A process for preparing foamed SBS modified asphalt and mixture from SBS latex

A technology of modified asphalt and process method, which is applied in the field of preparing foamed SBS modified asphalt and mixtures from SBS latex, and can solve the problem that the warm mixing technology of foamed SBS modified asphalt mixtures has not been widely promoted, has strong cohesion, and is difficult to foam Major problems, achieve significant economic and social benefits, save production costs, and avoid high-temperature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

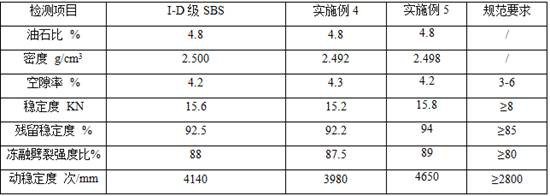

Examples

Embodiment 1

[0042] A kind of SBS latex prepares the technological method of foam SBS modified asphalt:

[0043] 1000 g of base asphalt was heated to a molten state (135°C), and injected into a foaming system containing a colloid mill at the same time as 30 g of normal-temperature SBS latex with a solid content of 40%, and the surfactant and water in the SBS latex were used as foaming agents , wherein SBS is used as a modifier, and foamed SBS modified asphalt is obtained under the action of a foaming system containing a colloid mill.

Embodiment 2

[0045] A kind of SBS latex prepares the technological method of foam SBS modified asphalt:

[0046] 1000 g of base asphalt was heated to a molten state (140°C), and injected into a foaming system containing a colloid mill at the same time as 50 g of normal-temperature SBS latex with a solid content of 40%, and the surfactant and water in the SBS latex were used as foaming agents , wherein SBS is used as a modifier, and foamed SBS modified asphalt is obtained under the action of a foaming system containing a colloid mill.

Embodiment 3

[0048] A kind of SBS latex prepares the technological method of foam SBS modified asphalt:

[0049] 1000 g of base asphalt was heated to a molten state (135°C), and injected into a foaming system containing a colloid mill at the same time as 80 g of normal-temperature SBS latex with a solid content of 40%, and the surfactant and water in the SBS latex were used as foaming agents , wherein SBS is used as a modifier, and foamed SBS modified asphalt is obtained under the action of a foaming system containing a colloid mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com