High-strength-plasticity antibacterial high-entropy alloy and preparation method thereof

A high-entropy alloy and plasticity technology, applied in the field of metal materials, can solve the problems of unfavorable processing technology, difficulty in concentration, and limitation of the development of antibacterial metal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

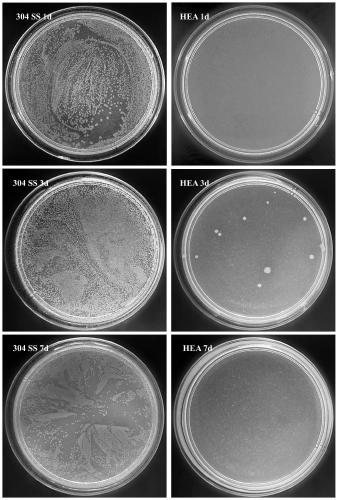

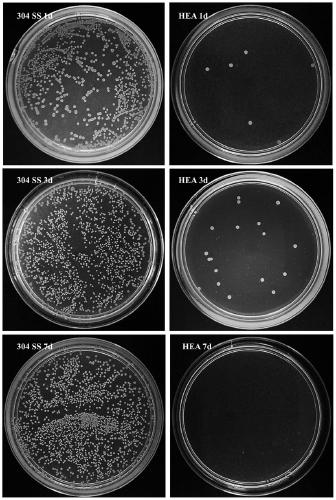

Examples

Embodiment 1

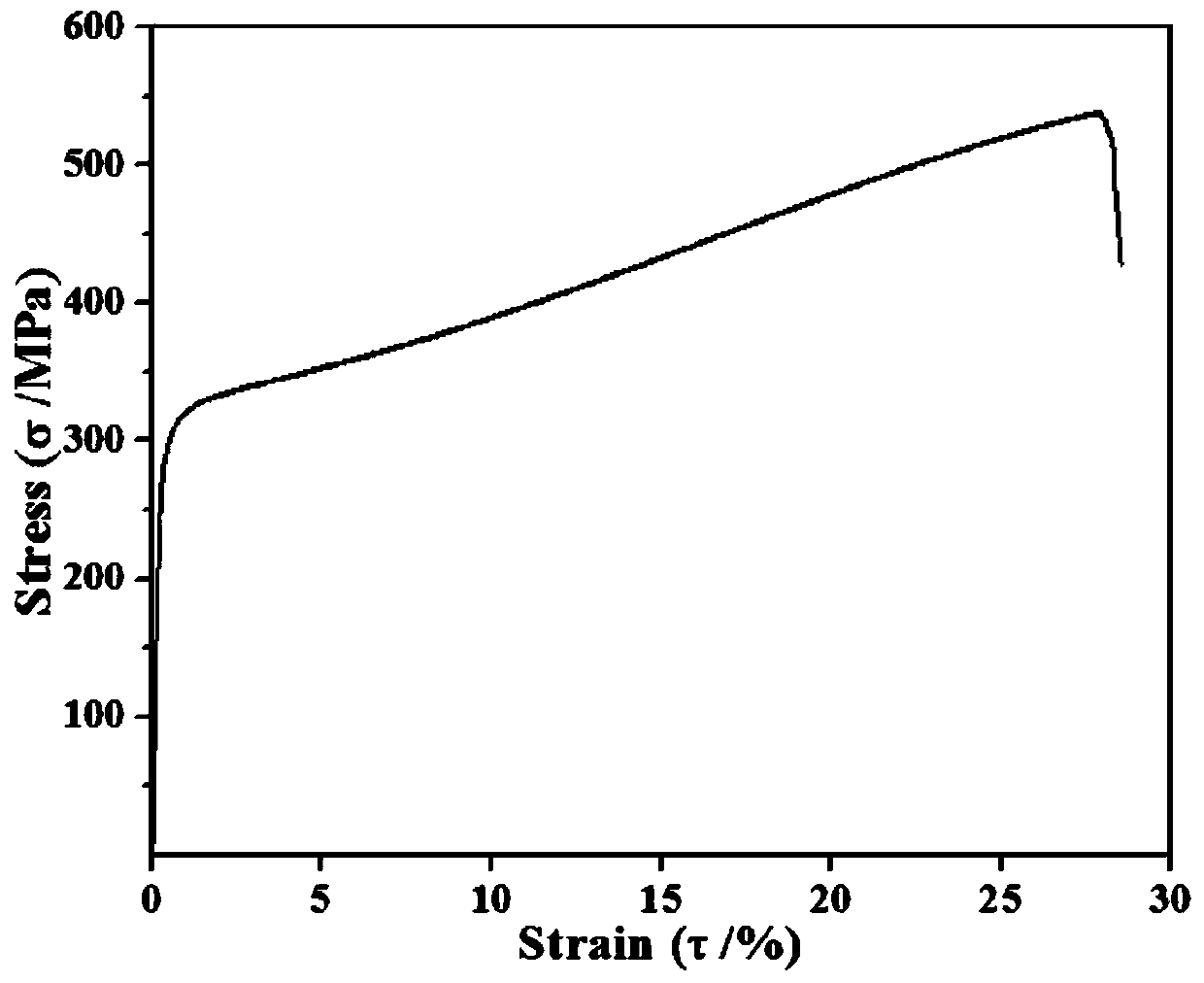

[0048] A high-strength plastic antibacterial high-entropy alloy Al 0.4 CoCrCu 1.0 FeNi, the ratio of each element is molar ratio.

[0049] The preparation method of the high-strength plastic antibacterial high-entropy alloy comprises the following steps:

[0050] (1) According to the alloy composition Al 0.4 CoCrCu 1.0 FeNi, raw materials, wherein, the ratio of each element in the alloy is a molar ratio;

[0051] (2) After the vacuum electric arc furnace is adjusted to an oxygen-free atmosphere, smelting is carried out. Specifically, Al, Co, Cr, Cu, Fe and Ni raw materials are sequentially added to the electric arc furnace, and the Al raw materials are guaranteed to be below, and Co, Cr, Cu, Fe and Ni raw materials are evenly mixed on top, and the electric arc furnace is evacuated to a vacuum degree of 3×10 -3 After Pa, argon gas is introduced into the furnace, and the argon gas pressure is 0.05 Pa. Melting is carried out. The melting time is 12 minutes to obtain alloy li...

Embodiment 2

[0058] A High Strength and Plasticity Antibacterial High Entropy Alloy CoCrCu 0.1 FeNi, the ratio of each element is molar ratio.

[0059] The preparation method of the high-strength plastic antibacterial high-entropy alloy comprises the following steps:

