Balloon dilatation catheter, balloon and preparation method of balloon

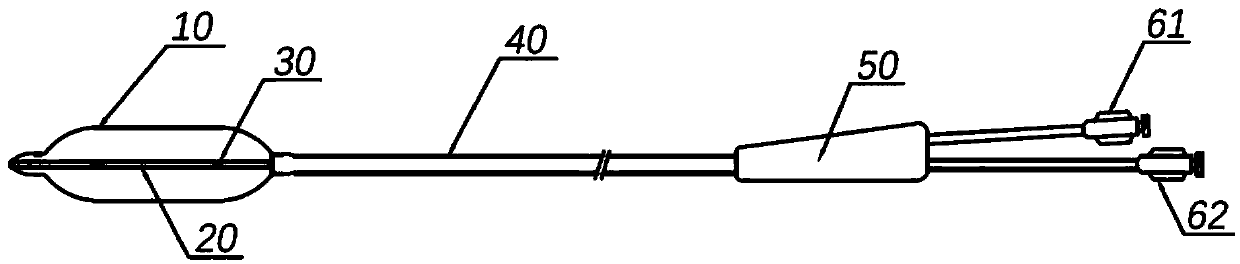

A balloon and expanded state technology, which is applied in the direction of balloon catheters, catheters, and other medical devices, can solve the problems of low puncture resistance and high compliance of valve balloons, and achieve small compliance and high puncture resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

