Preparation of antimicrobial nanofiber complex film with biological activity and application thereof

A nanofiber and biologically active technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of difficult action of lysozyme and unsatisfactory antibacterial effect, and achieve good toughness, low toxicity, and low toxicity biocompatibility Sexuality and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 6g of polyvinyl alcohol and dissolve it in 100mL of distilled water, and magnetically stir for 4 hours at a temperature of 80°C to obtain a polyvinyl alcohol solution;

[0029] (2) After the polyvinyl alcohol solution obtained in step (1) is cooled to room temperature, add egg white lysozyme (purchased from American Amresco Company) in a proportion of 2% of the mass of the polyvinyl alcohol solution, and add EDTA at the same time; stir magnetically at room temperature for 1 h , to obtain a spinning solution; the concentration of the EDTA in the spinning solution is 4mmol / L;

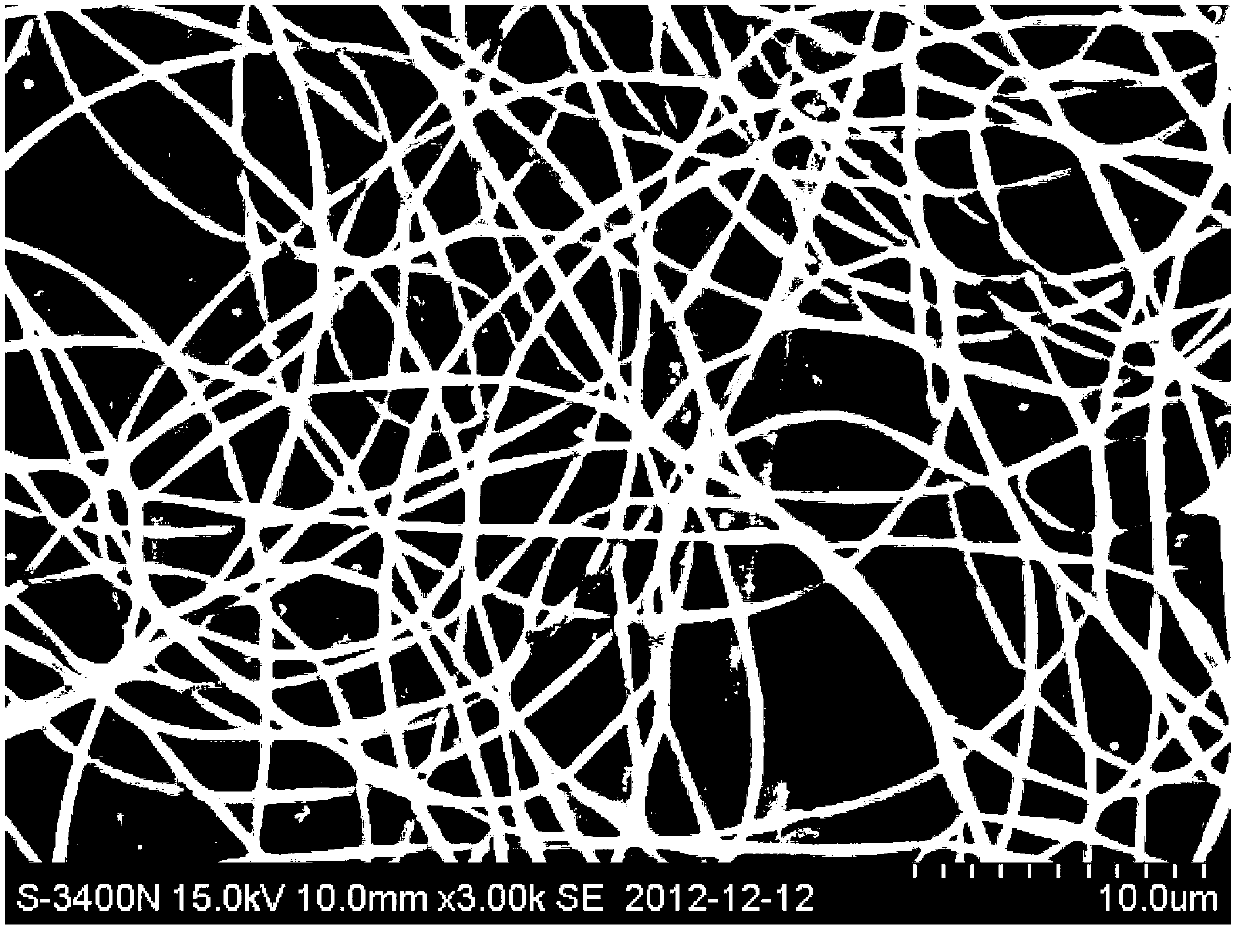

[0030] (3) Inhale the spinning solution obtained in step (2) into a 20mL syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 18cm, adjust the voltage at 15kV, and control the flow rate of the spinning solution at 0.19mL / h. silk for 4 hours, and then vacuum-dried at 45°C for 2 hours to obtain a 6%PVA+2%Lysozyme+4mmol / LEDTA nanofiber co...

