A waste secondary screening system in the recycling process of gypsum board waste

A technology of gypsum board and secondary sieve, which is applied in the direction of separating solids from solids with airflow, filtering and sieving, and solid separation, etc., which can solve the problem of incomplete separation of gypsum blocks and paper scraps for face protection, and low recycling rate of gypsum blocks , Gypsum board quality decline and other issues, to achieve the effect of improving quality, reducing energy consumption, and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

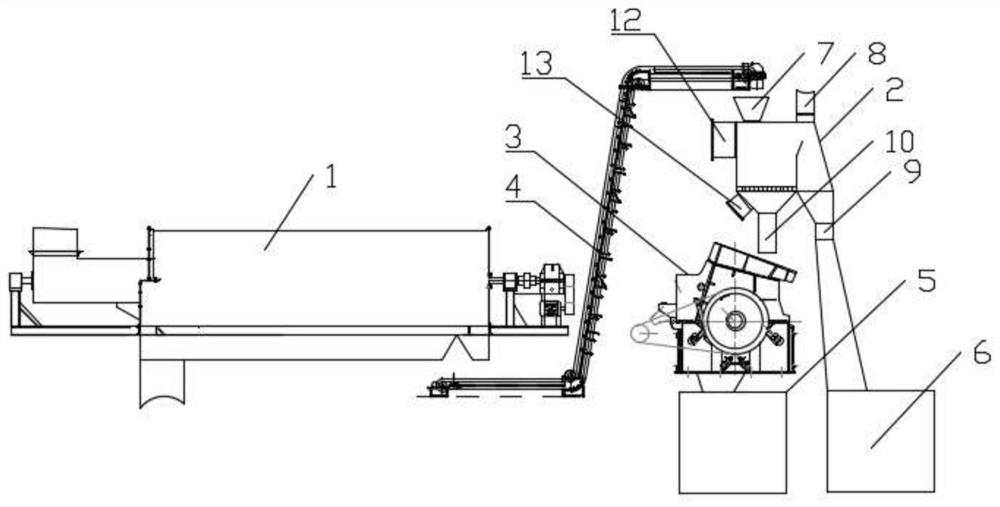

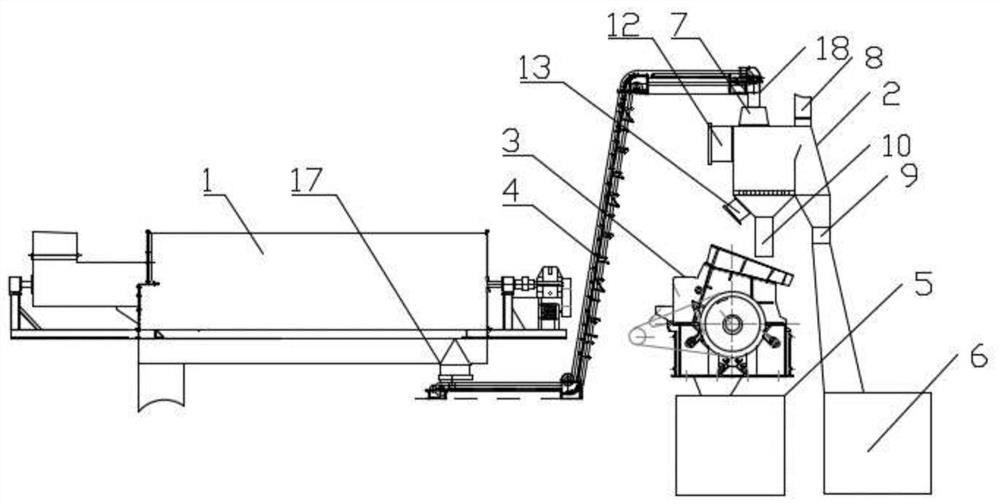

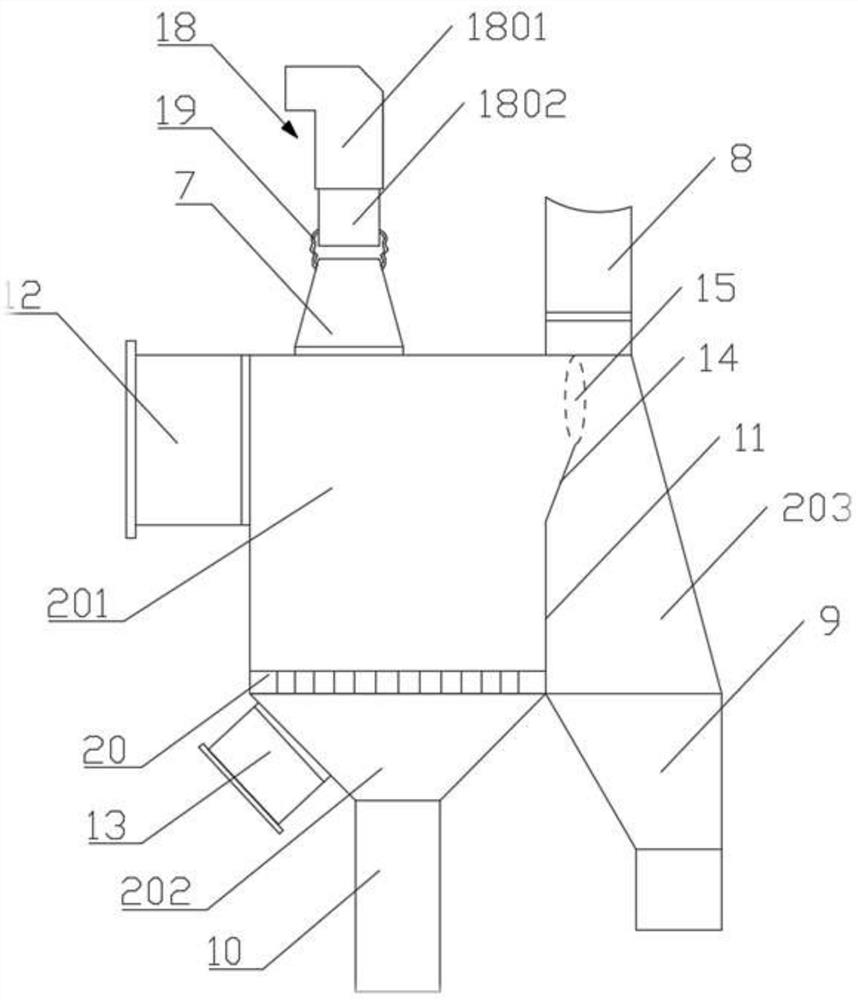

[0037] It includes a rotary screen 1, a gypsum paper waste separation box 2 and a crusher 3. The gypsum paper waste separation box 2 is provided with a feeding port 7, a dust collection interface 8, a paper waste outlet 9, and a gypsum paper waste connected to the feed port of the crusher 3. The block outlet 10, the coarse material chute of the rotary screen 1 and the feeding port 7 are connected by the inclination conveyor 4, the discharge port of the crusher 3 is connected with the gypsum powder collection box 5, and the paper scrap outlet 9 is connected with the surface protection paper scrap collection Box 6, a gypsum paper waste separation mechanism is installed in the gypsum paper waste separation box 2.

[0038]After the gypsum board waste is screened by the rotary screen 1, the larger blocks are discharged from the coarse material chute, and the discharged gypsum blocks fall on the horizontal input end at the bottom of the inclination conveyor 4. Through the operation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com