Corrosion inhibition and coagulation inhibition synergistic cement water reducing agent and preparation method thereof

A water-reducing agent and setting retarding technology, which is applied in the field of corrosion-inhibiting and setting-inhibiting synergistic cement water-reducing agent and its preparation field, can solve the problems of limiting the application range of the water-reducing agent, failing to make full use of it, and increasing the amount of bleeding water. Achieve outstanding retardation effect, excellent dispersion performance, and reduce bleeding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

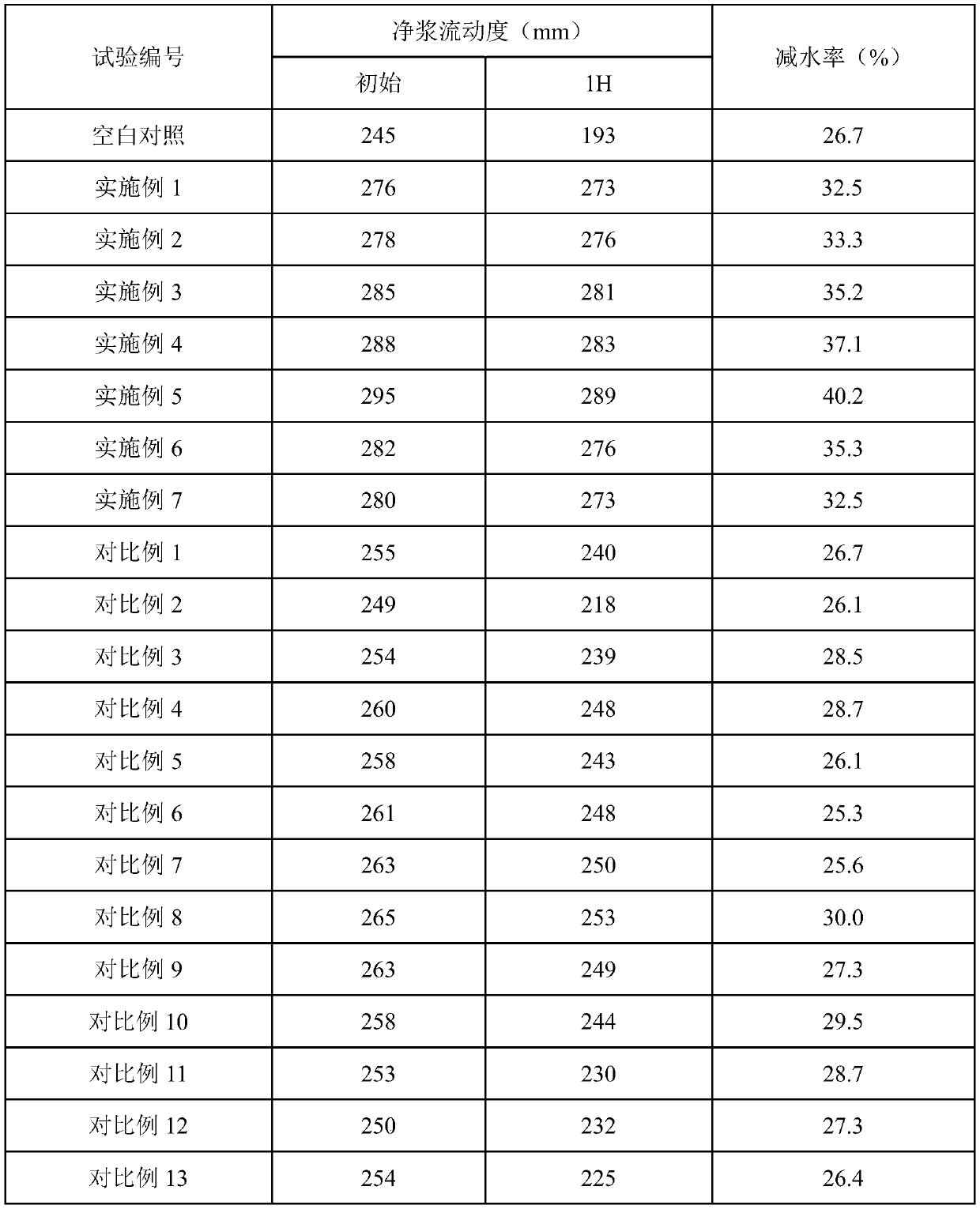

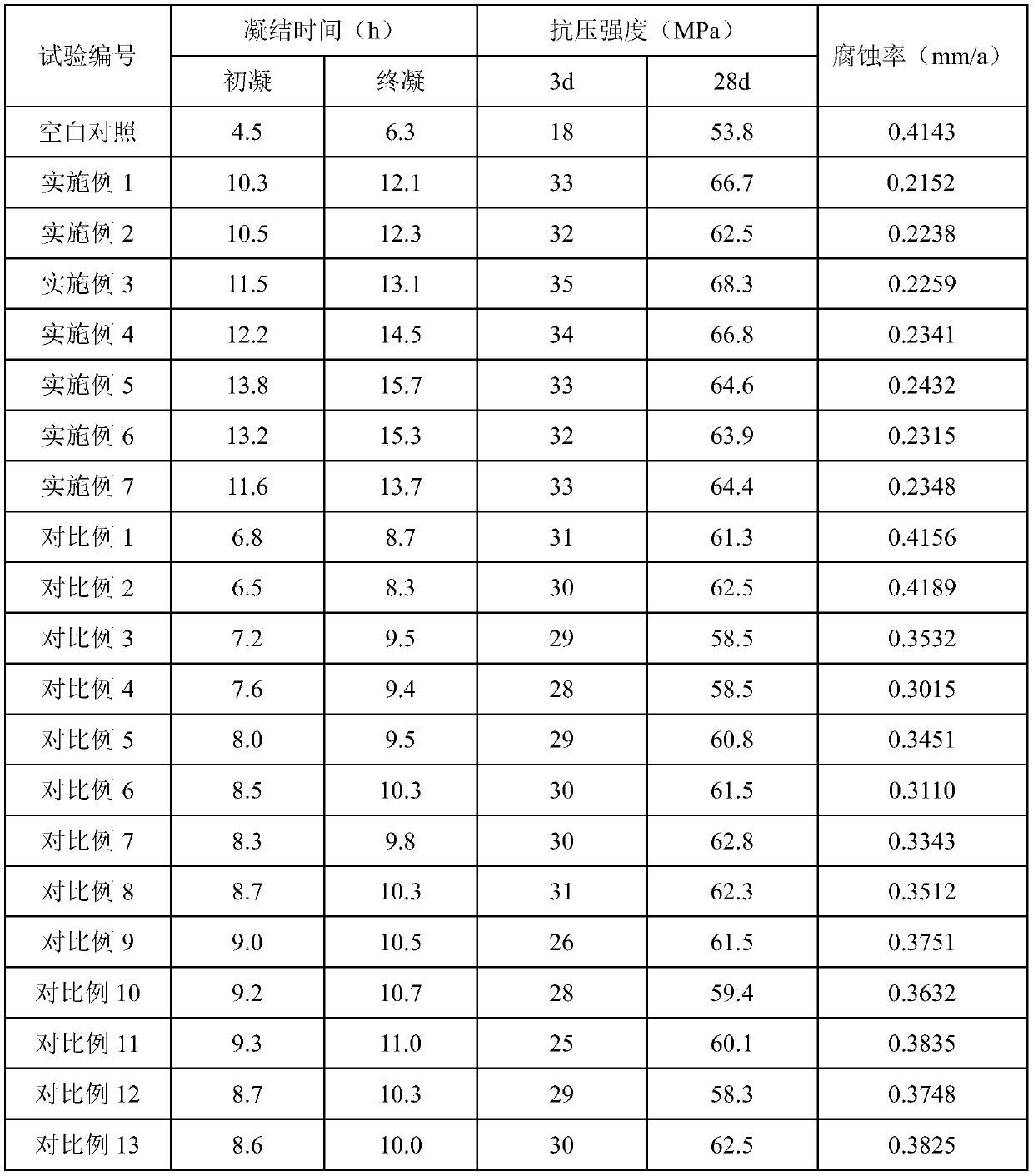

Examples

Embodiment 1

[0019] Weigh respectively 45 parts of ether type polycarboxylate superplasticizer mother liquor (40%), 0.8 part of hydroxyethylidene diphosphonic acid (60%), 16.4 parts of polyacrylic acid (PAA) dispersant (30%), solid sodium gluconate 8.3 servings. Wherein sodium gluconate is dissolved in an equal amount of water. Add the ether-type polycarboxylate superplasticizer mother liquor into the stirring tank, stir, and then add polyacrylic acid (PAA) dispersant (30%), hydroxyethylidene diphosphonic acid (60%), and sodium gluconate solution and stir to obtain a mixed solution . Slowly add 7.0 parts of 30% sodium hydroxide solution to the mixed solution to control the pH between 6-7. Add 14.2 parts of water to the mixed liquid, stir evenly, and obtain a cement water reducer.

Embodiment 2

