Cable type sensor for pose monitoring of coal mining machinery

A technology of coal mining machinery and sensors, which is applied in the direction of using optical devices to transmit sensing components, converting sensor outputs, and using optical devices, etc., which can solve the problems of time-consuming and labor-intensive processing, inability to move relative to each other, and low production efficiency to achieve extended use The effect of life, ease of positioning, and improvement of strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

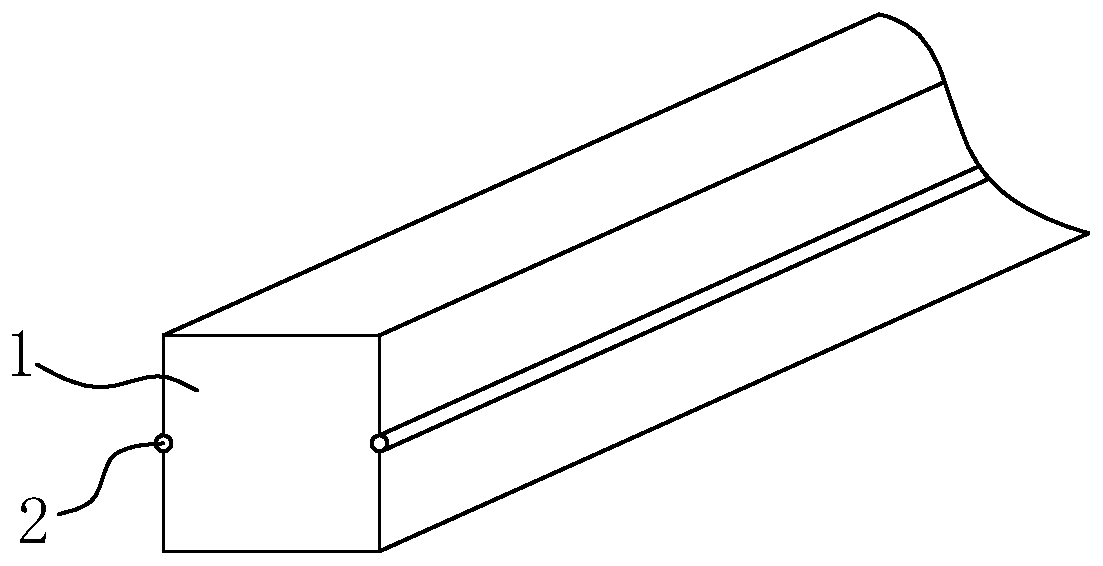

[0040] Such as figure 1 with figure 2 As shown, the cable sensor for attitude monitoring of coal mining machinery disclosed in the present invention includes a carrier 1 in the form of a cable, and the outer profile of the cross-section of the carrier 1 in the form of a cable perpendicular to its axial direction is a square and a solid body. An optical fiber 2 is respectively fixed at the center of one group of two opposing surfaces in the axial direction of the carrier 1. In this embodiment of the present invention, two optical fibers 2 are arranged in total, and the optical fibers 2 are arranged parallel to the axial direction of the carrier 1. The connecting lines of the two optical fibers 2 are respectively located on the vertical plane or the horizontal plane, so as to ensure that at least two optical fibers 2 are located on the same vertical plane, and at least two optical fibers 2 are located on the same horizontal plane.

[0041] When in use, the cable sensor provide...

