Porous copper-wood fiber/polystyrene double-layer composite capillary core for loop heat pipe and preparation method thereof

A wood fiber and polystyrene technology, applied in the field of heat transfer, can solve the problem of not comprehensively considering the balance between effective evaporation and low back conduction, and achieve the effect of being beneficial to startup and operation, reducing temperature and pressure, and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a porous copper-wood fiber / polystyrene double-layer composite capillary core for a loop heat pipe, comprising the following steps:

[0030] Step 1: Take an appropriate amount of sodium chloride particles, ball mill and sieve to obtain a pore-forming agent with a particle size of 50 μm, dry and remove water for later use;

[0031] Step 2: At room temperature, mix polystyrene (PS) with a particle size of 50 μm and wood fiber (WF) with a length of 100 μm in a mass ratio of 6:4, and stir and mix at a speed of 200 rpm for 4 hours to obtain polystyrene / wood fiber mixed powder;

[0032] Step 3: At room temperature, mix the polystyrene / wood fiber mixed powder with a pore-forming agent with a particle size of 50 μm at a mass ratio of 1:3, and press the obtained PS / WF / NaCl mixture into shape by cold pressing, Obtain tablet A with a pressure of 110MPa; then mix electrolytic copper powder with a particle size of 5 μm and a pore-forming agent with a particle...

Embodiment 2

[0047] The method for preparing the porous copper-wood fiber / polystyrene double-layer composite wick for loop heat pipes in this example is basically the same as that in Example 1, except that the pore-forming agent in steps 1 to 7 is anhydrous sodium carbonate.

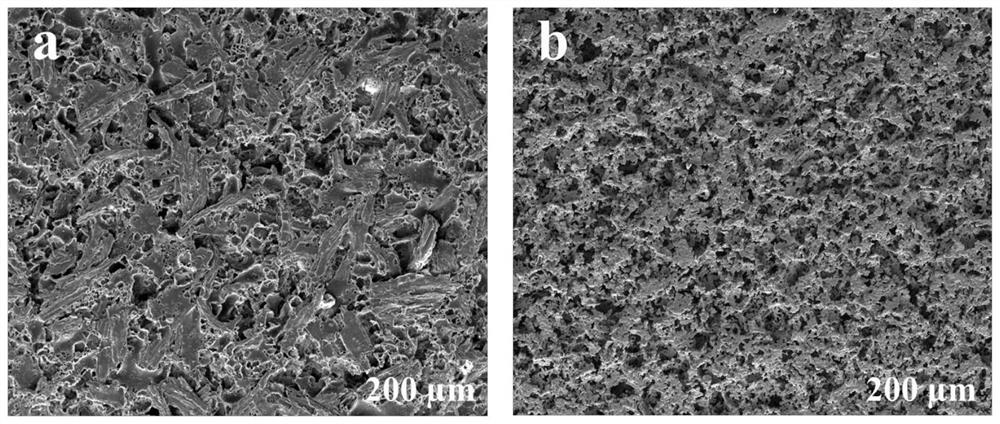

[0048] The thermal conductivity of the porous copper capillary main core obtained in this embodiment is about 27.6W / m / K, and the thermal conductivity of the additional core of wood fiber / polystyrene composite material is about 0.151W / m / K. The pore diameter is within the range of 50 μm-75 μm, and the overall porosity can be controlled within the range of 70%-80%.

Embodiment 3

[0050] The method for preparing the porous copper-wood fiber / polystyrene double-layer composite capillary core for the loop heat pipe in this embodiment is basically the same as that of Example 1, the difference is that in step 3, the mixing time of the ball mill is 3h, and the ball mill speed is 250r / min; in step 3, the compression pressure of tablet A is 115MPa, and the compression pressure of tablet B is 300MPa.

[0051] The thermal conductivity of the porous copper capillary main core obtained in this embodiment is about 29.1W / m / K, and the thermal conductivity of the additional core of wood fiber / polystyrene composite material is about 0.168W / m / K. The prepared capillary core The pore size is 50 μm, and the overall porosity can be controlled within the range of 70%-80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com