A kind of preparation method of high tenacity dyeable fully degradable pla-pha material

A PLA-PHA, full-degradation technology, applied in the field of preparation of fully-degradable PLA-PHA materials, can solve problems such as the influence of tensile strength, achieve the effects of ensuring crystallization, improving heat resistance, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

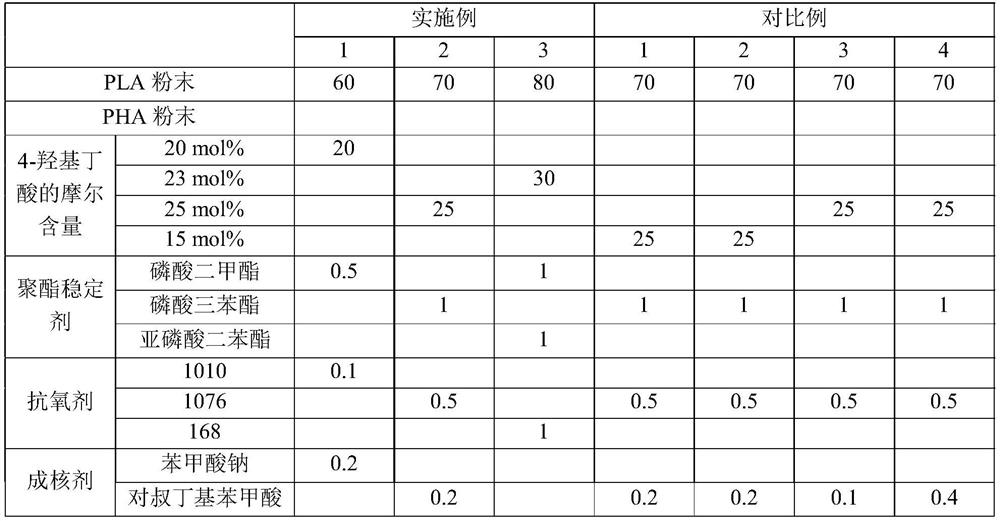

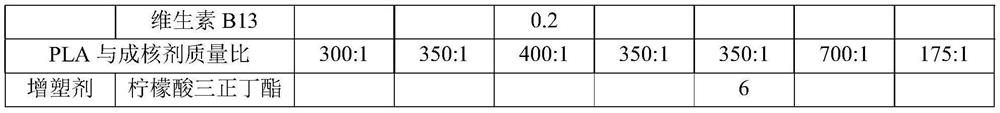

[0031] The present invention is described in further detail now in conjunction with embodiment.

[0032] The preparation method of high tenacity dyeable fully degradable PLA-PHA material is characterized in that: comprising the following steps:

[0033] (1) Take PLA powder and PHA powder, mix after drying, obtain mixture;

[0034] (2) Add polyester stabilizer, antioxidant and nucleating agent to the mixture in step (1), mix thoroughly, melt and extrude through a twin-screw extruder, water-cool and cut into pellets, and dry to make master batches.

[0035] Wherein, the drying method of the polyhydroxyalkanoate powder in step (1) is: put the polyhydroxyalkanoate powder into the vacuum drum drying equipment and dry for 8-10 hours, the drying temperature is 70-80°C, the polyhydroxyalkanoate The water content of the ester powder is controlled below 30PPM; the drying method of the polylactic acid powder in step (1) is: put the polylactic acid powder in a vacuum drum drying equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com