A waste drying device for waste incineration power generation

A technology of waste incineration and drying device, which is applied in drying, dryer, heating device and other directions, can solve the problems of simple rotating rod, low calorific value, and inability to spin dehydration of garbage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

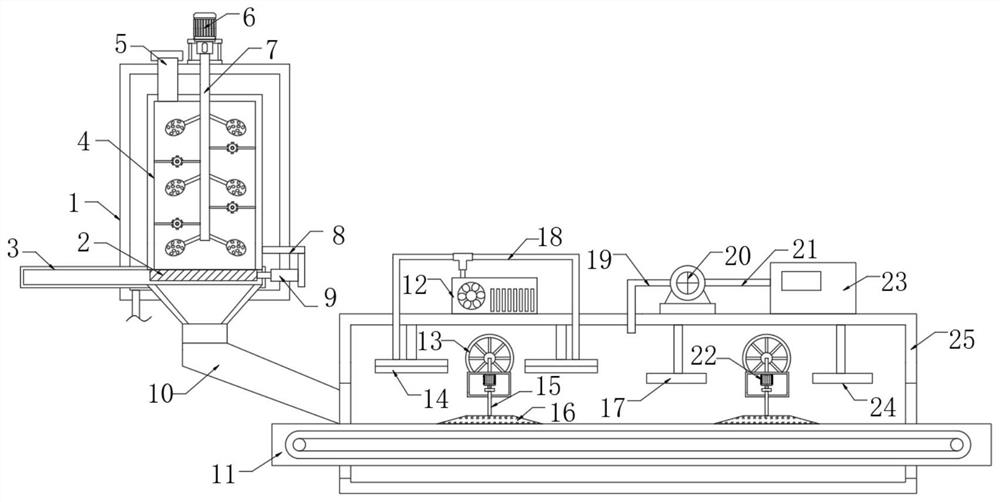

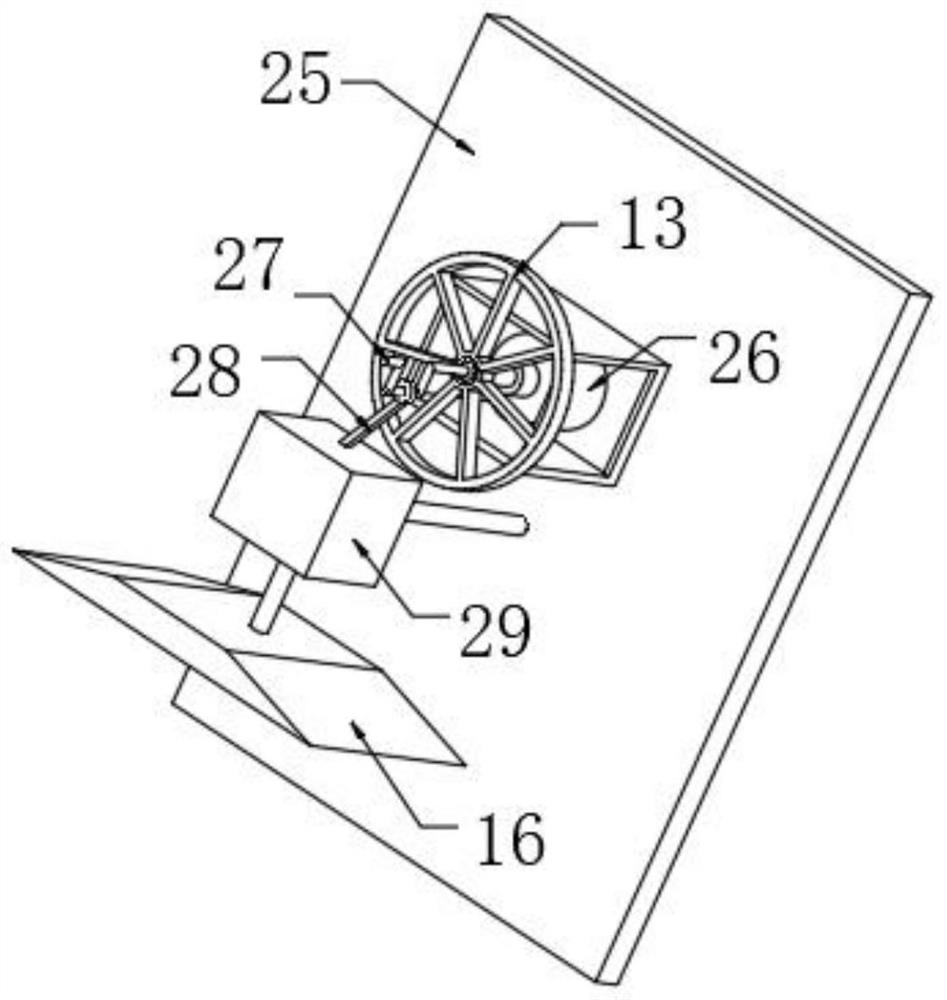

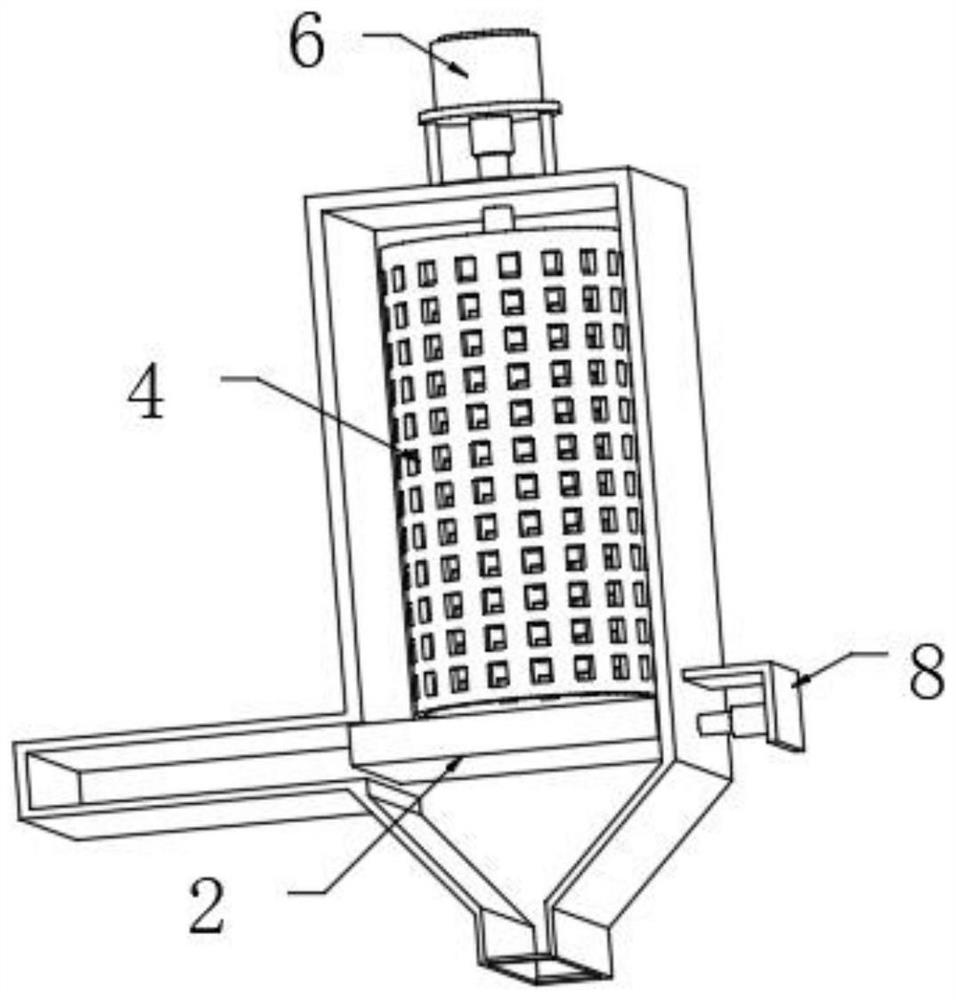

[0031] Refer Figure 1-4 , A waste drying apparatus for waste incineration, including the dewatering tank 1 and the drying box 25, the inner wall welded with the dehydration tank 1, and the top outer wall of the dehydration tank 1 is fixed by screws 6, The output shaft of the motor 6 is connected to the coupling having the first turn rod 7, and the outer wall of the first rotor 7 welded the equal distance distribution, and the outer wall of the stirring plate 31 welded and equally distributed. The connecting rod 30 is provided between the projections, the outer wall of the first rotary rod 7 and the inner wall of the dewatering cylinder 4, and one end of the connecting rod 30 is fixed to the first rotor 7, and the outer wall of the connecting rod 30 is connected by a bearing. 32. The outer wall of the dehydration tank 1 is fixed to the connecting box 3 by the screw, and the outer outer wall of the dewatering cylinder 4 welded is provided with a web, and the top outer wall of the dr...

Embodiment 2

[0038] Refer Figure 5 , A waste drying device for a waste incineration power generation includes a purifier 34, a purifier 34 that is fixed to the outer wall of the dewatering tank 1 by a screw, and the inner wall of the input end of the purge tank 1 and the inner wall of the dewatering tank 1 have the same one. Guarantee 33.

[0039] Connect the device to the power supply, and the waste is included in the water supply port 15 into the dewater 4, open the first motor 6, the first motor 6 drives the first rotor 7 to rotate, and the stirring plate 31 and the runner 32 can be After sufficient rotation dehydration of the garbage, after the dehydration is ended, the hydraulic rod 9 is connected to the hydraulic system, and the longitude of the hydraulic rod 9 is adjusted, the rubbish is discharged from the lower tank 10, open the transfer station 11, and the garbage start transmission The hot fan 12 is opened, and the hot air is blown on the surface of the garbage by the hot air disks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com