Surface-enhanced Raman composite test paper

A surface-enhanced Raman and test paper technology, which is applied in the detection field, can solve the problems of lower amplification factor and poor stability of sol dispersion, and achieve the effects of improved sensitivity, high repeatability and batch-to-batch consistency, and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

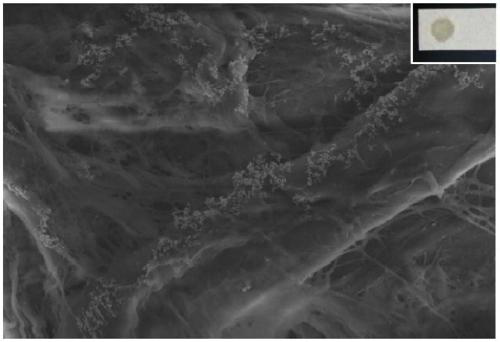

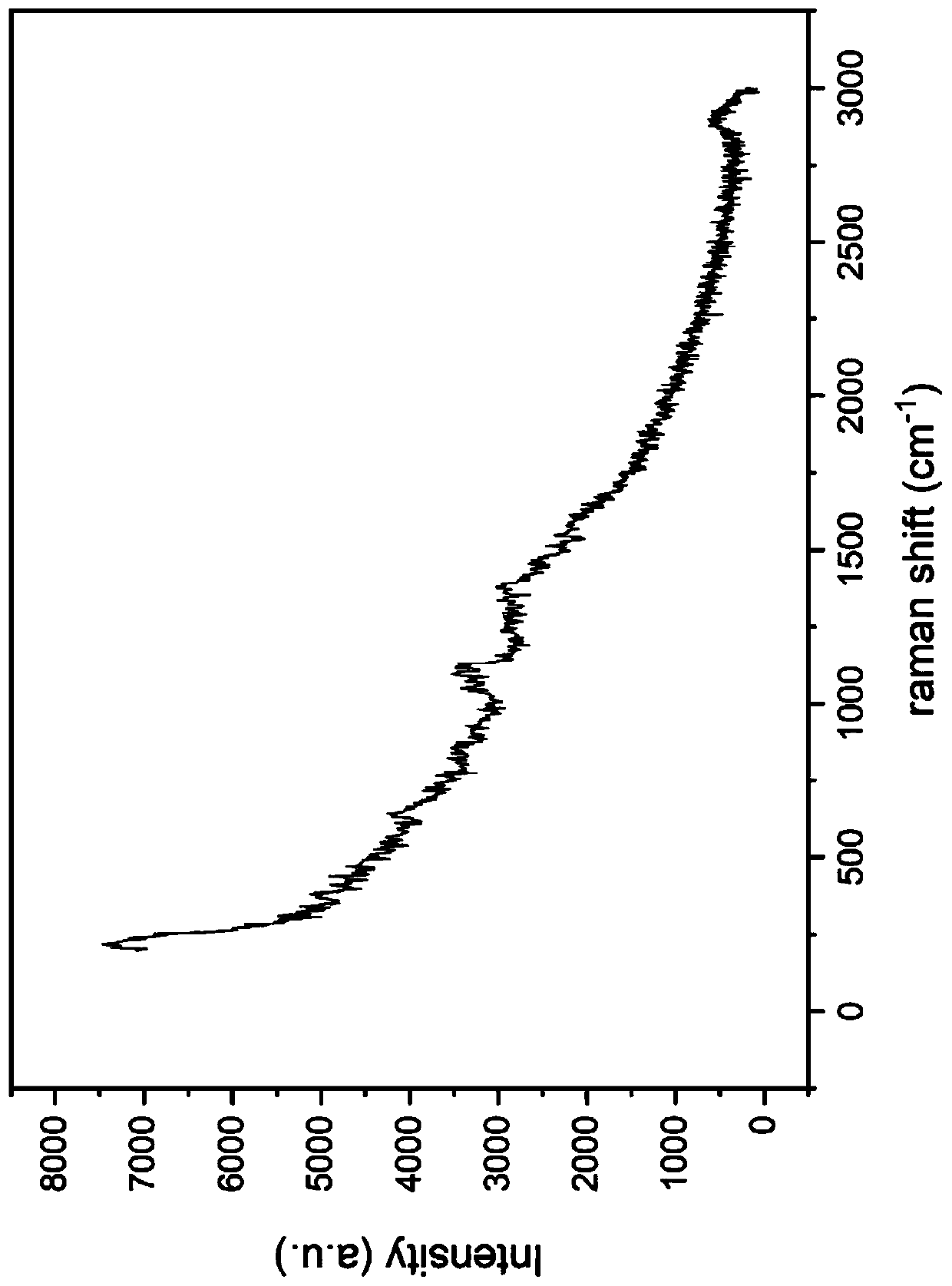

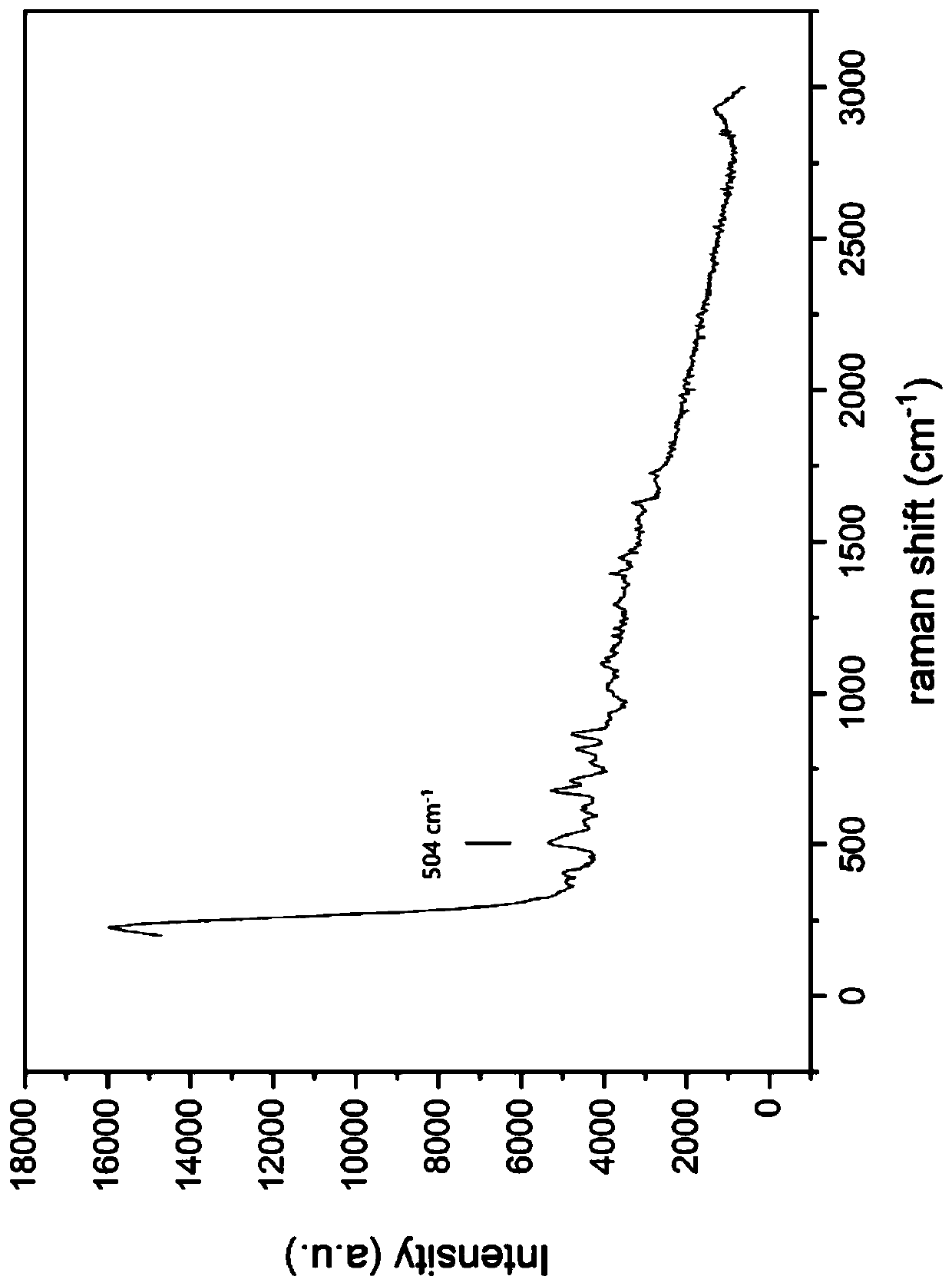

Image

Examples

preparation example Construction

[0044] A preparation method for surface-enhanced Raman composite test paper, comprising the following steps:

[0045] (1) Prepare AgNPs sol and AuNPs sol according to a predetermined volume ratio;

[0046] (2) The AgNPs sol and the AuNPs sol are sequentially mixed, concentrated, and ink-formed to obtain a composite material of the AgNPs sol and the AuNPs sol;

[0047] (3) The composite material is dispersed on the carrier by printing to obtain a composite test paper;

[0048] (4) The composite test paper is post-treated to obtain a surface-enhanced Raman composite test paper.

