Thin film packaging structure, thin film packaging method and concave hole design method

A technology of thin film packaging and concave holes, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of increased waiting time, poor production efficiency, increased process time, etc., to reduce the contact angle and improve Flattening effect, wettability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The terms "first", "second", etc. used herein do not specifically refer to a sequence or order, nor are they used to limit the present application, but are only used to distinguish components or operations described with the same technical terms. .

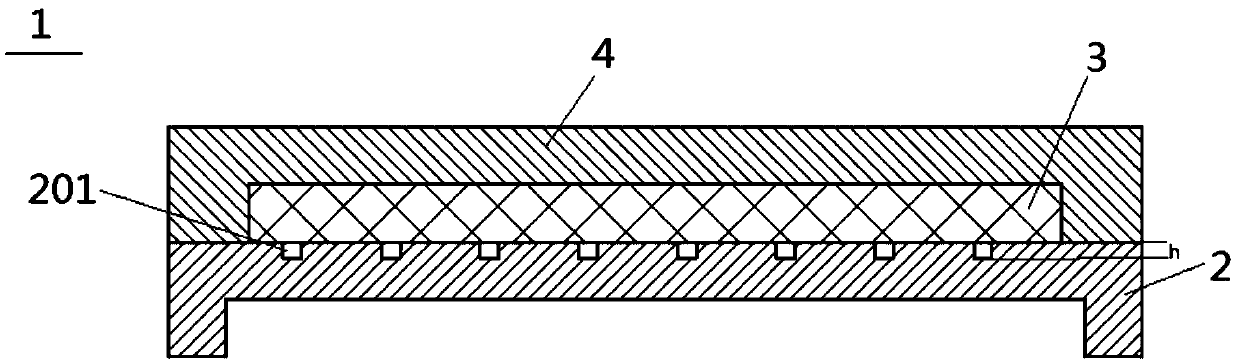

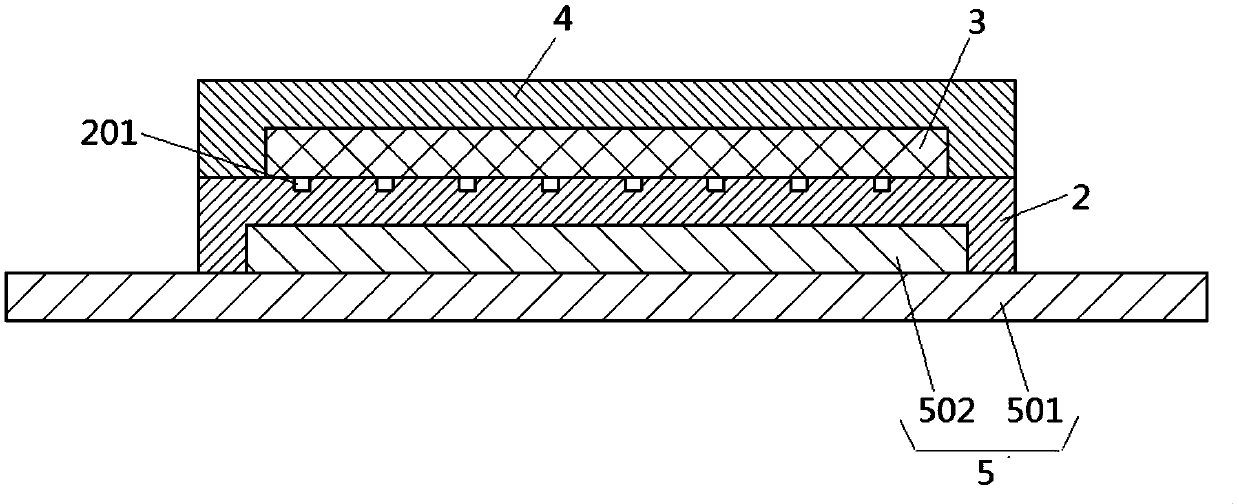

[0023] An embodiment of the present invention discloses a thin film encapsulation structure 1, please refer to Figure 1-4 As shown, it is applied to the thin film encapsulation of an organic light emitting diode (OLED) device 5, and the thin film encapsulation structure 1 includes a first inorganic encapsulation layer 2, an organic encapsulation layer 3 and a second inorganic encapsulation layer 4, wherein:

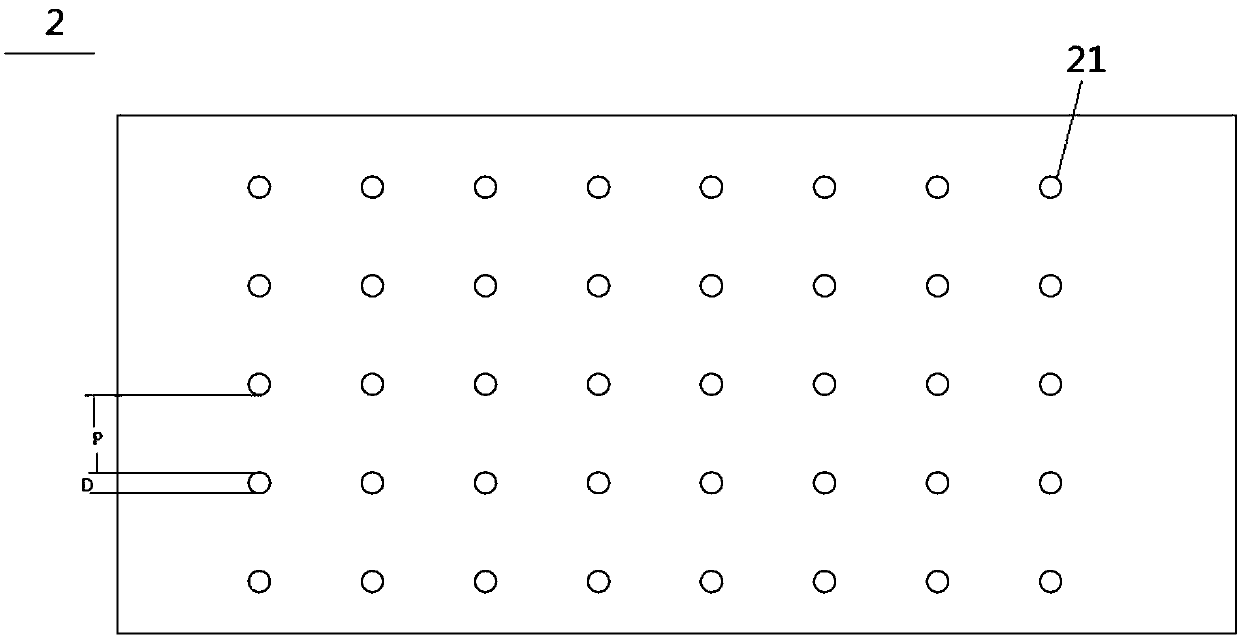

[0024] Please refer to figure 1 As shown, the first inorganic encapsulation layer 2 is arranged at the lower end of the thin film encapsulation structure 1. In the present invention, there is no special requirement for the material selection of the first inorganic encapsulation layer 2, and it can be selected by refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com