Novel high-pressure composite gas cylinder

A high-pressure, gas cylinder technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of low production efficiency, carbon fiber cutting, heavy bottle weight, etc. The effect of improving service life and strong connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are known technologies known to those skilled in the art, such as gluing, welding, blow molding, screw connection, bolt-nut connection, and riveting.

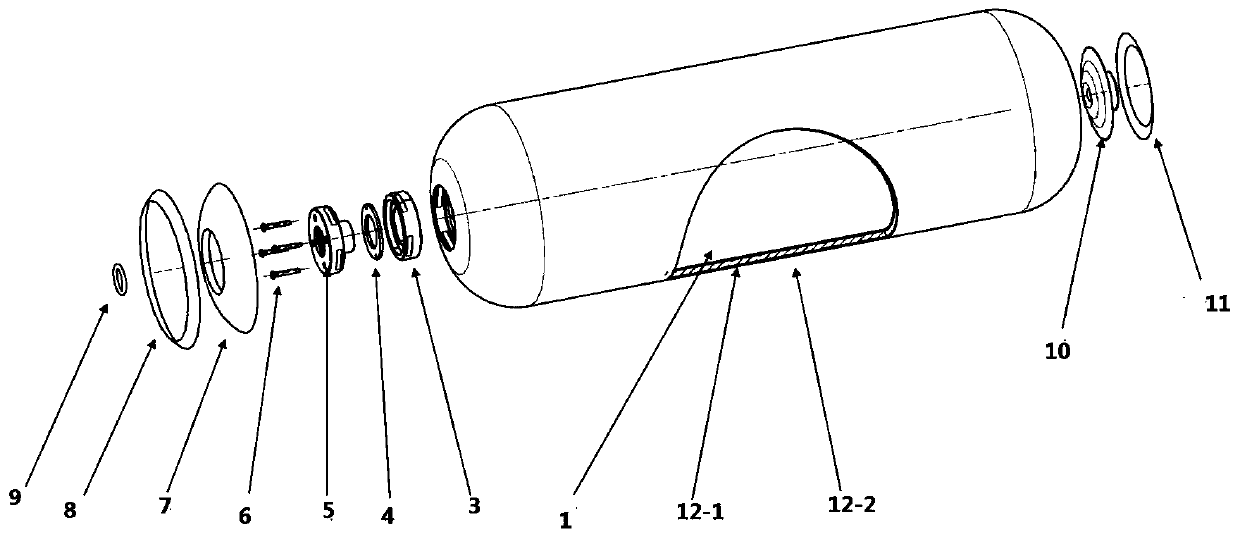

