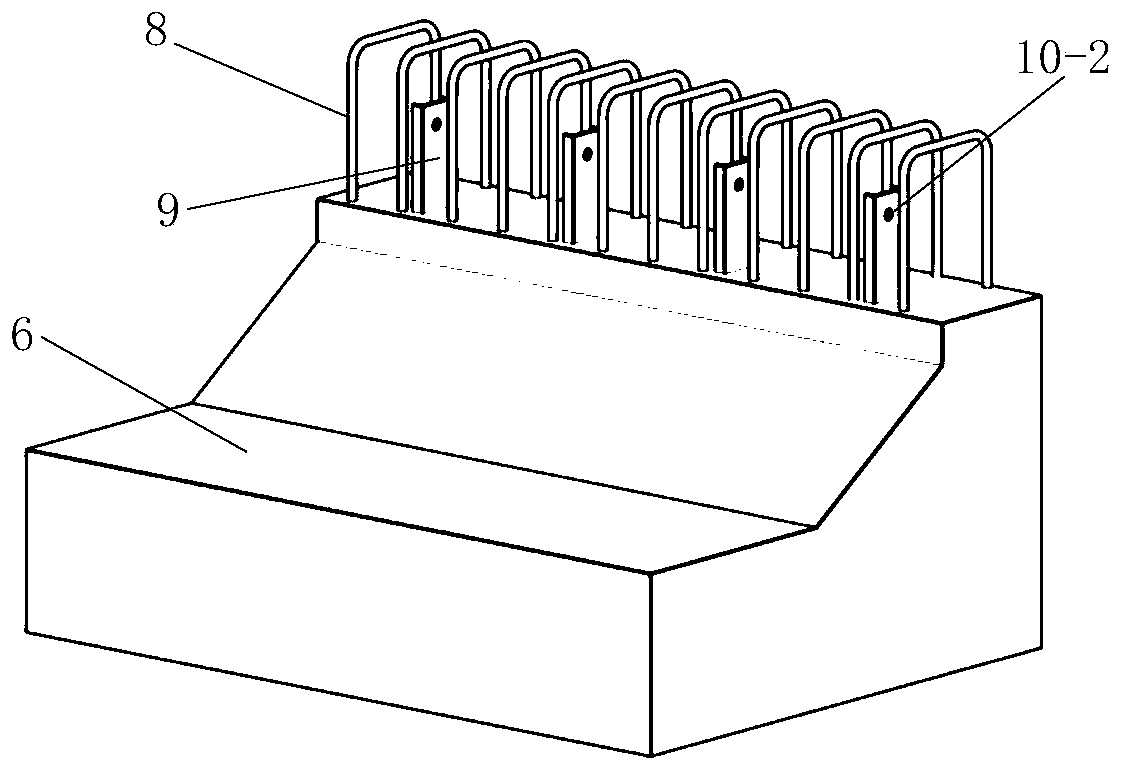

[0022] The present invention includes a single-sided prefabricated wall panel 1 located on the inside, a cast-in-place concrete 2 located on the outside, and a laminated integral wall panel 3 composed of a single-sided prefabricated wall panel 1 and cast-in-place concrete 2; wherein, the single-sided prefabricated wall Vertical upper U-shaped steel bars 4 protrude from the bottom of the board 1, and upper channel steel legs 5 are arranged between the upper U-shaped steel bars 4, so that they can support a single-sided prefabricated wall panel 1 in an upright installation state The cast-in-place or prefabricated bottom plate 6 or the superimposed cast-in-place middle plate 7 in the foundation pit protrudes from the bottom of the single-sided prefabricated wallboard 1 on the superimposed surface of the laminated integral wallboard 3 parts The lower U-shaped steel bar 8 corresponding to the U-shaped steel bar 4 and the lower channel steel leg 9 corresponding to the upper channel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com