Aromatic antibacterial microcapsule with carbon skeleton and preparation method thereof

A carbon skeleton and microcapsule technology, applied in the field of microcapsule preparation, can solve the problems of high sealing performance of autoclave, long experiment period and high cost, and achieve the effects of improving the slow-release performance of fragrance, preventing shedding loss and improving mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

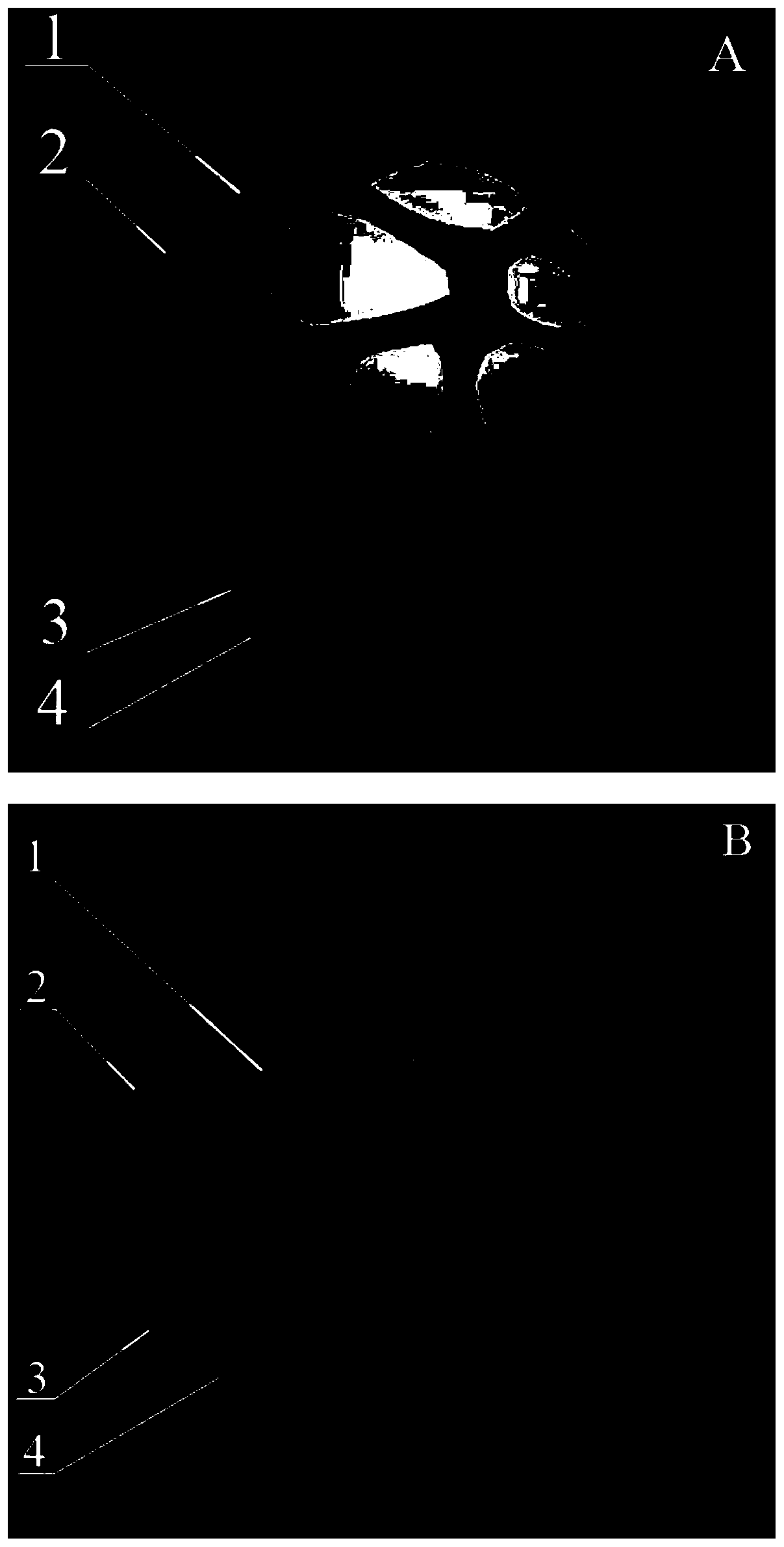

Image

Examples

Embodiment 1

[0046](1) Take 10g of lily pollen, soak it in 400mL of methanol and water mixed solution with a volume ratio of 3:1 for 2h, and dry it under vacuum at 80°C, then calcinate the dried pollen grains in a nitrogen atmosphere at 400°C 2h, making hollow carbon skeleton particles;

[0047] (2) Take 190 μL of 0.1mol / L AgNO 3 The solution, 10mL of water and 15mL of orientalis extract were added to the conical flask, and 0.1g of the carbon skeleton particles in (1) was added. Under the condition of 90°C oil bath, the reaction was stirred by magnetic force for 2h, suction filtered, and dried at 80°C for 12h , to make silver-loaded hollow carbon skeleton particles;

[0048] (3) Take 1g of gelatin, add 100mL of deionized water, and fully dissolve it in a water bath at 40°C; take another 1g of gum arabic, add 100mL of deionized water, and fully dissolve it under the same conditions;

[0049] (4) Take 6g of rose essence, add 0.1g of silver-loaded hollow carbon skeleton particles dried in (...

Embodiment 2

[0053] (1) Take 10 g of sweet-scented osmanthus pollen, soak it in 400 mL of methanol and water mixed solution with a volume ratio of 3:1 for 2 h, and dry it under vacuum at 80 °C, then calcinate the dried pollen grains at 300 °C in a nitrogen atmosphere 3h, making hollow carbon skeleton particles;

[0054] (2) Take 380 μL of 0.1mol / L AgNO 3 The solution, 15mL of water and 20mL of orientalis extract were added to the conical flask, and 0.2g of the carbon skeleton particles in (1) was added. Under the condition of 90°C oil bath, the reaction was stirred by magnetic force for 2h, suction filtered, and dried at 80°C for 12h , to make silver-loaded hollow carbon skeleton particles;

[0055] (3) Take 1g of gelatin, add 100mL of deionized water, and fully dissolve it in a water bath at 40°C; take another 1g of gum arabic, add 100mL of deionized water, and fully dissolve it under the same conditions;

[0056] (4) Take 8g of rose essence, add 0.2g of silver-loaded hollow carbon skel...

Embodiment 3

[0060] (1) Take 10 g of morning glory pollen, soak it in 400 mL of a mixed solution of methanol and water with a volume ratio of 3:1 for 2 hours, and dry it under vacuum at 80°C, then place the dried pollen grains in a nitrogen atmosphere at 200°C Medium calcination for 4 hours to make hollow carbon skeleton particles;

[0061] (2) Take 247 μL of 0.1mol / L AgNO 3 The solution, 12mL of water and 12mL of orientalis extract were added to the conical flask, and 0.13g of the carbon skeleton particles in (1) were added. Under the condition of 90°C oil bath, the reaction was stirred by magnetic force for 2h, suction filtered, and dried at 80°C for 12h , to make silver-loaded hollow carbon skeleton particles;

[0062] (3) Take 1g of gelatin, add 100mL of deionized water, and fully dissolve it in a water bath at 40°C; take another 1g of gum arabic, add 100mL of deionized water, and fully dissolve it under the same conditions;

[0063] (4) Take 10 g of rose essence, add 0.13 g of silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com