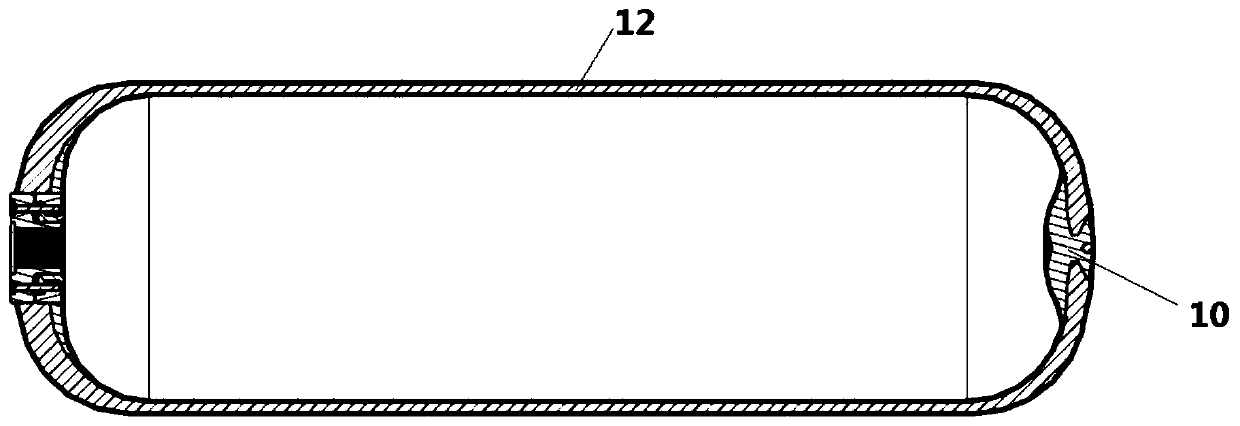

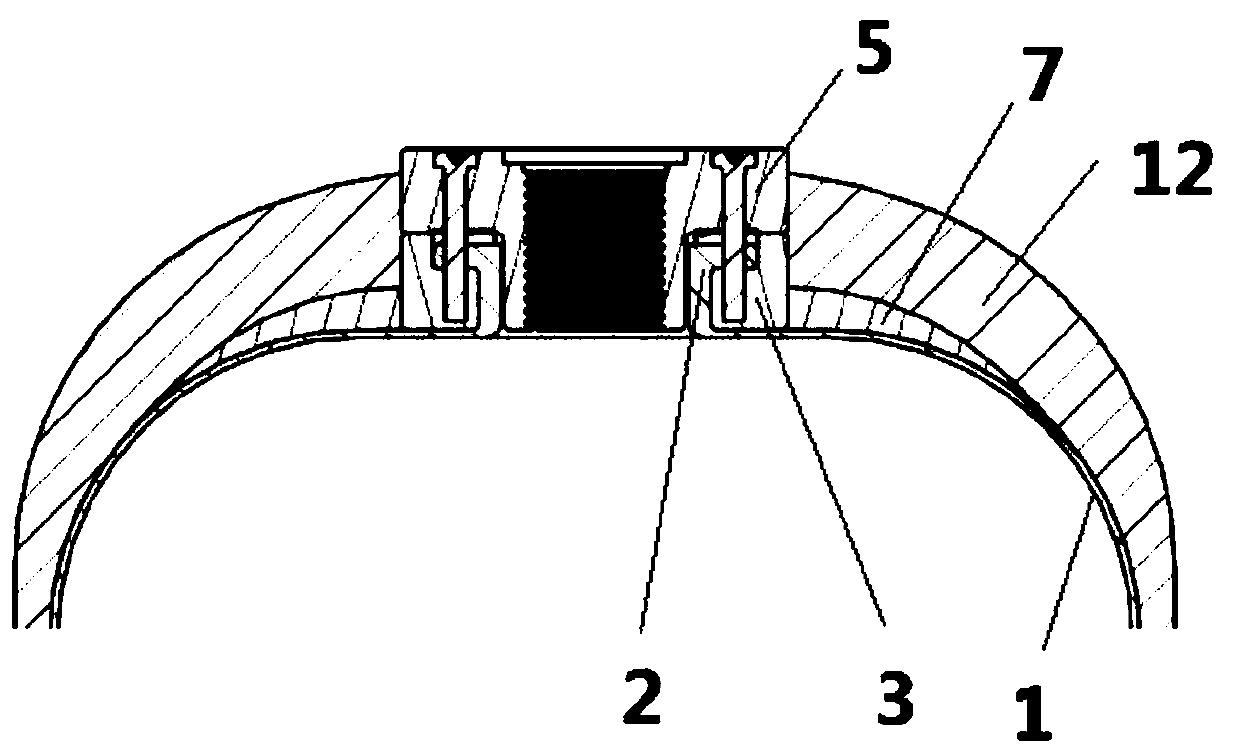

[0049] It can be seen from the accompanying drawings that a new type of high-pressure composite gas cylinder includes an inner tank, a bottle mouth, a sealing structure, a lining, a top tape, a sealing ring, a bottom flange, a bottom tape, and a winding layer;

[0050] The section of the mouth of the bottle is in the shape of "I", the mouth of the bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com