Exposed-aggregate concrete and construction method thereof

A technology of exposed stone concrete and construction method, which can be applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems of unfriendly fluorosilicate environment, environmental hazards of exposed stone concrete construction, etc. The use of fluorosilicate, the effect of improving the retardation effect and the effect of improving the retardation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

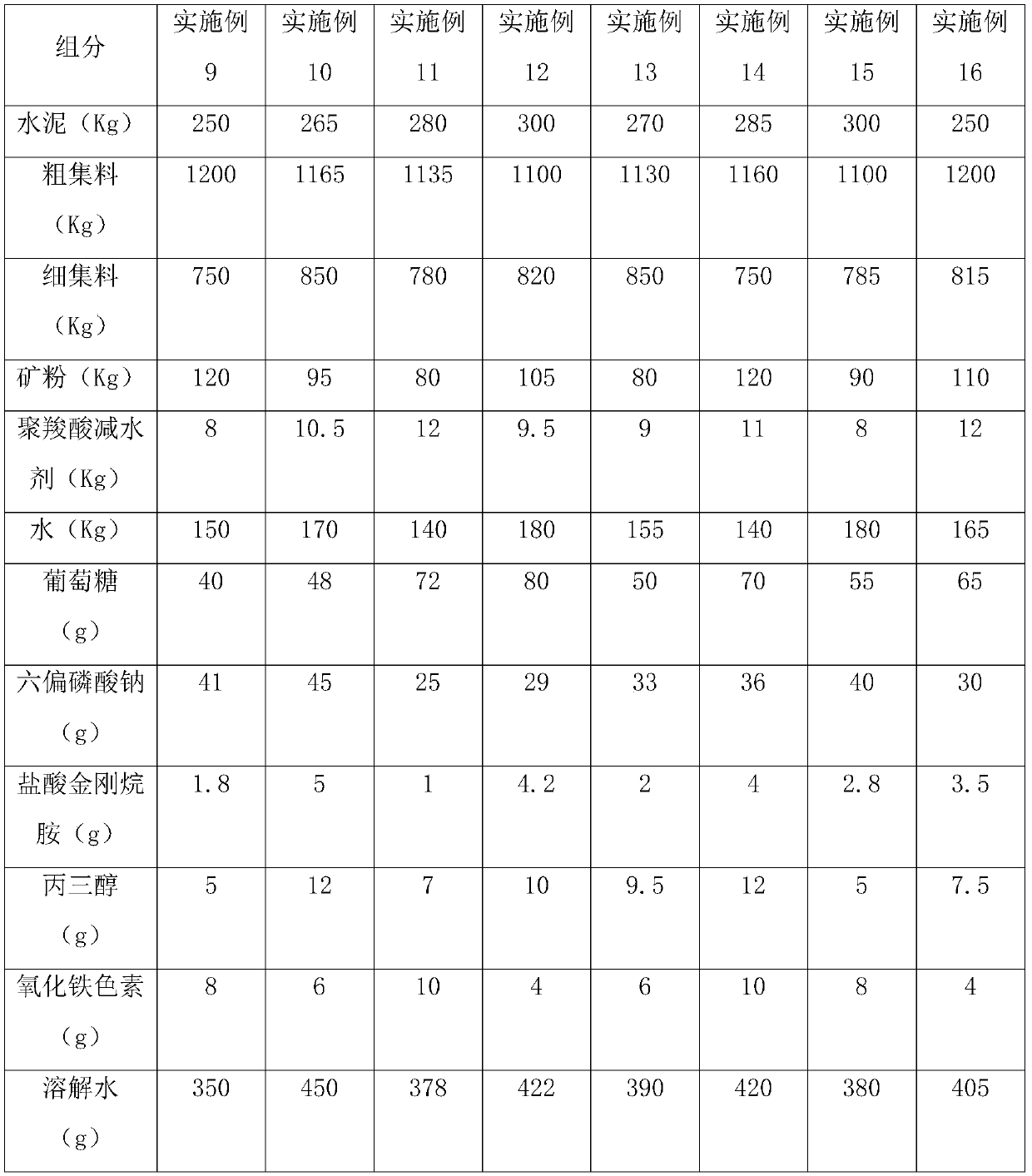

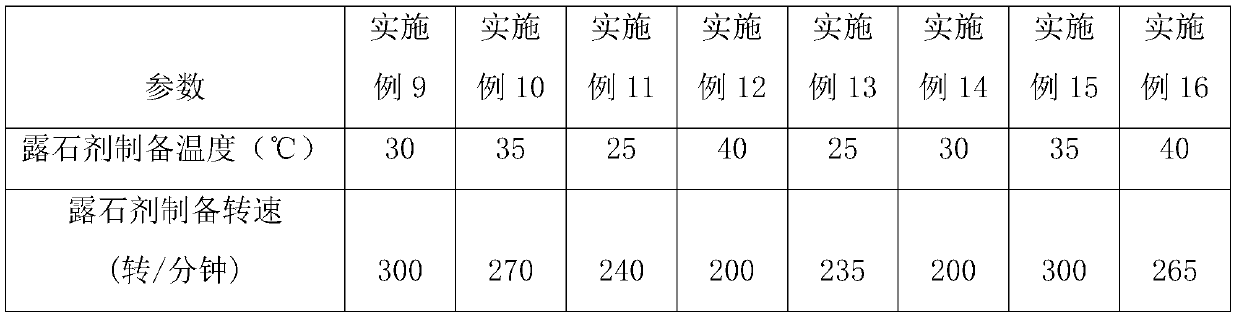

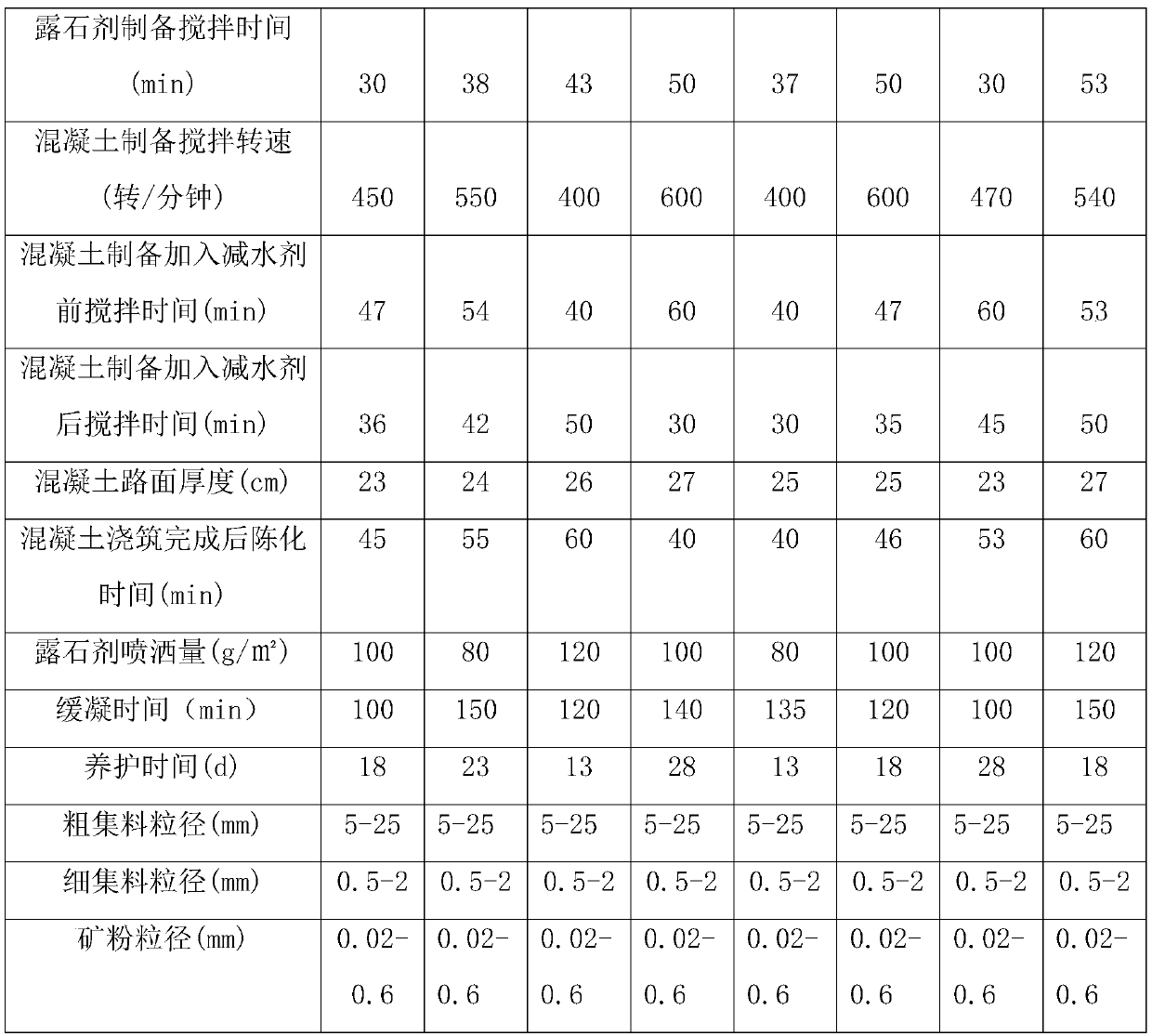

Examples

Embodiment 1

[0033] Embodiment 1: a kind of construction method of exposed stone concrete, comprises the steps:

[0034] (1) Preparation of dew stone agent: Weigh 400g of dissolved water, stir at 32°C at a speed of 250 rpm, add 60g of glucose, 35g of sodium hexametaphosphate, 3g of amantadine hydrochloride, 8.5g of glycerol and 7g of pigments The material iron oxide was stirred at a speed of 250 rpm for 40 minutes to prepare the dew stone agent;

[0035] (2) Concrete preparation: Weigh 160Kg of water and add 1150Kg of coarse aggregate, 800Kg of fine aggregate, 100Kg of mineral powder and 275Kg of cement under the condition of stirring at a speed of 500 rpm. The particle size of the coarse aggregate is 5mm-25mm , the particle size of the fine aggregate is 0.5mm-2mm, the particle size of the mineral powder is 0.02mm-0.6mm, continue to stir for 50min, add 10Kg polycarboxylate water reducer, continue to stir for 40min to obtain concrete;

[0036] (3) Pavement pouring: pour the concrete prepar...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that Example 2 uses lignosulfonate water reducer instead of polycarboxylate water reducer, and the others are consistent with Example 1.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is that embodiment 3 uses a coarse aggregate of 5mm-40mm, and the others are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com