Ocean deep drilling exploration and well drilling operation drill column suspending method

A deep drilling technology, applied in the direction of drilling equipment, drill pipes, drill pipes, etc., can solve the problems of low efficiency of elevator switching, large lateral force of drill string, and many joint failures, etc., to solve the problem of switching power elevators and improving the bearing capacity Ability to solve the effect of the joint being too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

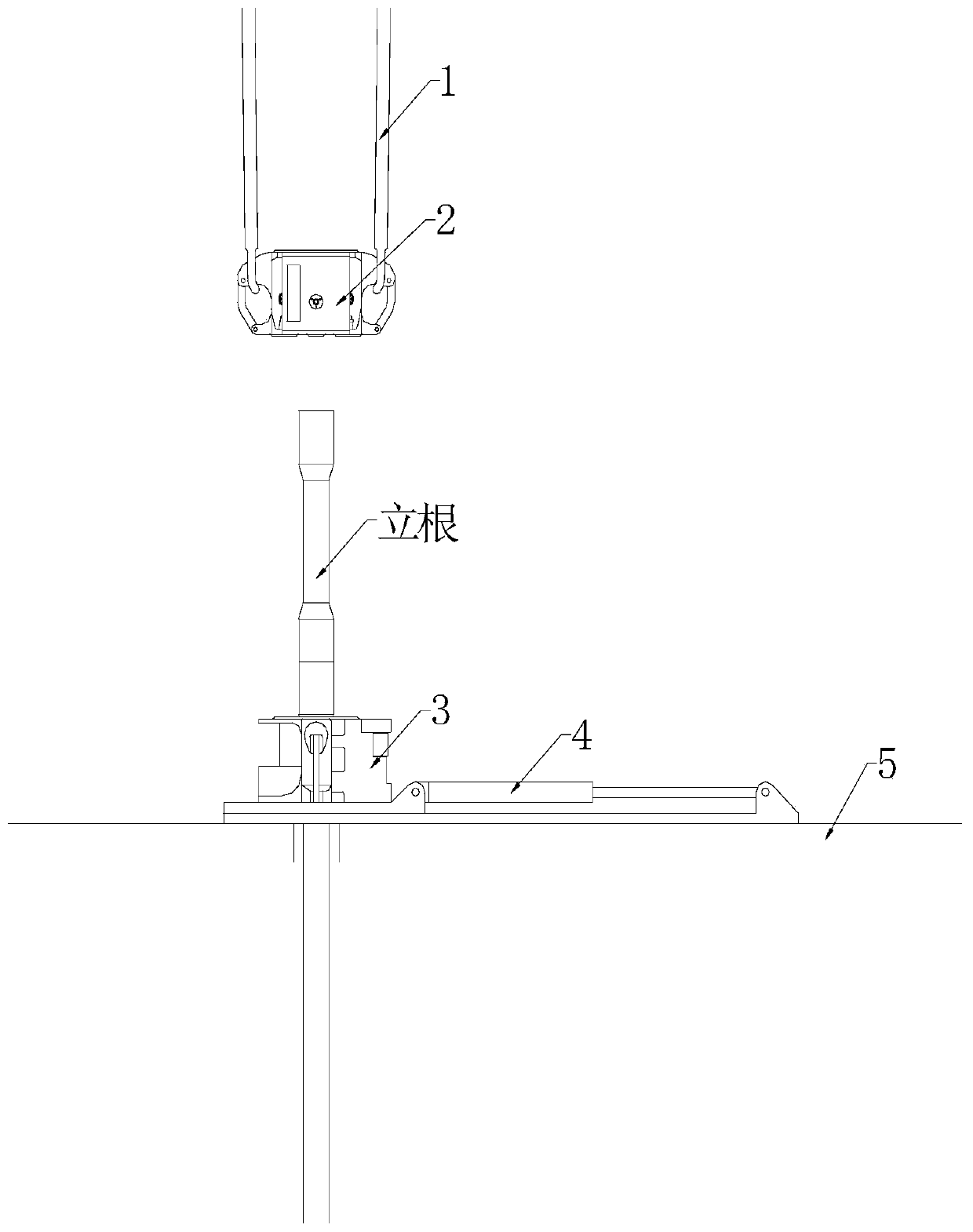

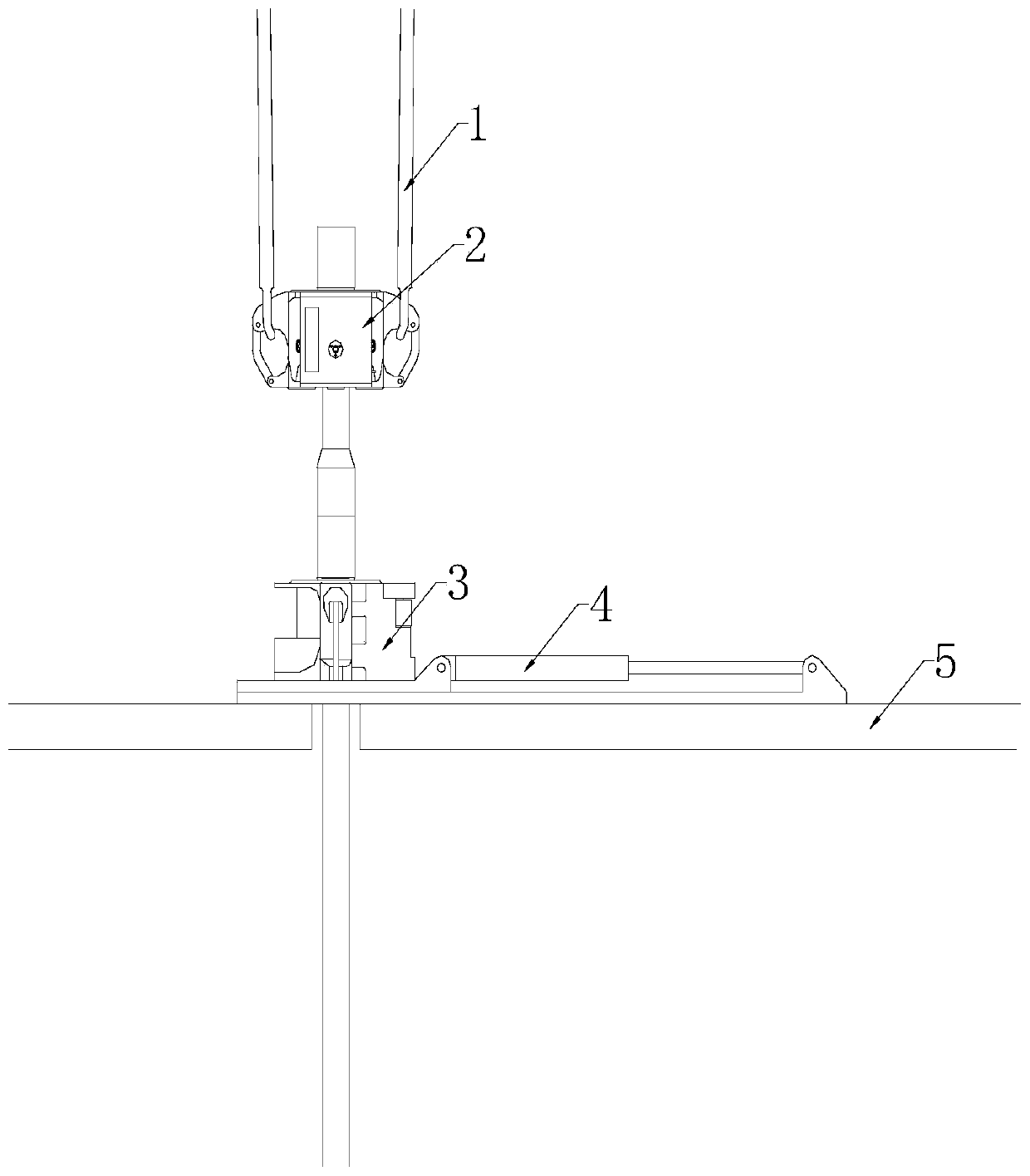

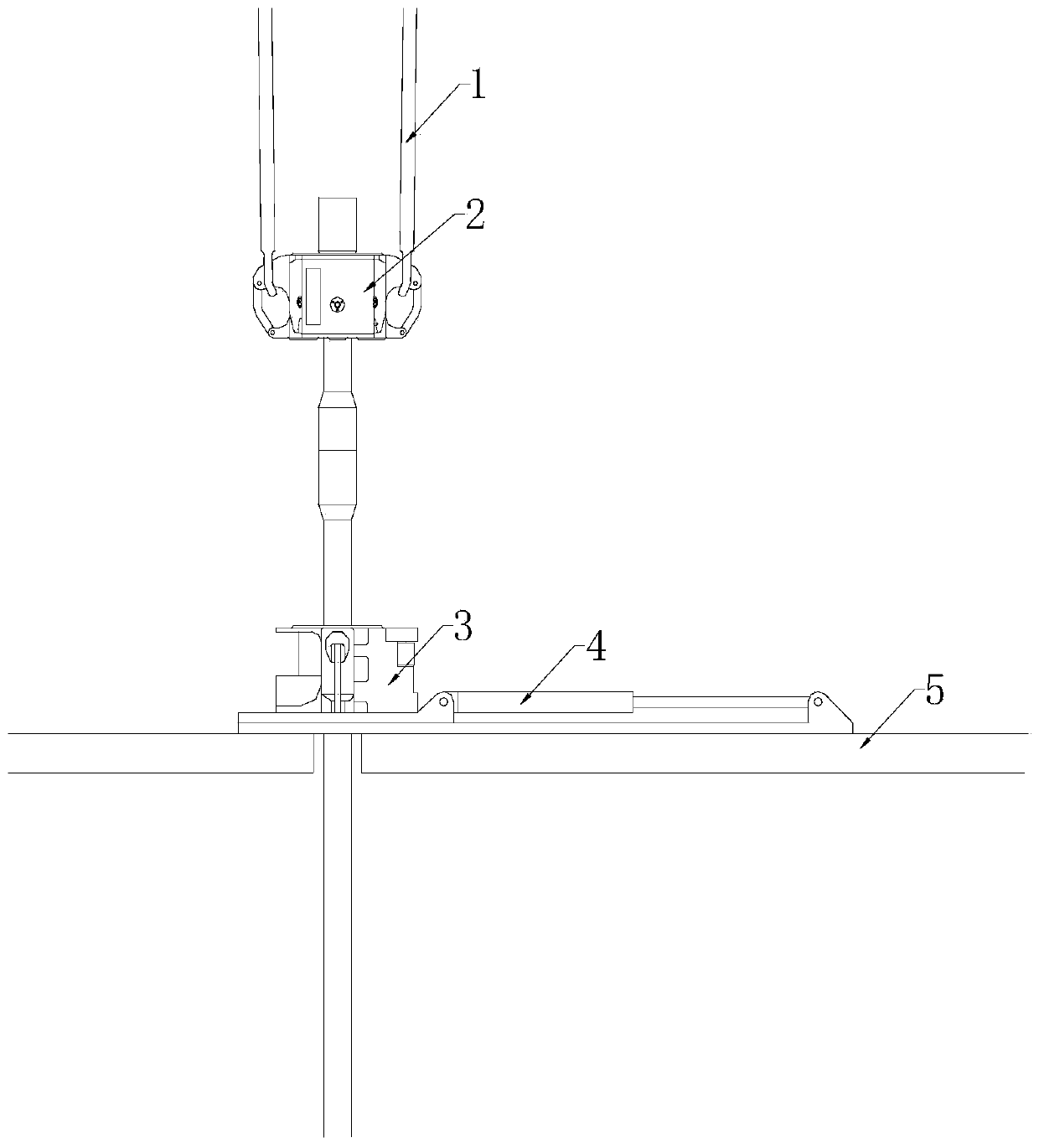

[0023] Such as Figure 1 to Figure 6 Shown, a kind of drill string suspending method of deep ocean drilling drilling operation comprises the following steps:

[0024] Step 1: Set up the stand and temporarily connect the drill pipe in the well, and pre-connect a short drill pipe to the uppermost end (that is, the top) of the stand. The stand after the short drill pipe is pre-connected is stored vertically on the storage area of the derrick. Right above the wellhead of the well, the length of the short drill pipe is usually shorter than that of the drill pipe, and the short drill pipe can be pre-connected to the top of the stand by thread make-up. A stand usually consists of at least 3-4 drill pipes connected in sequence. The drill pipe includes the rod body and the male joint and the female joint arranged at both ends of the rod body, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com