Embodiment 2

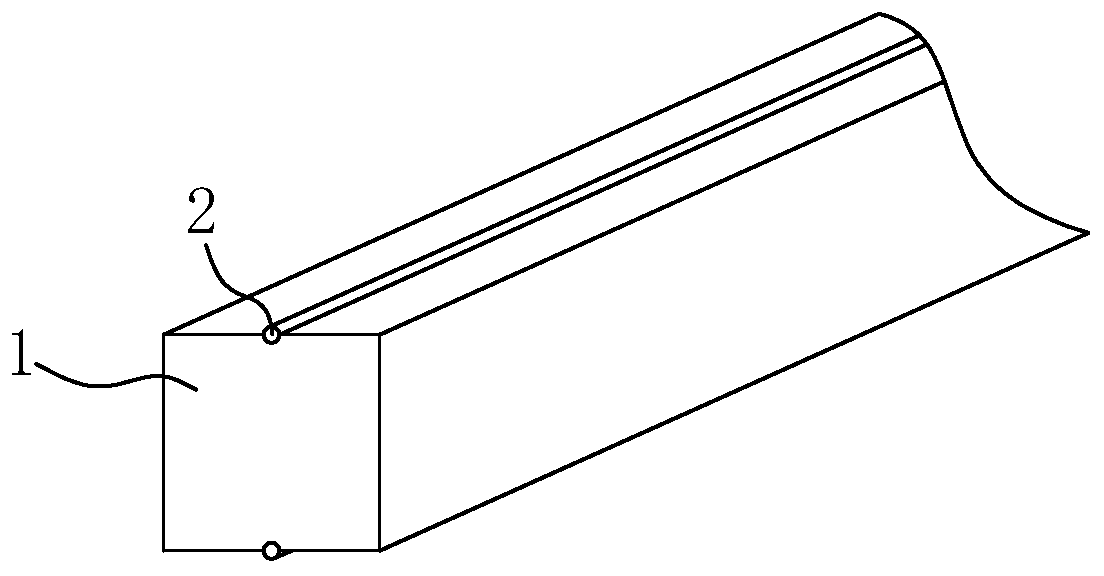

[0044] Such as image 3 and Figure 4 As shown, the cable sensor for attitude monitoring of coal mining machinery disclosed in the present invention includes a carrier 1 in the form of a cable, and the outer profile of the cross-section of the carrier 1 in the form of a cable perpendicular to its axial direction is a square and a solid body. An optical fiber 2 is respectively fixed at the center of the four faces of the carrier 1 in the axial direction. The optical fiber 2 is arranged parallel to the axial direction of the carrier 1. The four optical fibers 2 are distributed in a "ten" shape, that is, two optical fibers located on the diagonal 2 are respectively located on the vertical plane and the horizontal plane, so as to ensure that at least two optical fibers 2 are located on the same vertical plane, and at least two optical fibers 2 are located on the same horizontal plane.

[0045] When in use, the cable sensor provided by the present invention for monitoring the atti...

Embodiment 3

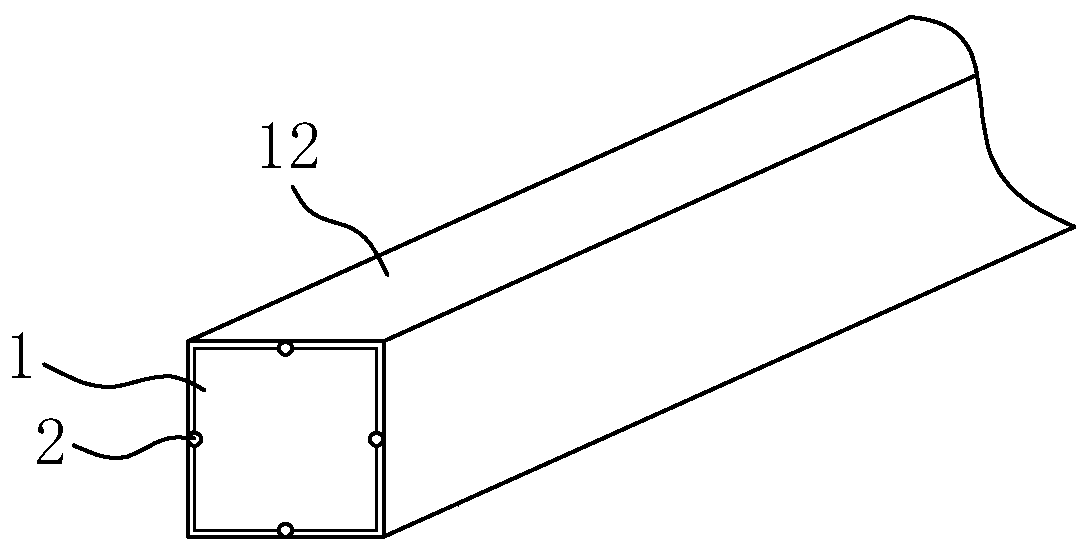

[0049] The cable sensor for monitoring the posture of coal mining machinery disclosed in the second embodiment of the present invention, such as Figure 5 As shown, its structure is basically the same as that in Example 2, the difference is that the carrier 1 is a hollow body.

[0050] The difference between embodiment 2 and embodiment 3 of the disclosed cable sensor for attitude monitoring of coal mining machinery is that the carrier 1 is set as a solid body in embodiment 2, which can strengthen the strength of carrier 1, while the hollow body in embodiment 3 The carrier 1 realizes the weight reduction of the carrier 1, saves consumables and reduces the cost at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com