[0021] Weigh respectively 45 parts of ether-type polycarboxylate superplasticizer mother liquor (40%), 0.8 parts of hydroxyethylidene diphosphonic acid (60%), 18.3 parts of sodium polyacrylate (PAAS) dispersant (30%), solid gluconic acid Sodium 8.3 parts. Wherein sodium gluconate is dissolved in an equal amount of water. Add the ether-type polycarboxylate superplasticizer mother liquor into the stirring tank, stir, add polyacrylic acid sodium (PAAS) dispersant (30%), hydroxyethylidene diphosphonic acid (60%), and sodium gluconate solution in turn and stir to obtain a mixed liquid. Slowly add 3.1 parts of 30% sodium hydroxide solution to the mixed solution to control the pH between 6-7. Add 16.2 parts of water to the mixed liquid, stir evenly, and obtain a cement water reducer.

Embodiment 3

[0023] Weigh 45 parts of ether-type polycarboxylate superplasticizer mother liquor (40%), 0.8 parts of hydroxyethylidene diphosphonic acid (60%), 16.4 parts of hydrolyzed polymaleic anhydride (HPMA) dispersant (30%), solid Sodium gluconate 8.3 parts. Wherein sodium gluconate is dissolved in an equal amount of water. Add the ether-type polycarboxylate superplasticizer mother liquor into the stirring tank, stir, and then add the hydrolyzed polymaleic anhydride (HPMA) dispersant (30%), hydroxyethylidene diphosphonic acid (60%), and sodium gluconate solution and stir, to obtain a mixture. Slowly add 6.1 parts of 30% sodium hydroxide solution to the mixed solution to control the pH=6-7. Add 15.1 parts of water to the mixed solution, and stir evenly to obtain a cement water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com