Preparation method of nanometer preservative containing composite extracts and corrosion resistance application of nanometer preservative

A compound extract and preservative technology, applied in application, food science, food preservation, etc., can solve the problems of food quality and nutritional value, it is difficult to achieve the effect of anti-corrosion, quality preservation and sterilization, and achieve the effect of avoiding volatilization and oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

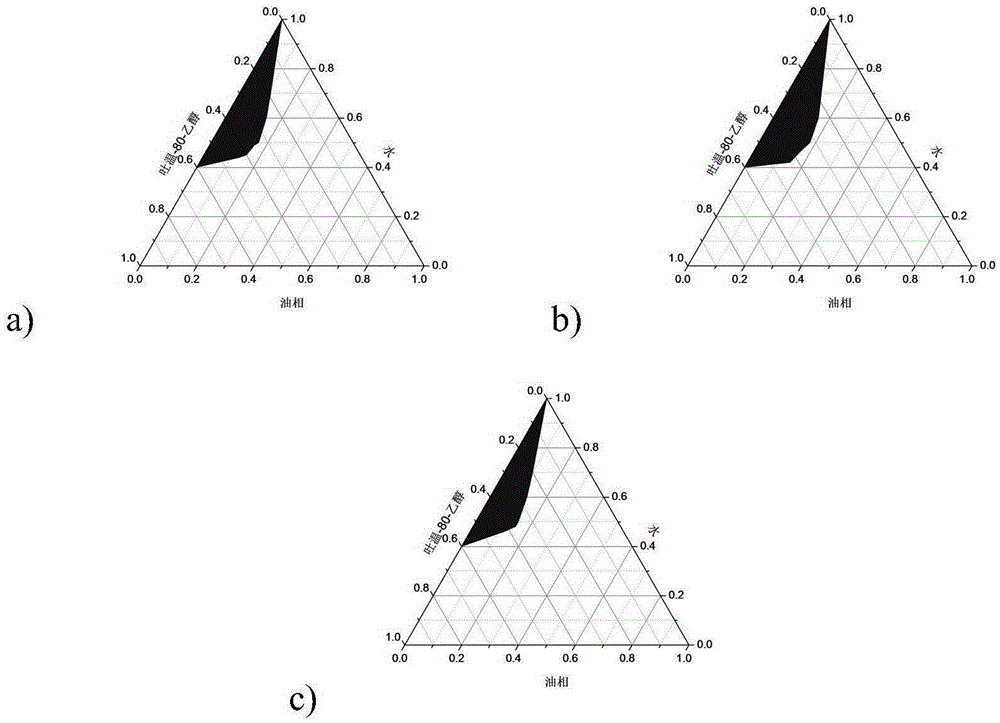

[0033] Example 1: Optimization of the preparation process of nano-composite clove / cinnamon / ginger extract

[0034] The present invention determines K by drawing a pseudo-ternary phase diagram m value, the determined surfactant Tween-80 and co-surfactant absolute ethanol are expressed in K m The values are 4:1, 3:1, 2:1, and then mixed with the determined oil phase at a mass ratio of 9:1, 8:2 to 1:9, and distilled water is added drop by drop while stirring until the oil phase is formed. For a clear and transparent emulsion, record the water content at the critical point when the system suddenly becomes thin from viscous, and use the oil phase, surfactant / co-surfactant, and water phase as the three vertices of the phase diagram to draw a pseudo-ternary phase diagram. The size of the forming milk area determines K m value. The result is as figure 1 , when K m =3:1 (Tween-80 and absolute ethanol mass fraction ratio), the area of the formed microemulsion area is the larges...

Embodiment 2

[0035] Embodiment 2: Containing the antisepsis example of composite extract nano preservative for chicken juice

[0036] Add the nano preservative containing compound clove / cinnamon / ginger extract of the present invention to the chicken juice at 0.5g / kg, mix and stir evenly, sterilize at 85°C for 15mins, and put it in a thermostat at 37°C after sterilization . Observe the sensory quality of chicken broth and determine the change of the total number of colonies every week. Compared with the chicken juice without adding the nano preservative, there was no change in the sensory quality, and the total number of colonies was significantly less, indicating that the nano preservative containing the compound clove / cinnamon / ginger extract had an inhibitory effect on the growth of microorganisms. Moreover, compared with the traditional high-temperature sterilized products, the sensory quality improved after sterilization and during storage, indicating that the antiseptic method combine...

Embodiment 3

[0037] Embodiment 3: Containing the antisepsis example of composite extract nano preservative for seasoning fresh soy sauce

[0038] Add the nano-preservative containing compound clove / cinnamon / ginger extract of the present invention to seasoning fresh soy sauce at 0.5g / kg, mix and stir evenly, sterilize at 85°C for 20mins, and put it in a thermostat at 37°C after sterilization middle. Observe the sensory quality of seasoning fresh soy sauce and determine the change of the total number of colonies every week. Compared with the seasoning fresh soy sauce without adding the nano preservative, the sensory quality did not change, and the total number of colonies was significantly less, indicating that the nano preservative containing the compound clove / cinnamon / ginger extract had an inhibitory effect on the growth of microorganisms. Moreover, compared with the traditional high-temperature sterilized products, the sensory quality improved after sterilization and during storage, ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com