Device for measuring specific resistance parameter of sludge, use method and application thereof

A sludge specific resistance and parameter technology, applied in the direction of weighing by removing certain components, can solve the problems of large counting errors and complicated operations, and achieve the effect of reducing counting errors and stabilizing the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

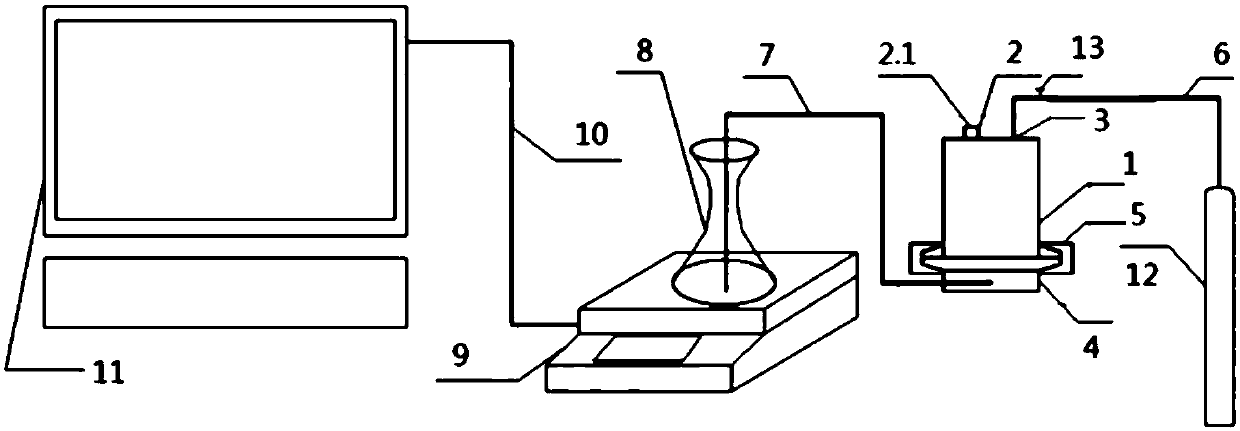

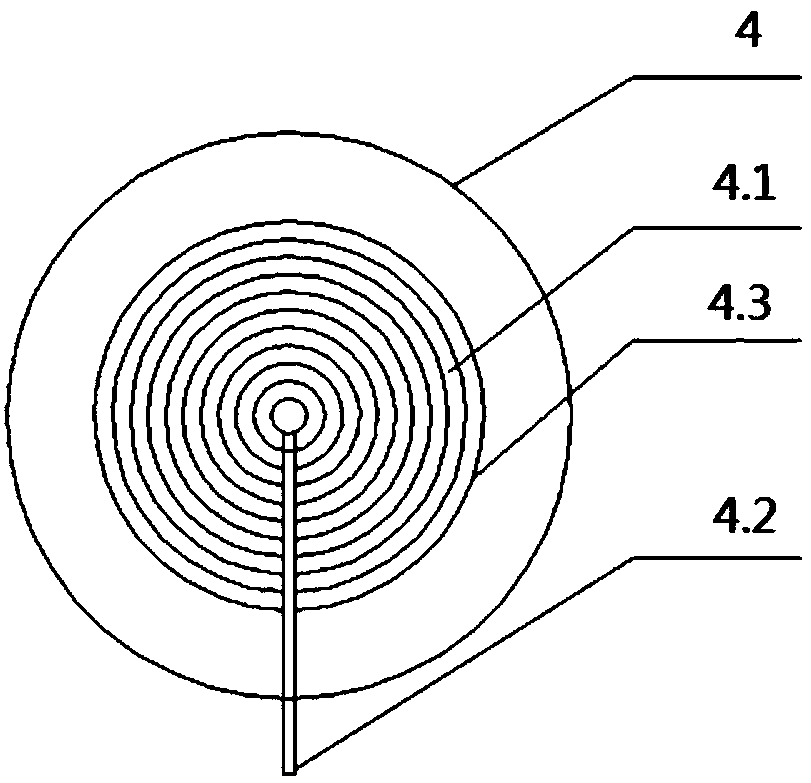

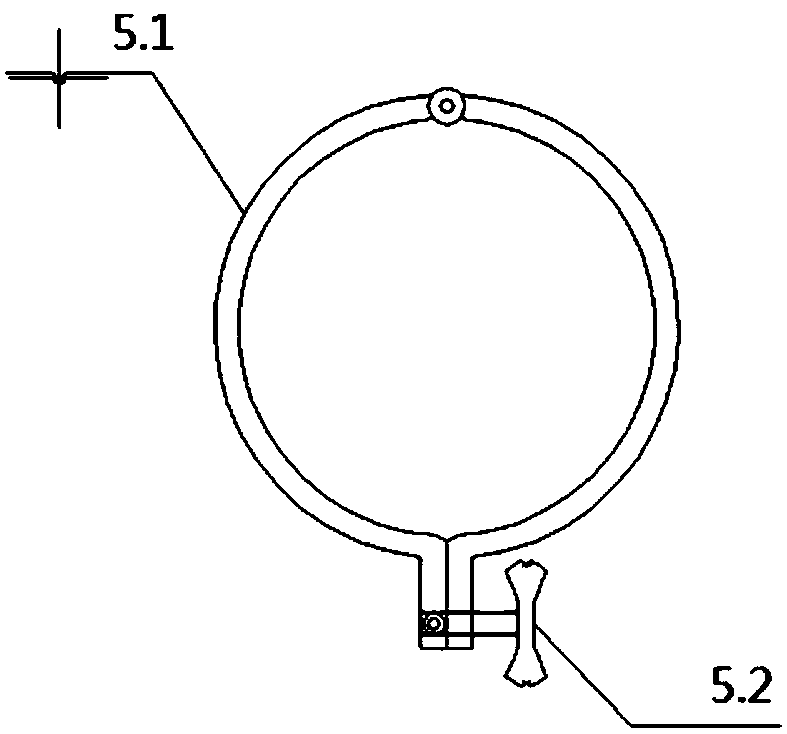

[0057] Such as Figure 1-3 As shown, the device for measuring the specific resistance parameter of sludge in this embodiment includes: sealing body 1, sample inlet 2, sample inlet sealing cover 2.1, air inlet 3, base 4, fastener 5 (clamp 5.1 and Bolt 5.2), air intake pipe 6, collection pipe 7, collection bottle 8, analytical balance 9, data line 10, computer system 11, nitrogen bottle 12 and nitrogen switch 13; said base is provided with filtrate collection tank 4.1, filtrate outlet 4.2 And sealing ring 4.3.

[0058] One end of the inlet pipe 6 is connected to the nitrogen cylinder 12 , and the other end is connected to the top of the sealed body 1 . The sealing body 1 and the base 4 are connected by a clamp 5.1. The filter unit includes an inlet sealing cover 2.1, an inlet 2, a sealing body 1 and a base 4 arranged from top to bottom. One end of the collection tube 7 is connected to the filtrate outlet 4.2, and the other end is placed in the collection bottle 8 and placed a...

Embodiment 2