Embodiment 2

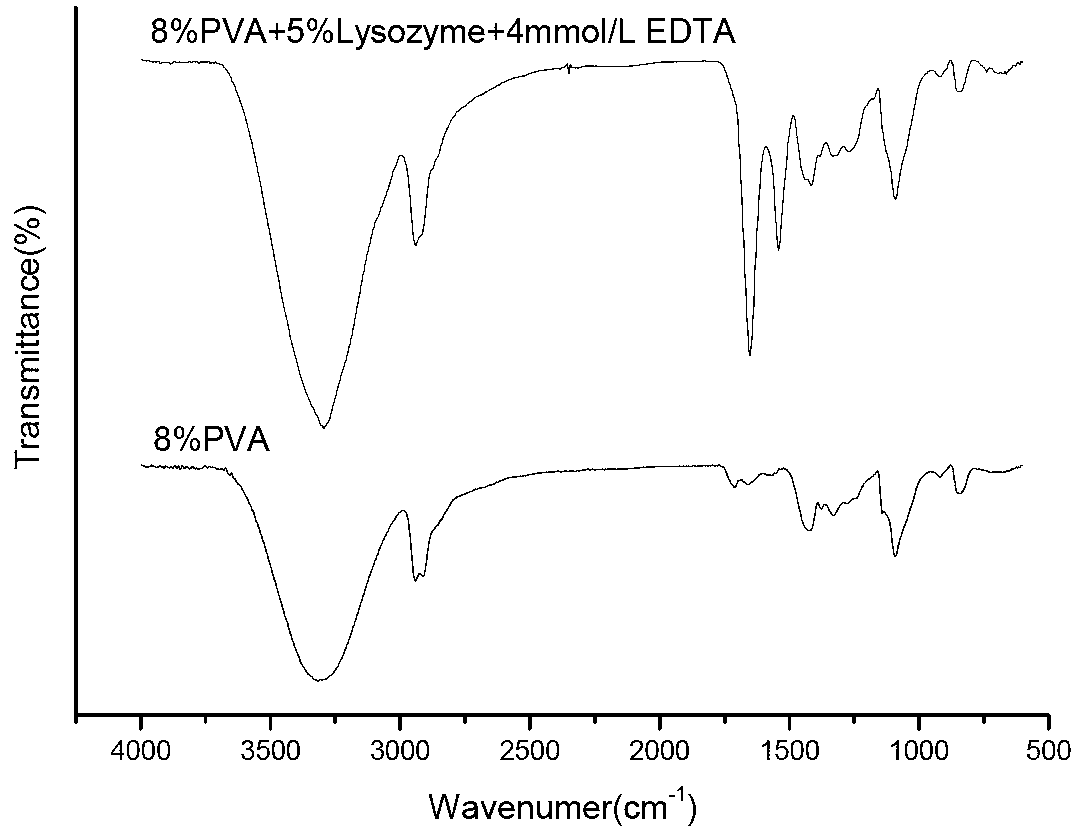

[0032] (1) Weigh 8g of polyvinyl alcohol and dissolve it in 100mL of distilled water, and magnetically stir for 4 hours at a temperature of 80°C to obtain a polyvinyl alcohol solution;

[0033] (2) After the polyvinyl alcohol solution obtained in step (1) is cooled to room temperature, add egg white lysozyme (purchased from American Amresco Company) in a proportion of 5% of the mass of the polyvinyl alcohol solution, and add EDTA at the same time; stir magnetically at room temperature for 1 h , to obtain a spinning solution; the concentration of the EDTA in the spinning solution is 4mmol / L;

