Motor online fault monitoring system and analysis method thereof

A fault monitoring and monitoring unit technology, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of labor and material cost, long inspection time, and high professional level of inspection personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

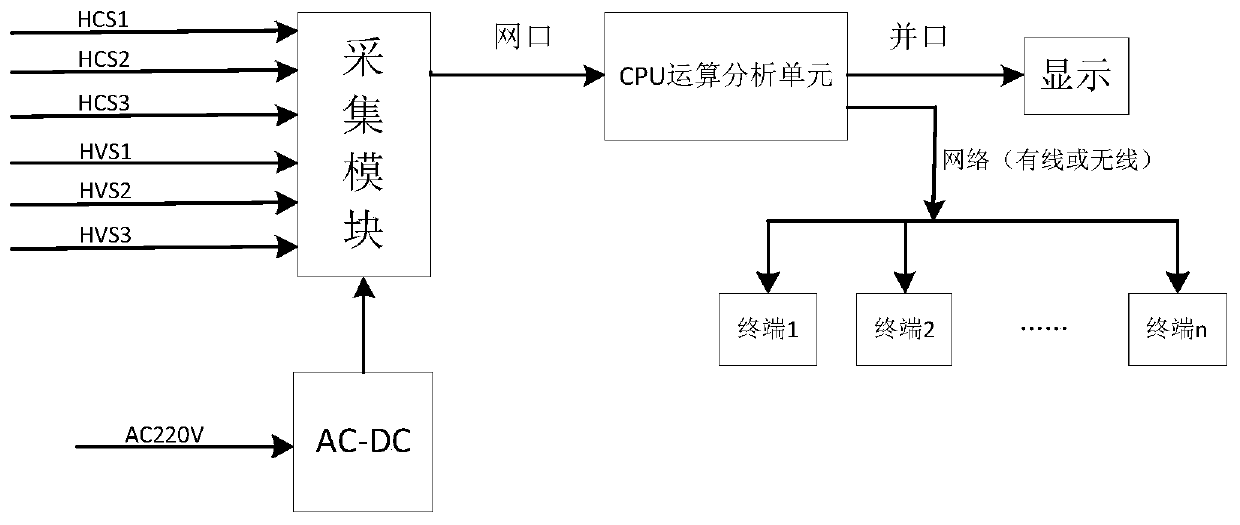

[0035] seefigure 1 The motor online fault monitoring system shown includes multiple voltage sensors, multiple current sensors, data acquisition unit, data transmission unit, power supply unit, operation analysis unit, data analysis result parameter display unit and remote online monitoring unit; The plurality of voltage sensors and the plurality of current sensors are all connected to the data acquisition unit, the power supply unit is connected to the data acquisition unit, the data acquisition unit is connected to the data processing unit through the data transmission unit, and the data processing unit is connected to the data analysis result parameter display unit And remote online monitoring unit.

[0036] The above-mentioned voltage sensor selects the Hall voltage sensor, which has high-frequency response capability and can capture signals with frequency changes of 50KHz and above; select 3-way Hall voltage sensors HCS1, HCS2 and HCS3 to obtain the voltage source informati...

Embodiment 2

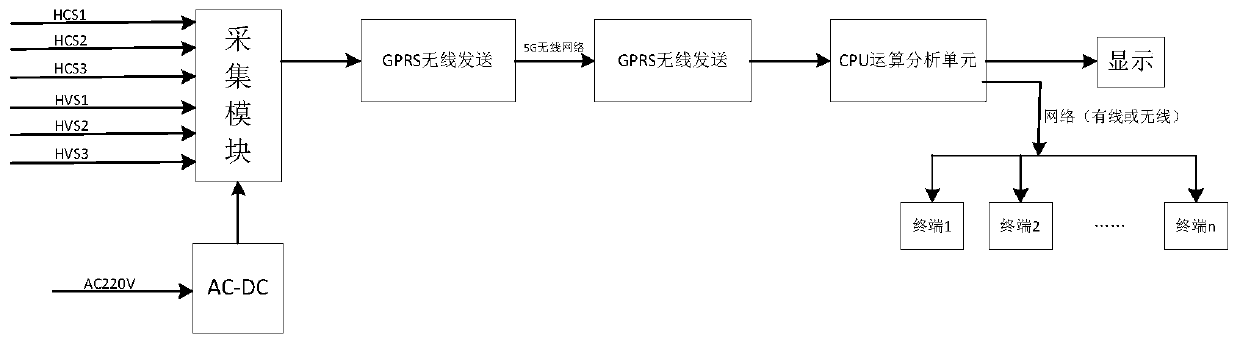

[0050] see figure 2 The difference between this embodiment and Embodiment 1 is that in this embodiment, the data transmission unit selects a 5G network to establish a GPRS wireless transceiver unit.

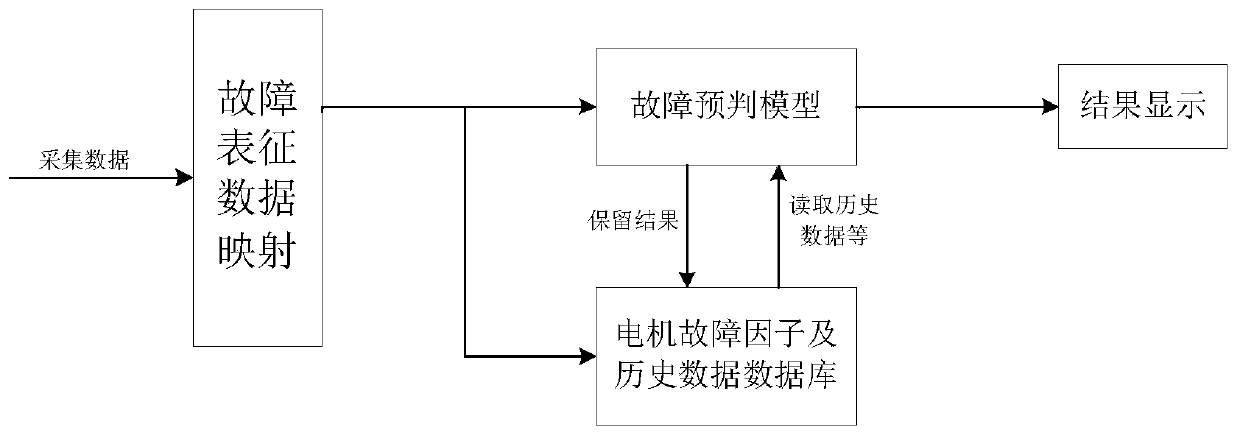

[0051] see image 3 , when using the motor online fault monitoring system, its specific analysis method includes the following steps:

[0052] S1: Use the original digital data collected by the Hall current sensor and Hall voltage sensor, converted by the data acquisition unit, and transmitted by the data transmission unit to extract data that can represent fault information. For the three-phase current data, the time domain waveform is firstly analyzed analyze;

[0053] S2: For the time-domain waveform of phase A current, the N data collected are recorded as Y an , assuming Y' an It is the fundamental wave data of N real-time data fitted; use the minimum mean square error to approximate the signal to be extracted, and calculate Y' an , even if E(e 2 Y )=(Y an -Y' an ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com