[0065] Such as Figure 4 As shown, the device for measuring sludge specific resistance parameters based on Example 1 is different in that the device also includes a pressure control unit, specifically including a pressure gauge 14 and a pressure control valve 15 arranged on the intake pipe 7 . The pressure gauge 14 is used to record the pressure value in the sealing body 1 . The pressure control valve 15 is used to control the pressure inside the sealing body 1 .

[0066] The device of this embodiment is used to measure the specific resistance of sludge, and the specific steps are as follows:

[0067] (1) Turn on the computer system 11 and the analytical balance 9, wet the medium-speed filter paper and place it on the base 4, place the sealing ring 4.3 in the groove of the base, and tighten the seal body 1 and the base 4 with the tightening band 5.1 .

[0068] (2) Regulate the pressure control valve 15 so that the pressure gauge 14 shows a fixed value p=60KPa.

[0069] (3)...

Embodiment 3

[0074] Based on the device for measuring the specific resistance parameter of sludge in Example 1, the difference is that the fastener is an elastic rubber ring, which is sheathed on the outer surface of the joint between the sealing body 1 and the base 4 .

[0075] The device of this embodiment is used to measure the specific resistance of sludge, and the specific steps are the same as in embodiment 2.

[0076] Using the traditional method to measure the sludge specific resistance value, artificial reading, according to the sludge specific resistance value measured each time, the average value is obtained statistically. Compared with the average value, the single relative error can reach about 37%. However, compared with the average values of the sludge specific resistance values measured by Examples 2 and 3 of the present invention, the single relative error is only about 2% at most. Therefore, using the parameter b obtained in the embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com