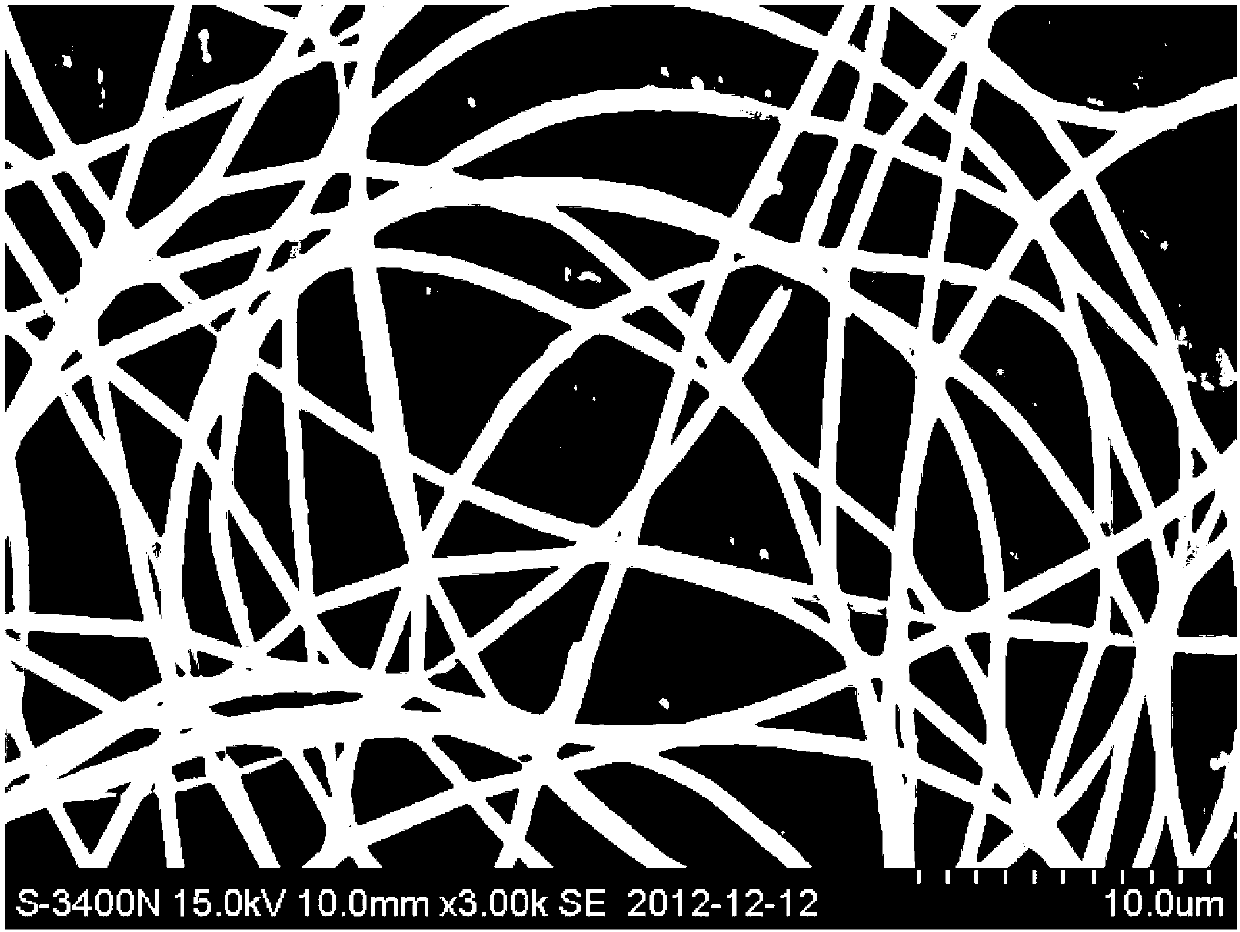

[0034] (3) Inhale the spinning solution obtained in step (2) into a 20mL syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 12cm, adjust the voltage at 15kV, and control the flow rate of the spinning solution at 0.17mL / h. Spinning for 4 hours, and then vacuum drying at 45°C for 2 hours to obtain 8%PVA+5%Lysozyme+4mmol / LEDTA nanofiber...

Embodiment 3

[0036] (1) Weigh 6g of polyvinyl alcohol and dissolve it in 100mL of distilled water, and magnetically stir for 4 hours at a temperature of 80°C to obtain a polyvinyl alcohol solution;

[0037] (2) After the polyvinyl alcohol solution obtained in step (1) is cooled to room temperature, add egg white lysozyme (purchased from American Amresco Company) in a proportion of 2% of the mass of the polyvinyl alcohol solution, and add EDTA at the same time; stir magnetically at room temperature for 1 h , to obtain a spinning solution; the concentration of the EDTA in the spinning solution is 6mmol / L;

[0038] (3) Inhale the spinning solution obtained in step (2) into a 20mL syringe, install a needle with a diameter of 0.8mm, adjust the distance from the needle to the receiver to 18cm, adjust the voltage at 15kV, and control the flow rate of the spinning solution at 0.18mL / h. Spinning for 4 hours, and then vacuum drying at 50°C for 2 hours to obtain 8%PVA / 2%Lysozyme / 6mmolEDTA nanofiber c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com