Application of toluene diisocynate kettle residues, method for preparing graphite from toluene diisocynate kettle residues, graphite and application of graphite

A technology of toluene diisocyanate and kettle residues, which is applied in the field of chemical waste recycling and can solve the problem of low economic benefits and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

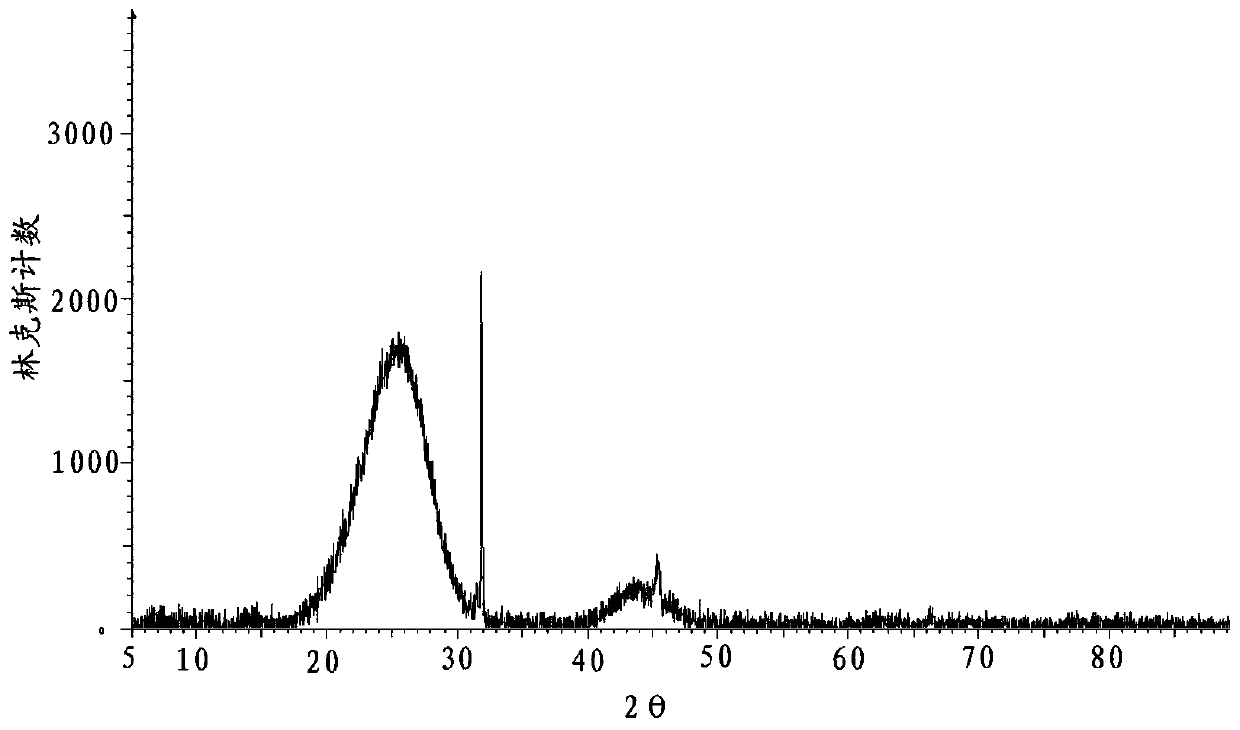

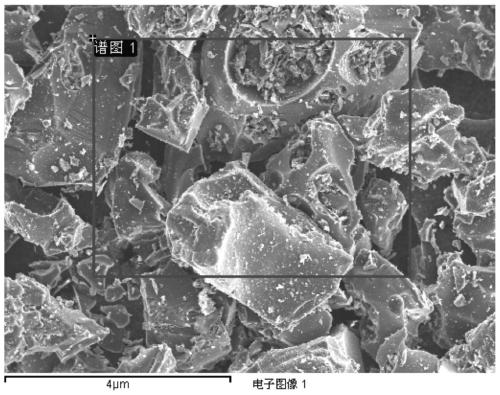

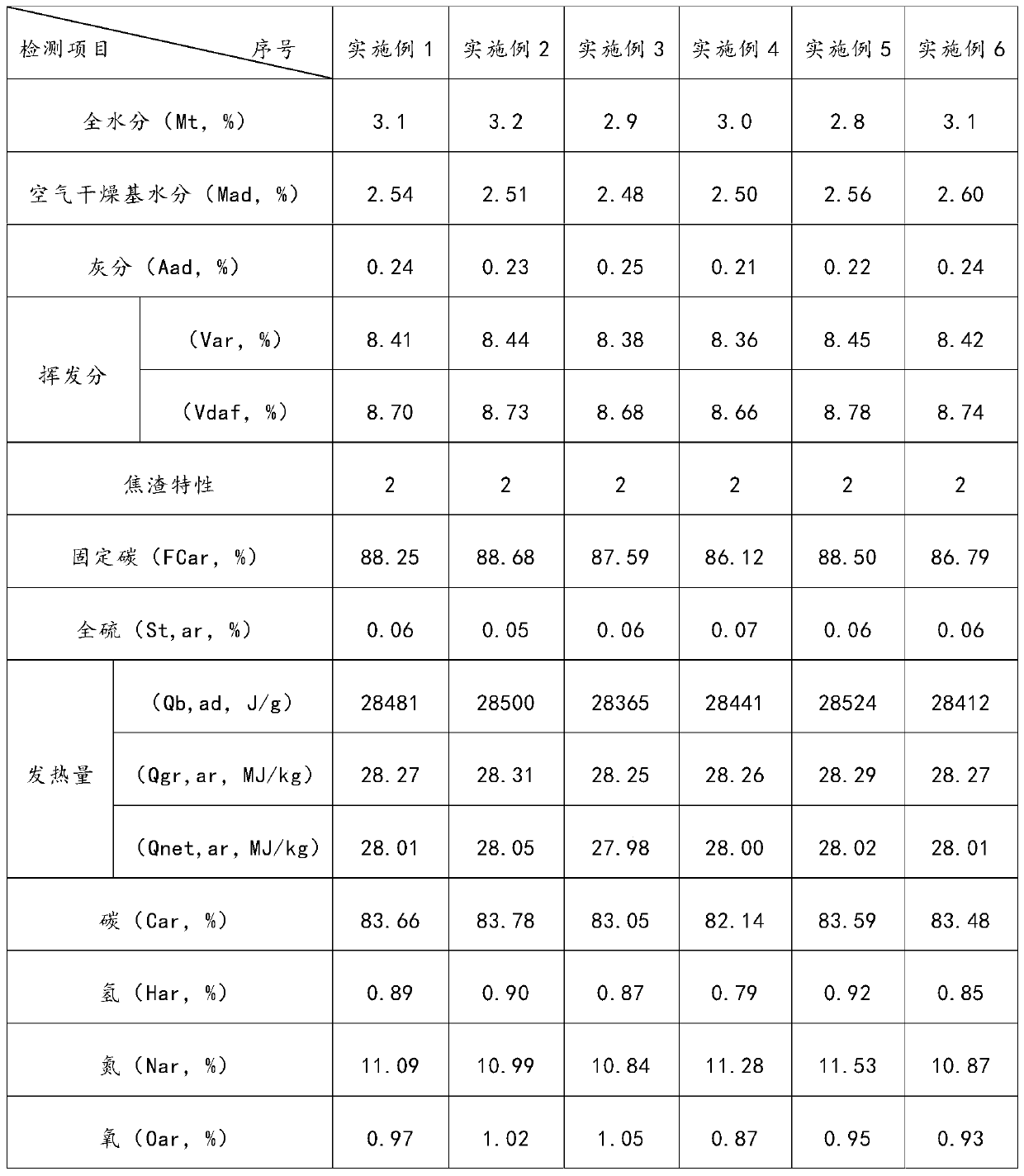

[0029] Put the still residue formed when toluene diisocyanate is synthesized by liquid phase phosgenation into a horizontal microwave pyrolysis furnace, close the furnace door, pass nitrogen and exhaust oxygen, and after reaching the anaerobic condition, open the microwave pyrolysis furnace and wait for microwave When the temperature in the pyrolysis furnace reaches 650°C, continue the normal operation of the microwave pyrolysis furnace for 3 seconds and collect the gas obtained at the same time, then close the microwave pyrolysis furnace, and when the temperature in the pyrolysis furnace drops to 200°C, open the furnace door and take out the black Product A.

Embodiment 2

[0031] Put the still residue formed when toluene diisocyanate is synthesized by liquid phase phosgenation into a vertical microwave pyrolysis furnace, close the furnace door, pass nitrogen and exhaust oxygen, and after reaching the anaerobic condition, open the microwave pyrolysis furnace and wait for microwave When the temperature in the pyrolysis furnace reaches 500°C, continue the normal operation of the microwave pyrolysis furnace for 7 seconds and collect the gas obtained at the same time, then close the microwave pyrolysis furnace, and when the temperature in the pyrolysis furnace drops to 200°C, open the furnace door and take out the black Product B.

Embodiment 3

[0033] Put the still residue formed when toluene diisocyanate is synthesized by liquid phase phosgenation into a vertical microwave pyrolysis furnace, close the furnace door, pass nitrogen and exhaust oxygen, and after reaching the anaerobic condition, open the microwave pyrolysis furnace and wait for microwave When the temperature in the pyrolysis furnace reaches 800°C, continue the normal operation of the microwave pyrolysis furnace for 3 seconds and collect the gas obtained at the same time, then close the microwave pyrolysis furnace, and when the temperature in the pyrolysis furnace drops to 150°C, open the furnace door and take out the black Product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com