Rare and precious metal separation device and method

A technology for rare and precious metals and separation devices, applied in the direction of improving process efficiency, can solve problems such as improper treatment, low recovery value, secondary environmental pollution, etc., and achieve the effect of reducing the degree of pollution, improving purity, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

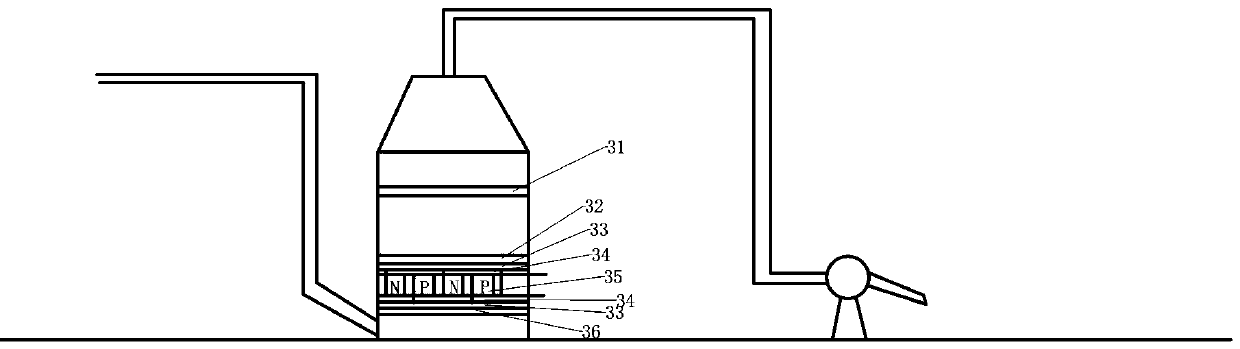

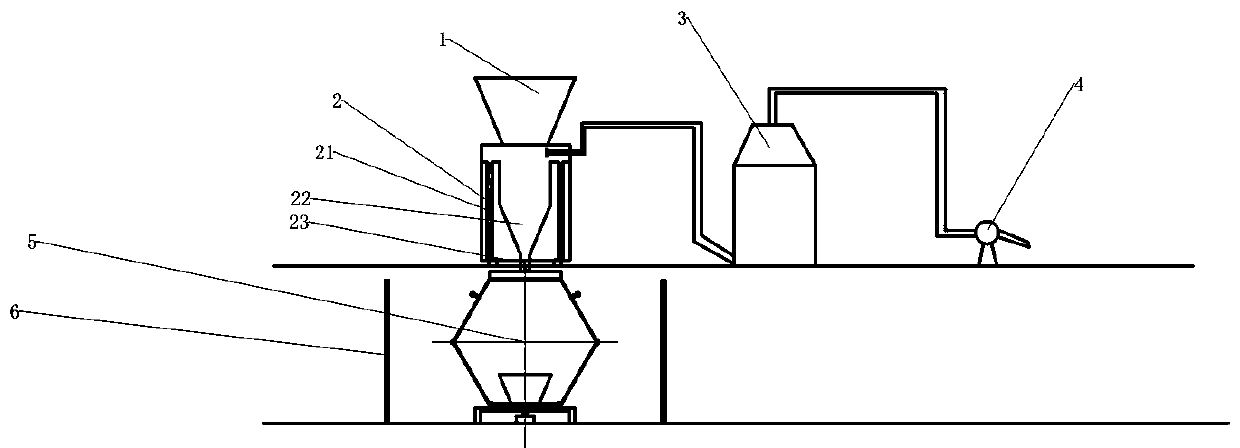

[0019] EXAMPLES Example 1, the metal to be separated this time is precious metal gold, and precious metal gold Au is recovered from electronic waste, especially circuit boards. This equipment includes hopper 1, high temperature furnace 2, gas purification furnace 3, exhaust fan 4, rotary furnace 5, and electrode plate 6, among which, hopper 1, high temperature furnace 2, gas purification furnace 3, exhaust fan 4, etc. are set in the factory building On the second floor, the rotary furnace 5 and the electrode plate 6 are set on the first floor of the factory building. The lower end of the hopper 1 is connected to the high-temperature furnace 2, the upper end of the high-temperature furnace 2 is connected to the gas purification furnace through a pipeline, and the lower end of the high-temperature furnace 2 is connected to the top of the rotary furnace 5. , The electrode plates 6 are arranged on both sides of the rotary furnace 5 .

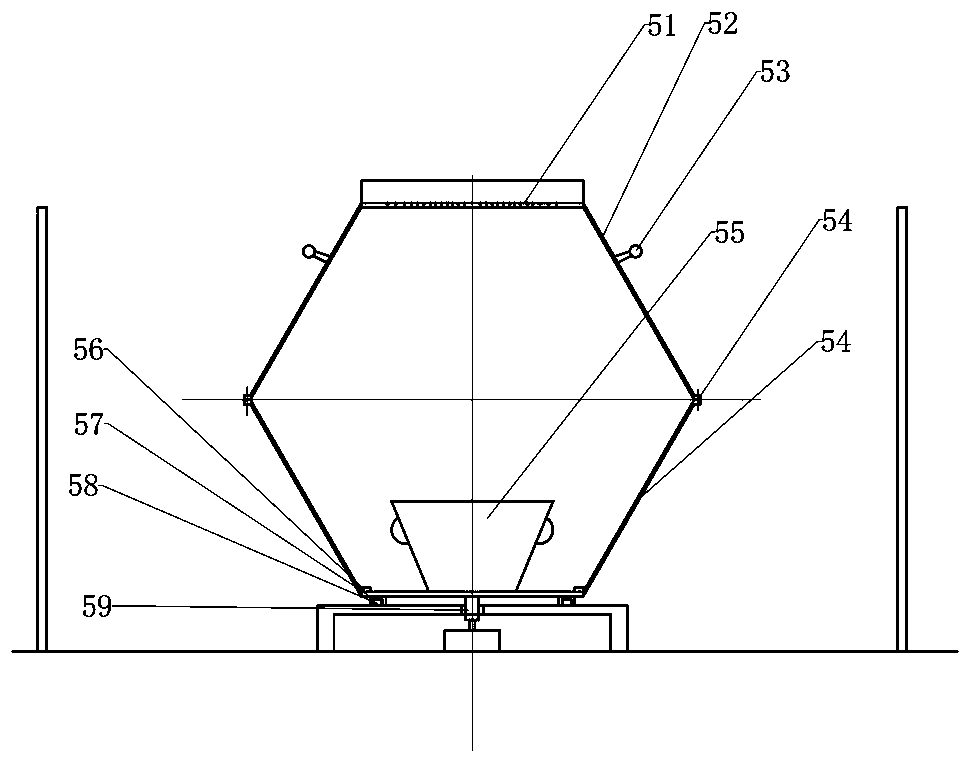

[0020] The rotary furnace 5 of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com