Sputtering Apparatus and Method for Controlling Sputtering Apparatus

A technology of a sputtering device and a control method, applied in the directions of sputtering coating, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of reduced film uniformity, reduced target service life, reduced operation rate, etc. Improve the effect of increasing the total usage, prolong the service life, and increase the effect of increasing the total usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the sputtering apparatus of the present invention will be described in detail with reference to the drawings.

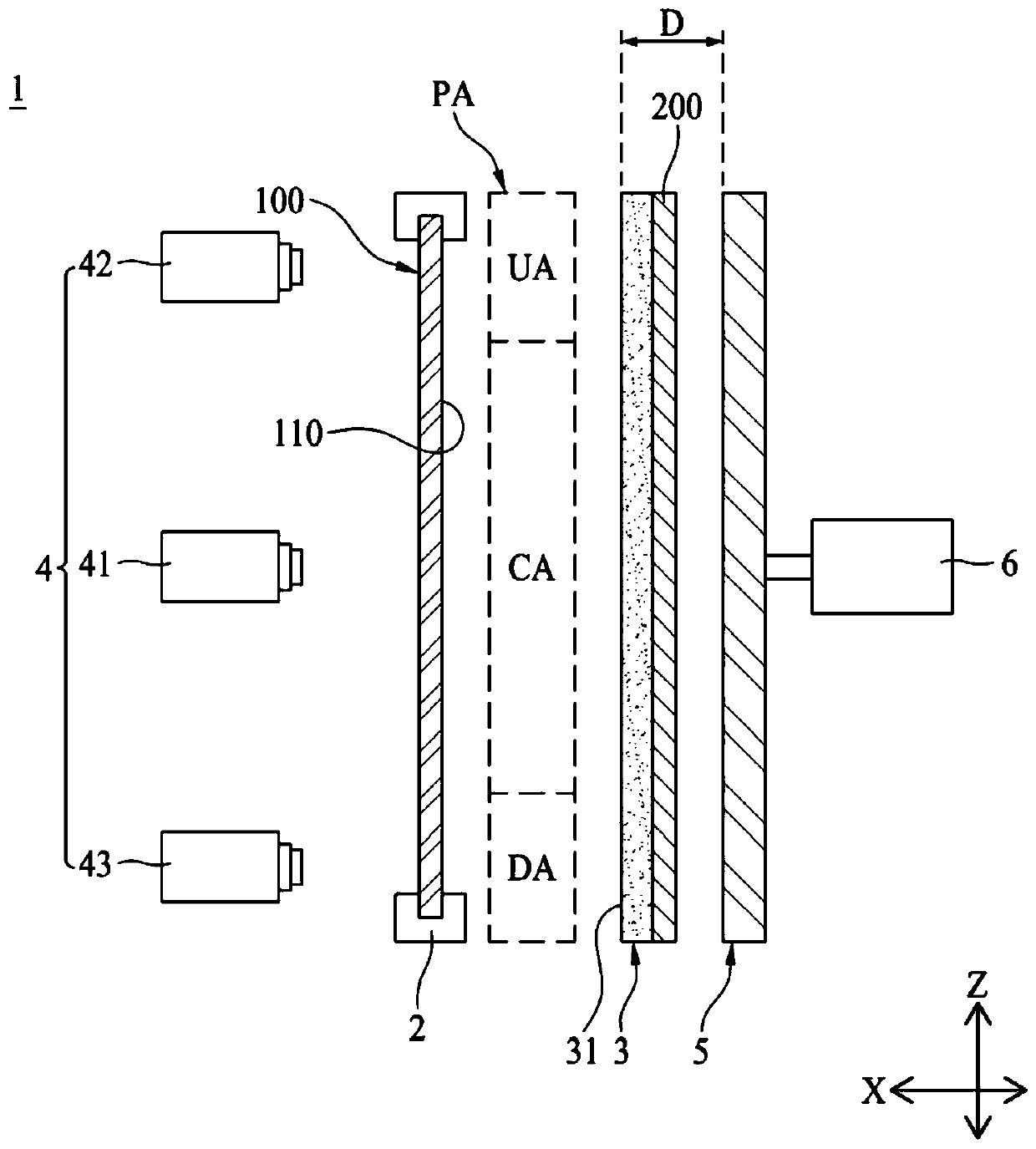

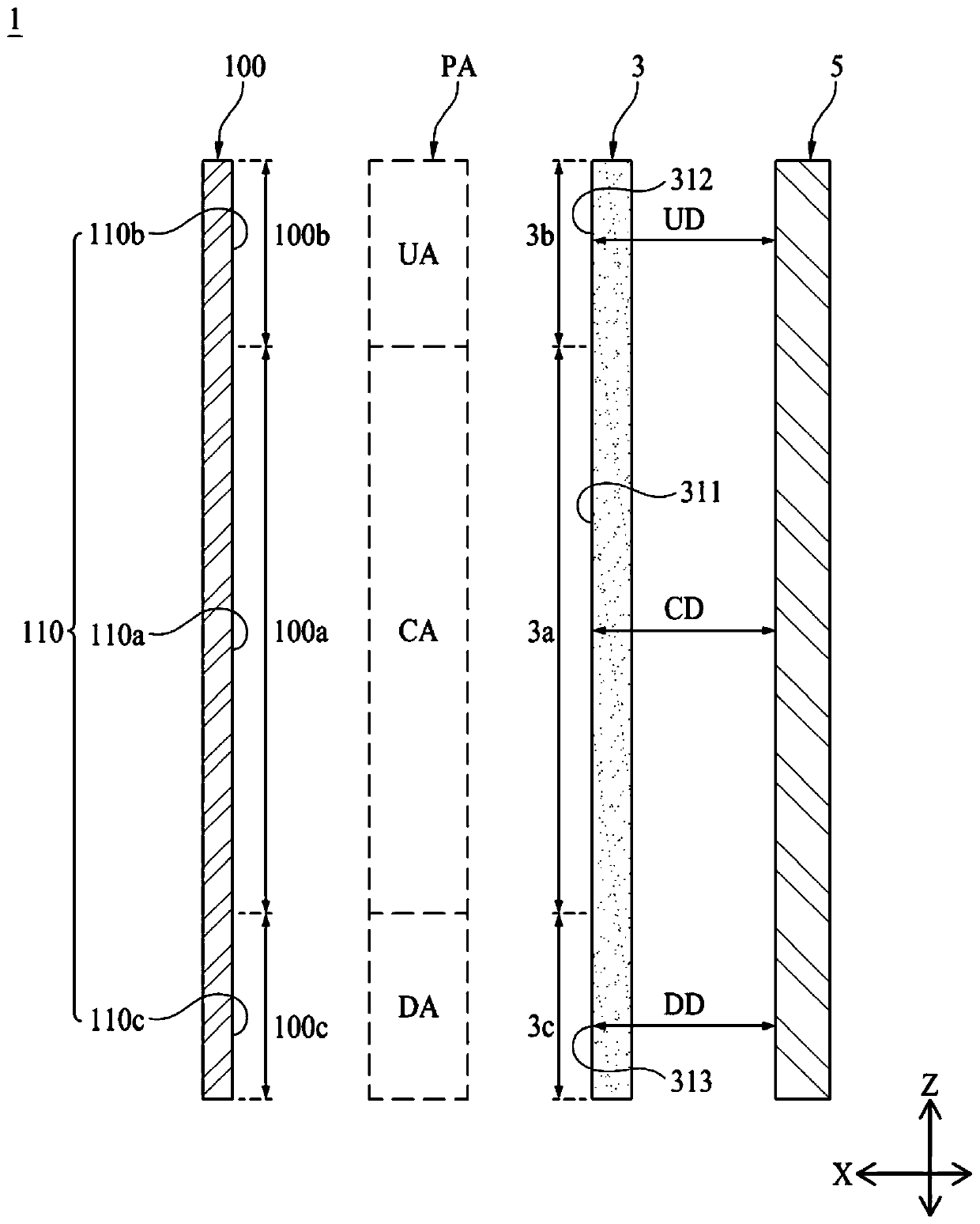

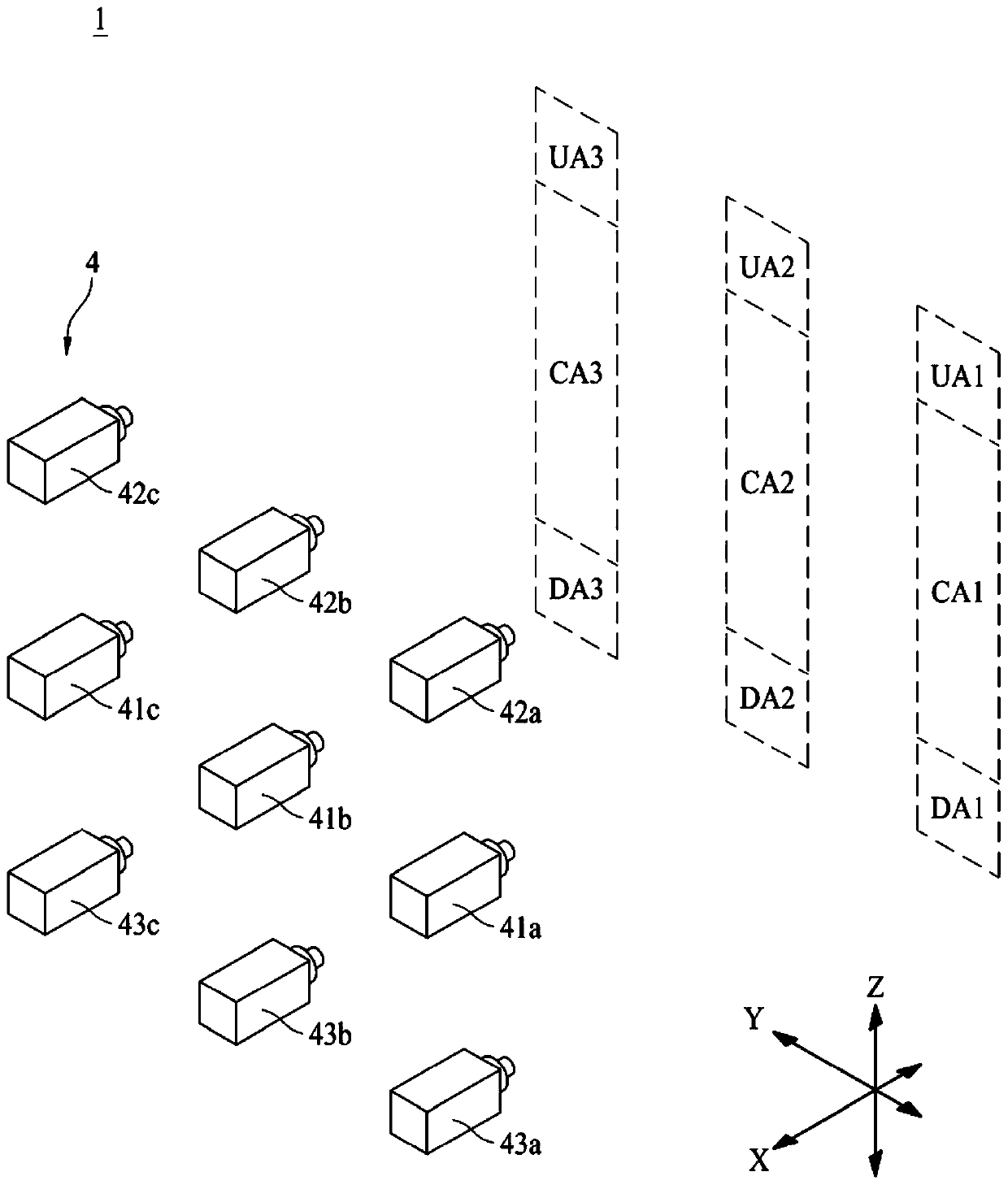

[0039] refer to figure 1 , the sputtering apparatus 1 of the present invention performs a sputtering process on a substrate 100 for manufacturing a display device, a solar cell (Solar Cell), a semiconductor device, and the like. The sputtering device 1 of the present invention includes a support unit 2 , a target 3 , an acquisition unit 4 , a magnet unit 5 , and a moving unit 6 .

[0040] refer to figure 1, the supporting part 2 is used to support the substrate 100 . The supporting part 2 can support the substrate 100 such that the substrate 100 stands parallel to the up-down direction (Z-axis direction). The supporting part 2 can respectively support the upper end of the substrate 100 and the lower end of the substrate 100 based on the vertical direction (Z-axis direction). The support unit 2 may be disposed between the acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com