An electrode pole piece and an electrochemical device

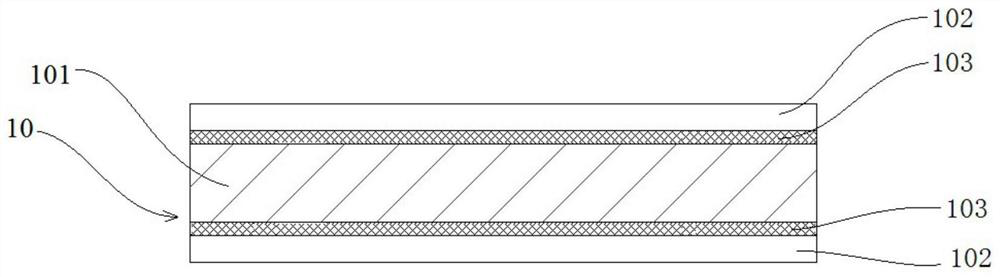

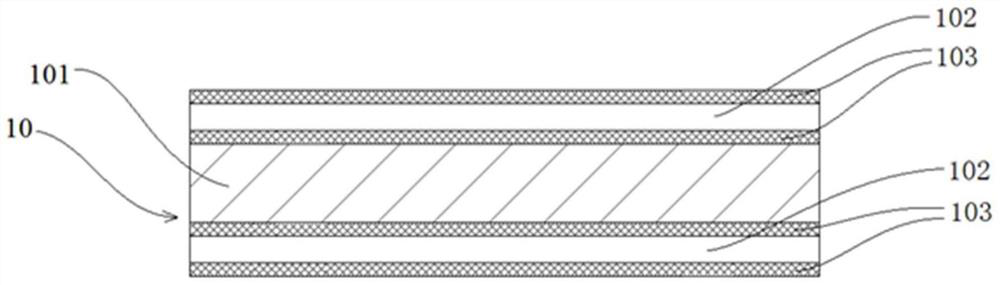

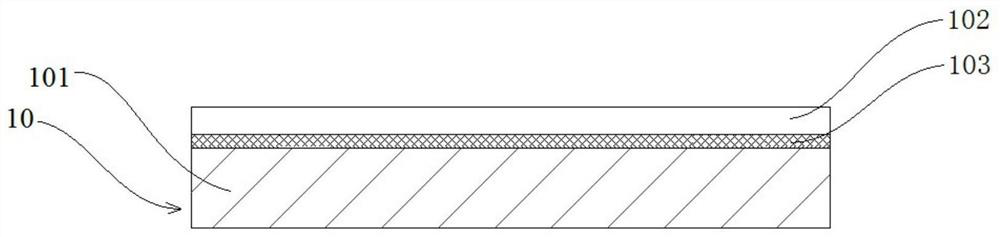

An electrode pole piece and electrode active material technology, applied in the battery field, can solve problems such as the deterioration of processing performance and electrochemical performance, and achieve the effects of improving the safety performance of piercing and improving the energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0190] The preparation method of the current collector used in the electrode pole pieces in each embodiment and comparative example is as follows:

[0191] 1. Preparation of current collector without protective layer:

[0192] Select a support layer with a certain thickness, and form a conductive layer with a certain thickness on its surface by means of vacuum evaporation, mechanical rolling or bonding.

[0193] in,

[0194] (1) The formation conditions of the vacuum evaporation method are as follows: the support layer that has been cleaned on the surface is placed in a vacuum coating room, and the high-purity metal wire in the metal evaporation room is melted and evaporated at a high temperature of 1600 ° C to 2000 ° C. The evaporated metal After passing through the cooling system in the vacuum plating chamber, it is finally deposited on the surface of the support layer to form a conductive layer.

[0195] (2) The formation conditions of the mechanical rolling method are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com