Sealing device

A sealing device and sealing component technology, applied in sealing, engine sealing, packaging, etc., can solve problems such as increased sliding resistance, increased torque, and increased sliding area between the sealing component 810 and the shaft 600, so as to reduce sliding wear and achieve sliding Increased resistance and long-term sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

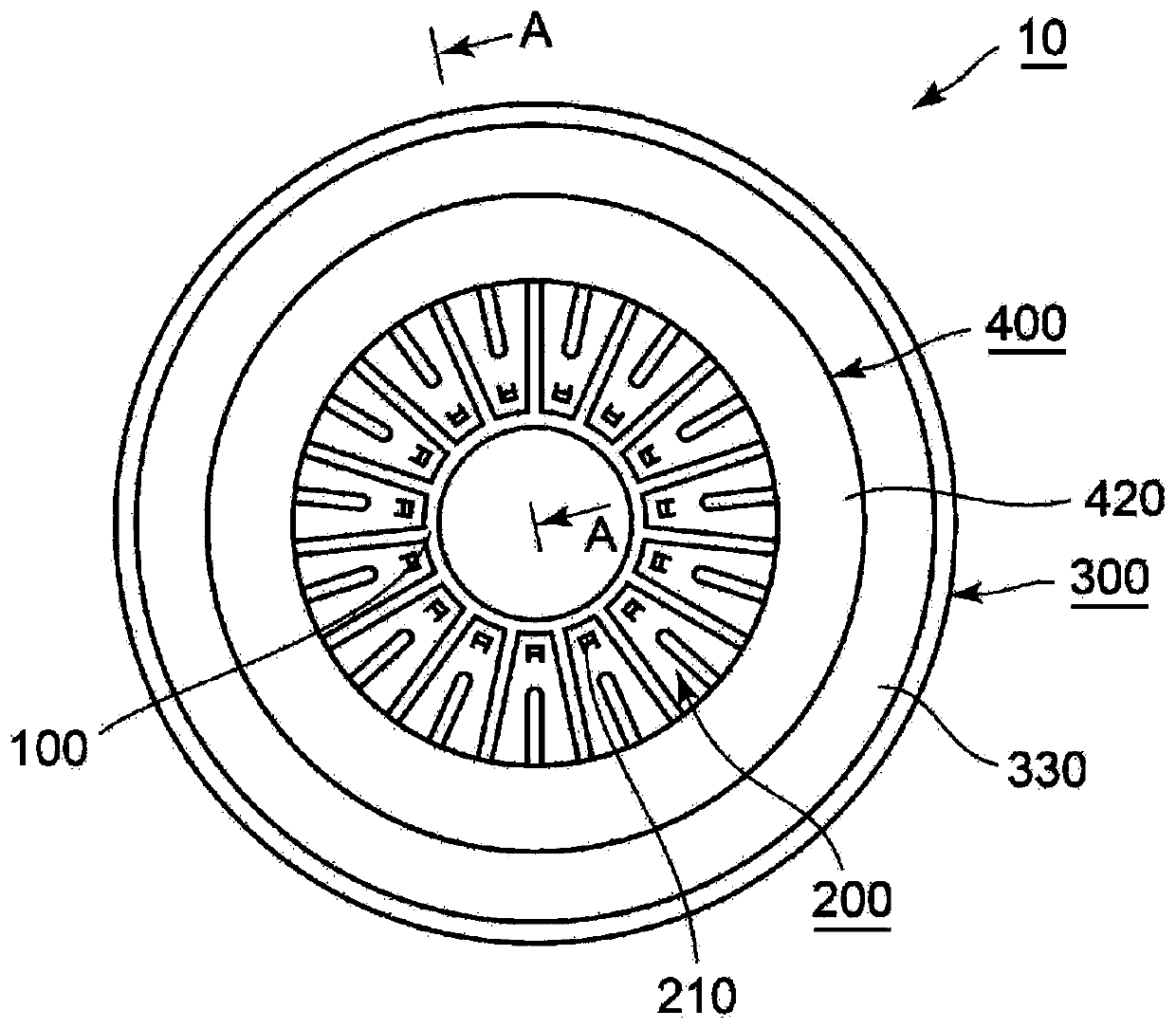

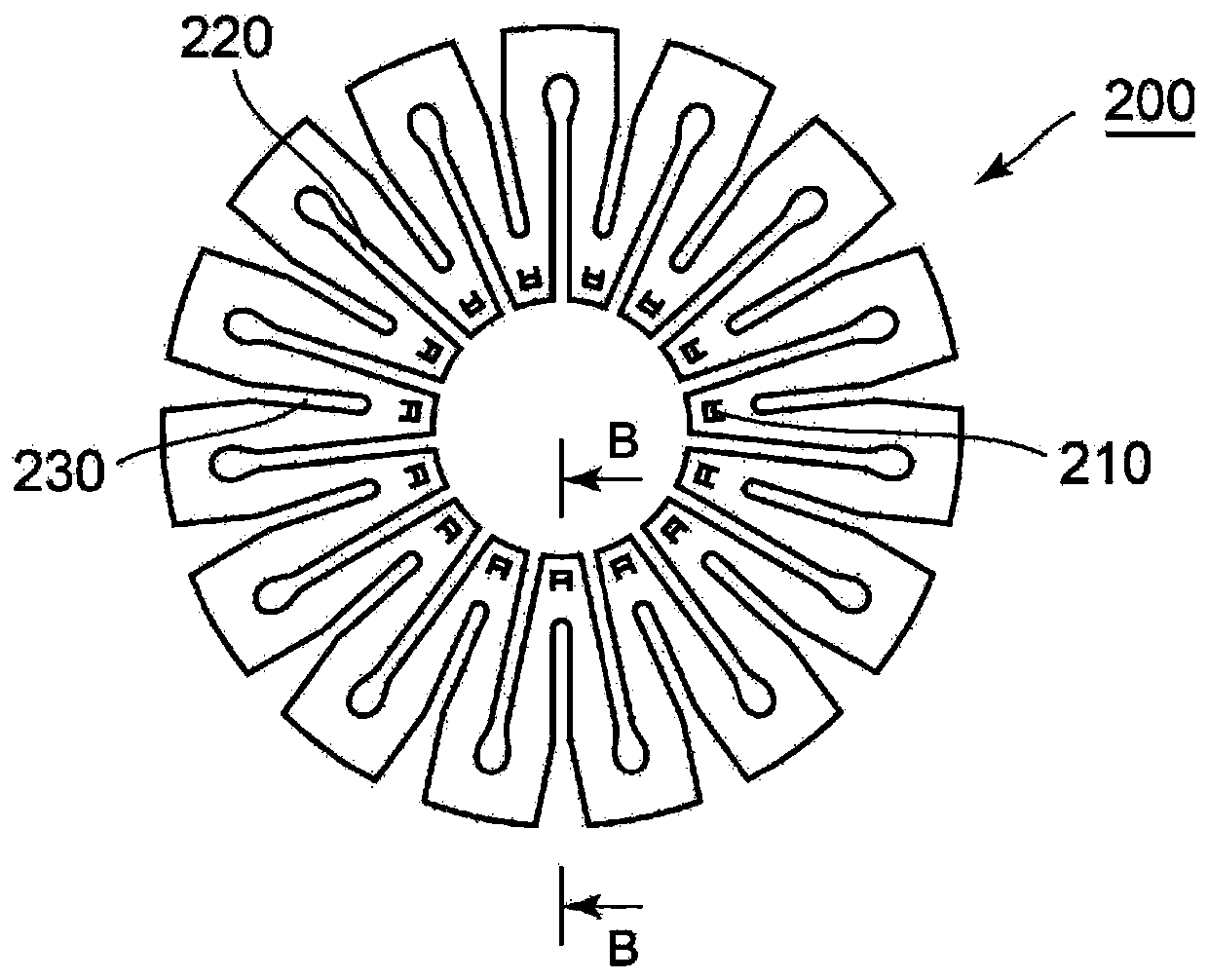

[0037] Hereinafter, with reference to the accompanying drawings, an exemplary detailed description will be given of the manner for implementing the present invention based on embodiments. Among them, the size, material, shape, and relative arrangement of the structural components described in this embodiment, unless otherwise stated, do not mean that the scope of the present invention is limited to these.

[0038] (Example)

[0039] Reference Figure 1 ~ Figure 7 , The sealing device of the embodiment of the present invention is explained. The sealing device 10 of this embodiment is used, for example, in an exhaust gas system such as EGR to seal the annular gap between the relatively rotating shaft 600 and the housing 700. Therefore, the sealing device 10 is used in a high-temperature environment. Here, in the following description, the "sealing target fluid side" refers to the side where the sealing target fluid is sealed. That is, even if the fluid to be sealed is not actually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com