Organic intercalation method, organic intercalation device, organic intercalation material, organic intercalation test method, application of material, and solar panel

An organic and intercalation technology, applied in the field of materials, can solve the problems of reducing light absorption capacity, unfavorable solar cell applications, three-dimensional structure instability, etc., to improve stability and photoelectric performance, reduce the effective mass of electrons, and improve photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0032] As the background technology, because the three-dimensional geometric structure of the material is prone to collapse, the structure is unstable, and the phase transition is easy to occur, the band gap gradually increases with the phase transition, which is not conducive to light absorption, and the surface modification method and internal doping method cannot be based on Solve the problem of unstable three-dimensional geometry of materials.

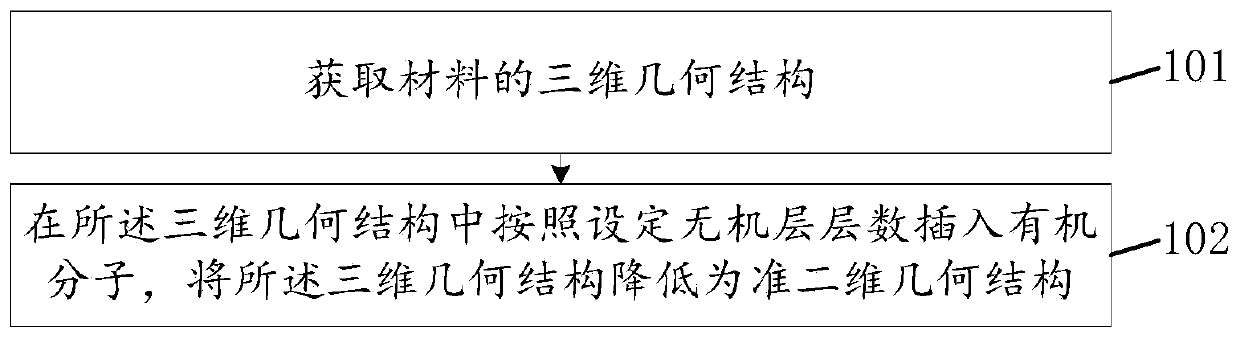

[0033] In order to solve the above problems, an embodiment of the present invention provides an organic intercalation method, such as figure 1 As shown, the method includes:

[0034] 101. Obtain the three-dimensional geometric structure of the material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com