Method for adding metal redundant graph

A redundant pattern and metal technology, applied in the field of lithography, can solve the problems of large difference in AEICD of metal lines, inability to achieve metal density and density gradient, etc., to reduce the difference and improve the uniformity of line width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for adding a metal redundancy pattern provided in this embodiment includes the following steps:

[0049] S01: as attached figure 1 As shown, the original layout is provided, and the original layout includes a metal layer composed of metal lines, a via hole between metal layers, a via hole in an active area, and a metal redundant pattern barrier layer.

[0050] S02: Find the metal line Mx with a line width of 50nm through layout logic operation, and screen out the metal edge with a distance greater than 210nm from the adjacent metal lines with different potentials from the metal lines with a line width of 50nm.

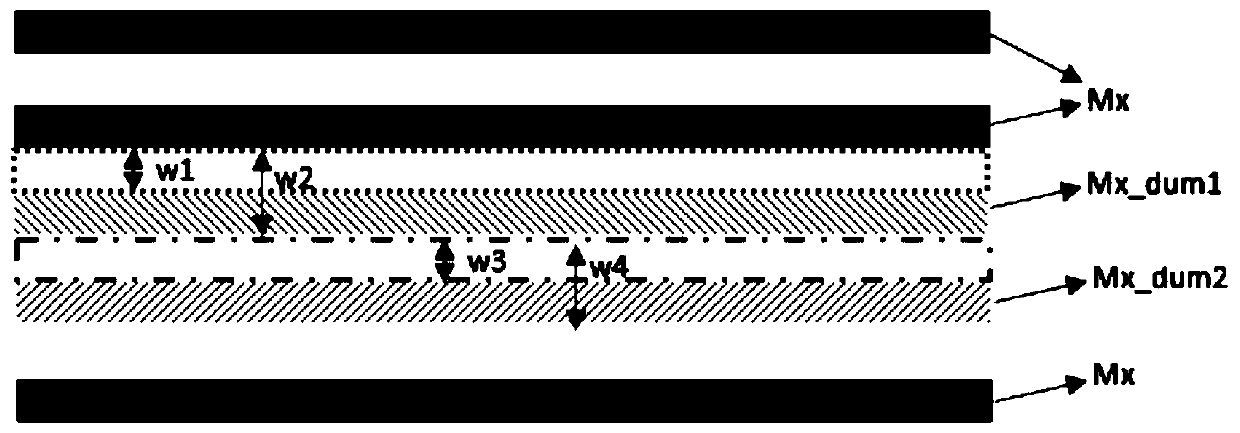

[0051] S03: as attached figure 2 As shown, expand the metal side by W 1 = 80nm and W 2 =130nm, form polygons m1 and m2, through logic operation, draw the overlapping part of polygons m1 and m2, be the temporary metal redundant figure Mx_dum1; width.

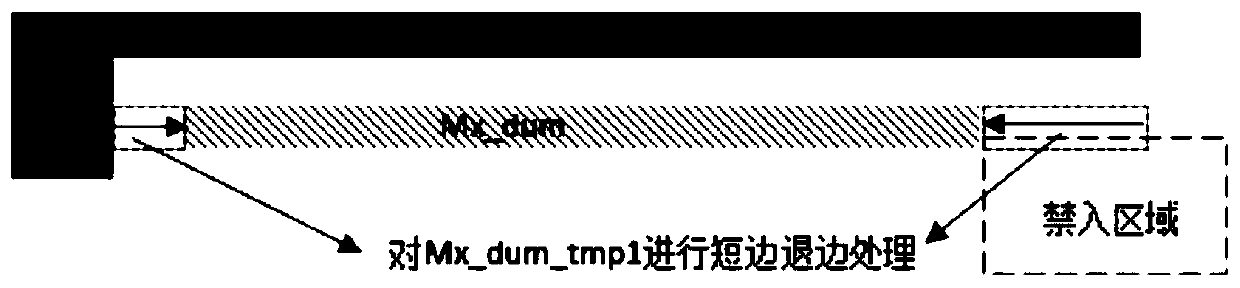

[0052] S04: Perform post-processing on the temporary metal redundancy figure Mx_dum1 to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com