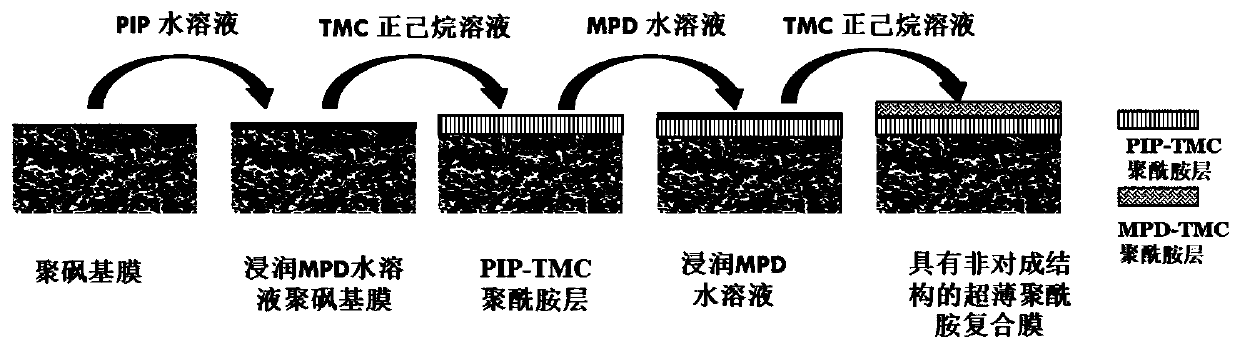

Preparation method of reverse osmosis membrane with ultrathin asymmetric polyamide interception layer

A technology of polyamide layer and reverse osmosis membrane, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as decline, and achieve the effect of simple preparation process, easy control of conditions, and small amount of raw materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

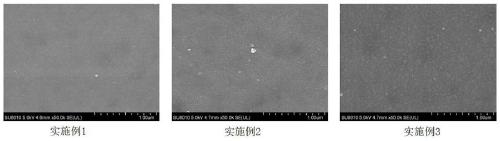

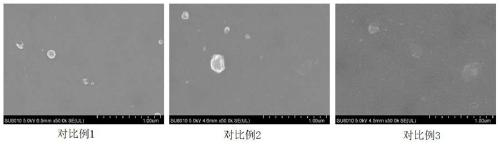

Examples

Embodiment 1

[0034] The water phase containing PIP at a concentration of 0.05% was used to cover the membrane surface of the porous polysulfone-bottomed membrane. Place it horizontally for 2 minutes to fully infiltrate the surface of the polysulfone membrane with the PIP aqueous solution. The surface of the polysulfone-based membrane was then purged with nitrogen to remove excess PIP aqueous phase. Afterwards, place on the basement membrane horizontally, slowly pour n-hexane containing 0.01%wt TMC at a concentration, and wait for it to spread naturally on the basement membrane and completely cover the basement membrane. Start timing, and the interfacial polymerization reaction time is 1 min. Tilt the basement membrane so that the n-hexane liquid containing TMC flows away and leaves the surface of the membrane. This moment is regarded as the end point of the interfacial polymerization reaction, the stop moment. A bottom separating layer of polyamide was built up. Afterwards, place the m...

Embodiment 2

[0036] As in the process steps of embodiment 1, wherein only the concentration of MPD and TMC two reactive monomers in the secondary interfacial polymerization is changed. Wherein the concentration of MPD is 0.1%wt, and the concentration of TMC is 0.02%wt.

Embodiment 3

[0038] As in the process steps of embodiment 1, wherein only the concentration of MPD and TMC two reactive monomers in the secondary interfacial polymerization is changed. Wherein the concentration of MPD is 0.2%wt, the concentration of TMC is 0.04%wt

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com