Backboard of optical display module and preparation method thereof

A technology of optical display and display panel, which is applied to housings with display/control units, electrical equipment housings/cabinets/drawers, instruments, etc. It can solve problems such as low production efficiency, large pollution, and single functionality of the backplane. Achieve high production efficiency, low production cost, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

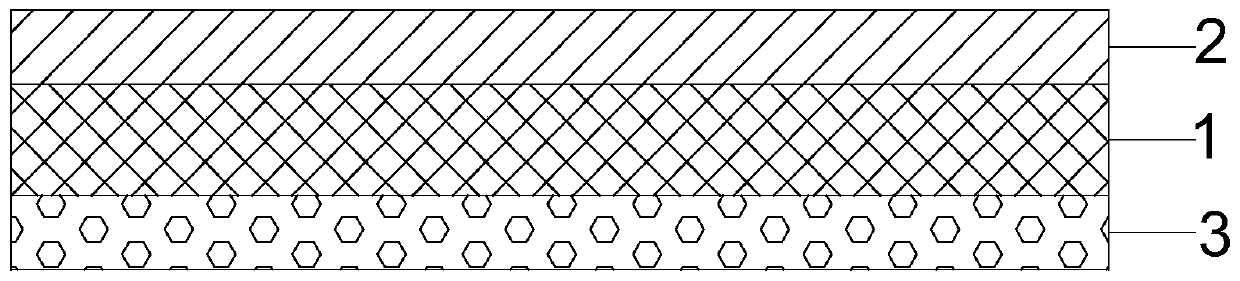

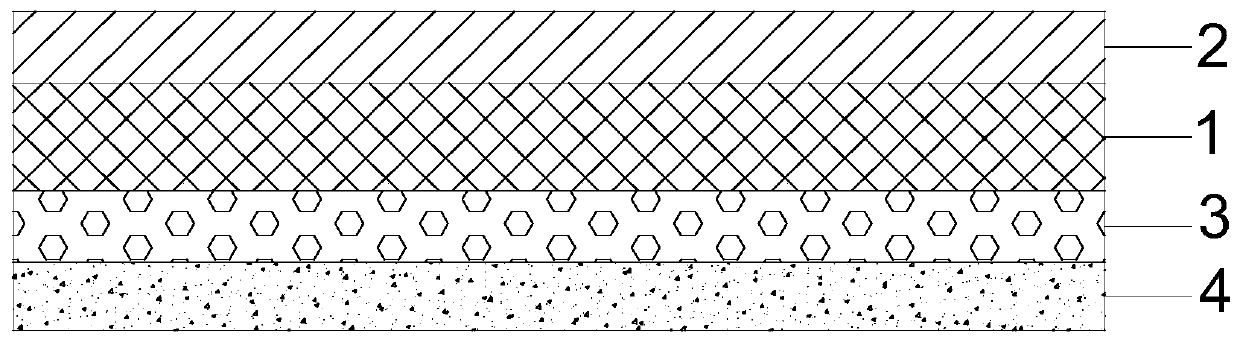

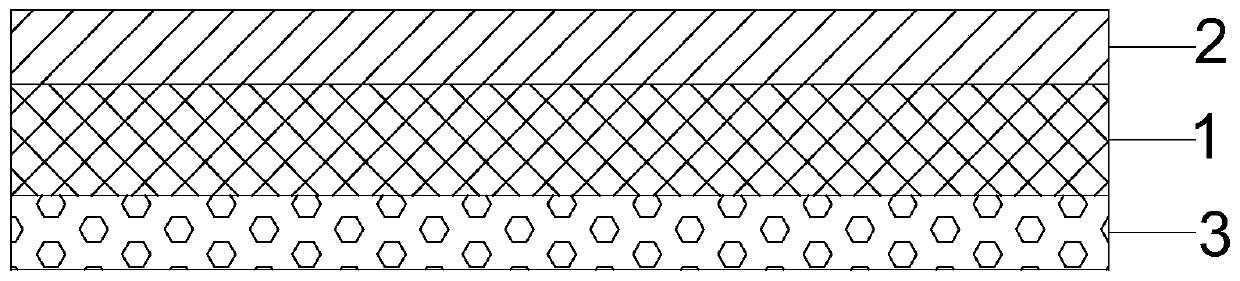

[0030] Such as figure 1 As shown, the backplane provided by this embodiment 1 includes a light reflective coating 2, a substrate 1 and a conductive anti-oxidation coating 3 arranged in sequence from top to bottom; the light reflective coating 2 is arranged on the substrate 1 near the light guide plate On one side, the conductive anti-oxidation coating 3 is arranged on the side of the substrate 1 away from the light guide plate;

[0031] Among them, the light reflective coating is a coating formed by adding titanium dioxide and additives with epoxy resin as the base material. Specifically, in this embodiment 1, the raw materials for the preparation of the light reflective coating include the following components in parts by mass: 35 parts of epoxy resin, 25 parts of water, 5 parts of dispersant, 5 parts of thickener, 10 parts of titanium dioxide share. After mixing and stirring the above-mentioned raw materials evenly, a light-reflective coating slurry is prepared; then, the ...

Embodiment 2

[0034] Such as figure 1 As shown, the backplane provided by this embodiment 2 includes a light reflective coating 2, a substrate 1 and a conductive anti-oxidation coating 3 arranged in sequence from top to bottom; the light reflective coating 2 is arranged on the substrate 1 near the light guide plate On one side, the conductive anti-oxidation coating 3 is arranged on the side of the substrate 1 away from the light guide plate;

[0035] Among them, the light reflective coating is a coating formed by adding titanium dioxide and additives with epoxy resin as the base material. Specifically, in this embodiment 2, the preparation raw material of light reflective coating comprises the following components of mass fraction: 55 parts of epoxy resins, 35 parts of water, 8 parts of dispersants, 6 parts of thickeners, 35 parts of titanium dioxide share. After mixing and stirring the above-mentioned raw materials evenly, a light-reflective coating slurry is prepared; then, the light-re...

Embodiment 3

[0038] Such as figure 1 As shown, the backplane provided in Example 3 includes a light reflective coating 2, a substrate 1, and a conductive anti-oxidation coating 3 arranged in sequence from top to bottom; the light reflective coating 2 is arranged on the substrate 1 near the light guide plate On one side, the conductive anti-oxidation coating 3 is arranged on the side of the substrate 1 away from the light guide plate;

[0039] Among them, the light reflective coating is a coating formed by adding titanium dioxide and additives with epoxy resin as the base material. Concretely, in this embodiment 3, the preparation raw material of light reflective coating comprises the following components of mass fraction: epoxy resin 75 parts, water 50 parts, dispersant 10 parts, thickener 10 parts, titanium dioxide 50 parts share. After mixing and stirring the above-mentioned raw materials evenly, a light-reflective coating slurry is prepared; then, the light-reflective coating slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com