[0060] (1) According to the alloy composition CoCrCu 0.1 FeNi, raw materials, wherein, the ratio of each element in the alloy is a molar ratio;

[0061] (2) After the vacuum electric arc furnace is adjusted to an oxygen-free atmosphere, smelting is carried out. Specifically, Al, Co, Cr, Cu, Fe and Ni raw materials are sequentially added to the electric arc furnace, and the Al raw materials are guaranteed to be below, and Co, Cr, Cu, Fe and Ni raw materials are evenly mixed on top, and the electric arc furnace is evacuated to a vacuum degree of 1×10 -3 After Pa, argon gas is introduced into the furnace, and the argon gas pressure is 0.02 Pa. Melting is carried out. The melting time is 12 minutes to obtain alloy liquid, whi...

Embodiment 3

[0065] A High Strength and Plasticity Antibacterial High Entropy Alloy CoCrCu 1.0 FeNi, the ratio of each element is molar ratio.

[0066] The preparation method of the high-strength plastic antibacterial high-entropy alloy comprises the following steps:

[0067] (1) According to the alloy composition CoCrCu 1.0 FeNi, raw materials, wherein, the ratio of each element in the alloy is a molar ratio;

[0068] (2) After the vacuum electric arc furnace is adjusted to an oxygen-free atmosphere, smelting is carried out. Specifically, Al, Co, Cr, Cu, Fe and Ni raw materials are sequentially added to the electric arc furnace, and the Al raw materials are guaranteed to be below, and Co, Cr, Cu, Fe and Ni raw materials are evenly mixed on top, and the electric arc furnace is evacuated to a vacuum degree of 3×10 -3 After Pa, argon gas is introduced into the furnace, and the argon gas pressure is 0.05 Pa. Melting is carried out. The melting time is 12 minutes to obtain alloy liquid, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com