[0049] Step (2) includes: step 2-1) mixing: mixing the AgNPs sol and the AuNPs sol obtained in step (1) to obtain a mixed sol; step 2-2) concentrating: mixing the mixed sol in a centrifuge Centrifuge in the machine until gray precipitate appears at the bottom of the centrifuge tube; Step 2-3) Inking: Keep the centrifuge tube stable, remove the liquid on the upper layer, and add the ink agent to the re...

Embodiment 1

[0056] A surface-enhanced Raman composite test paper, comprising: a carrier and a test layer uniformly laid on the surface of the carrier; the test layer is a composite material of AgNPs sol and AuNPs sol, and the volume of AgNPs sol and AuNPs sol in the composite material The ratio was 3:2 and the density of the composite material on the test layer was about 0.01 mg / mm2. The carrier is medium-speed filter paper.

[0057] Among them, AgNPs sol and AuNPs sol are prepared by conventional methods.

[0058] The preparation method of the surface-enhanced Raman composite test paper comprises the following steps:

[0059] (1) Prepare AgNPs sol and AuNPs sol according to a predetermined volume ratio;

[0060] (2) The AgNPs sol and the AuNPs sol are sequentially mixed, concentrated, and ink-formed to obtain a composite material of the AgNPs sol and the AuNPs sol;

[0061] Step (2) includes: step 21) mixing: mixing the AgNPs sol and the AuNPs sol obtained in step (1) in a volume rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com