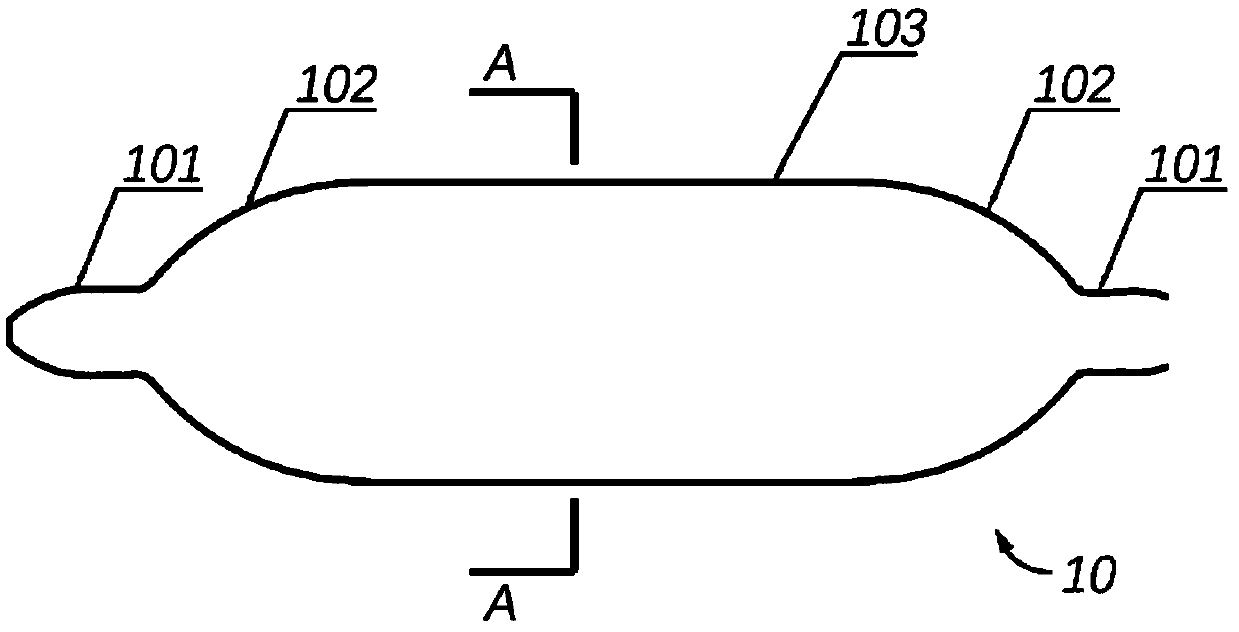

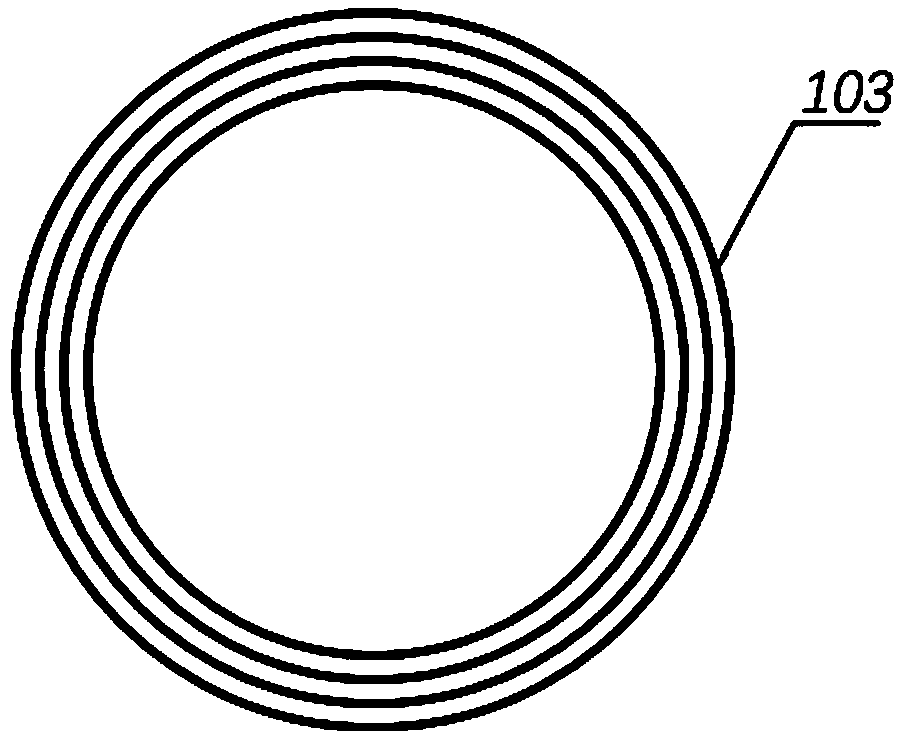

[0060] The balloon 10 in this embodiment is made by blending L25 and TR55, wherein the mass ratio of L25:TR55 is between 9:1 and 7:3. Preferably, the mass ratio of L25:TR55 is 8:2. Among them, please refer to figure 2 and image 3 , the preparation method of the balloon 10 is as follows:

[0061] Step 1: extruding the nylon blended material through an extrusion device to form a hollow tube, and putting the hollow tube into a molding cavity of a balloon forming mold. Here, the nylon blend material is composed of L25 and TR55, and the hollow tubing preferably has a three-layer structure, and the length of the balloon forming mold is preferably 47.8 mm to 50.6 mm.

[0062] Step 2: closing one end of the hollow pipe, and feeding nitrogen gas with a pressure of 8atm to 12atm into the other end of the hollow pipe;

[0063] Step 3: heating the hollow pipe to 100°C-120°C, applying a tension between 200N-300N at both ends of the hollow pipe, and axially stretching the hollow pipe ...

Embodiment 2

[0091] The balloon 10 in this embodiment is made by blending L25 and TR90, wherein the mass ratio of L25:TR90 is between 9:1 and 6:4. Preferably, the mass ratio of L25:TR90 is 7:3. Specifically, the preparation method of the balloon 10 is as follows:

[0092] Step 1: extruding the nylon blended material through an extrusion device to form a hollow tube, and putting the hollow tube into a balloon forming mold. Here, the nylon blend material is composed of L25 and TR90, and the hollow tubing preferably has a two-layer structure, and the length of the balloon forming mold is preferably 39.5mm-41.5mm.

[0093] Step 2: closing one end of the hollow pipe, and feeding nitrogen gas with a pressure of 9.5atm to 11.5atm into the other end of the hollow pipe;

[0094] Step 3: heating the hollow pipe to 110°C-130°C, applying a tension between 220N-300N at both ends of the hollow pipe, and axially stretching the hollow pipe at a stretching speed of 80mm / s-120mm / s The hollow tubing is 20...

Embodiment 3

[0105] The balloon 10 in this embodiment is made by blending L25, TR55 and TR90, wherein the mass percentage of TR90 is 10%, and the mass ratio of L25:TR55 is between 7:2 and 5:4. Preferably, the mass ratio of L25:TR55:TR90 is 6:3:1.

[0106] Specifically, the preparation method of the balloon 10 is as follows:

[0107] Step 1: extruding the nylon blended material through an extrusion device to form a hollow tube, and putting the hollow tube into a balloon forming mold. Here, the nylon blend material is composed of L25, TR55 and TR90, and the hollow tube preferably has a three-layer structure, and the length of the balloon forming mold is preferably between 57.5 mm and 59.5 mm.

[0108] Step 2: closing one end of the hollow pipe, and feeding nitrogen gas with a pressure of 11.5atm to 13.5atm into the other end of the hollow pipe, and sealing the other end;

[0109] Step 3: heating the hollow pipe to 100°C-120°C, applying a tension between 160N-220N at both ends of the hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com