Straddle type monorail automatic ice and snow removing vehicle

A straddle-type monorail, automatic technology, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of increased energy consumption, bulky, difficult to reach the track, etc., to achieve increased flexibility, small overall size, and impact prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

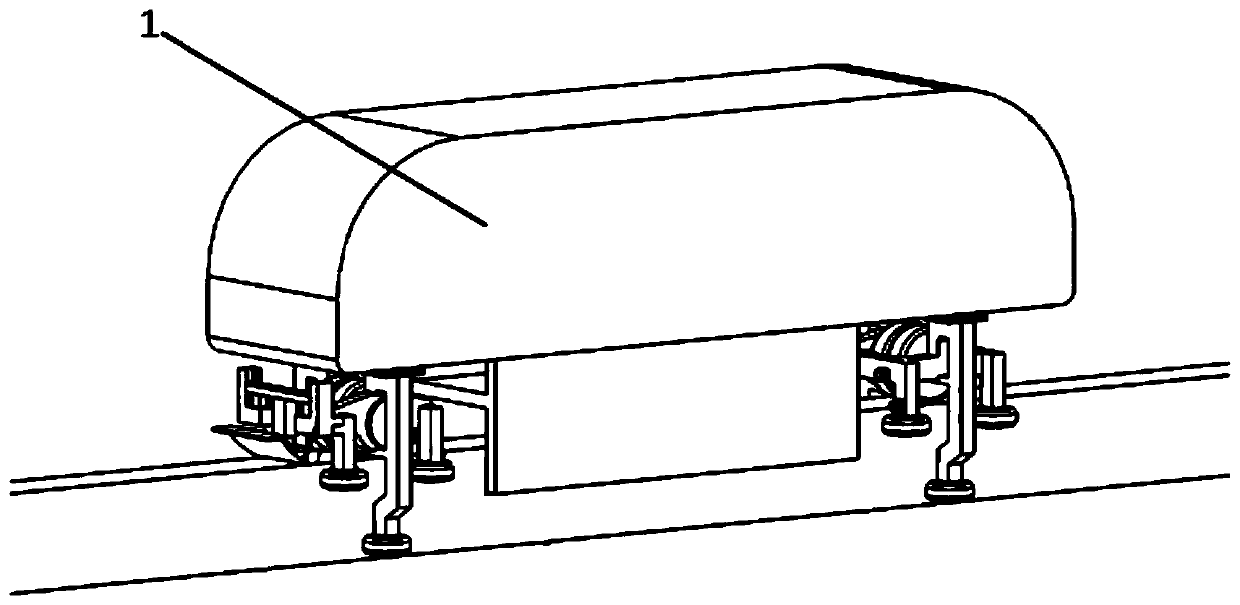

[0040]A straddle type monorail automatic deicing vehicle provided by a preferred embodiment of the present invention includes a car body 1, a snow removal mechanism, a steering mechanism and a deicing part. The car body 1 is provided with a storage battery, an industrial computer, a GPS positioning device, a heating device and a high-temperature centrifugal fan, the steering mechanism includes two bogies respectively installed at the front and rear under the car body 1, the snow removal mechanism is installed on the bogies through the mounting seat 8, and the deicing part includes two bogies installed under the car body 1. Hot air heating tank and vision sensor 20 installed on the bogie;

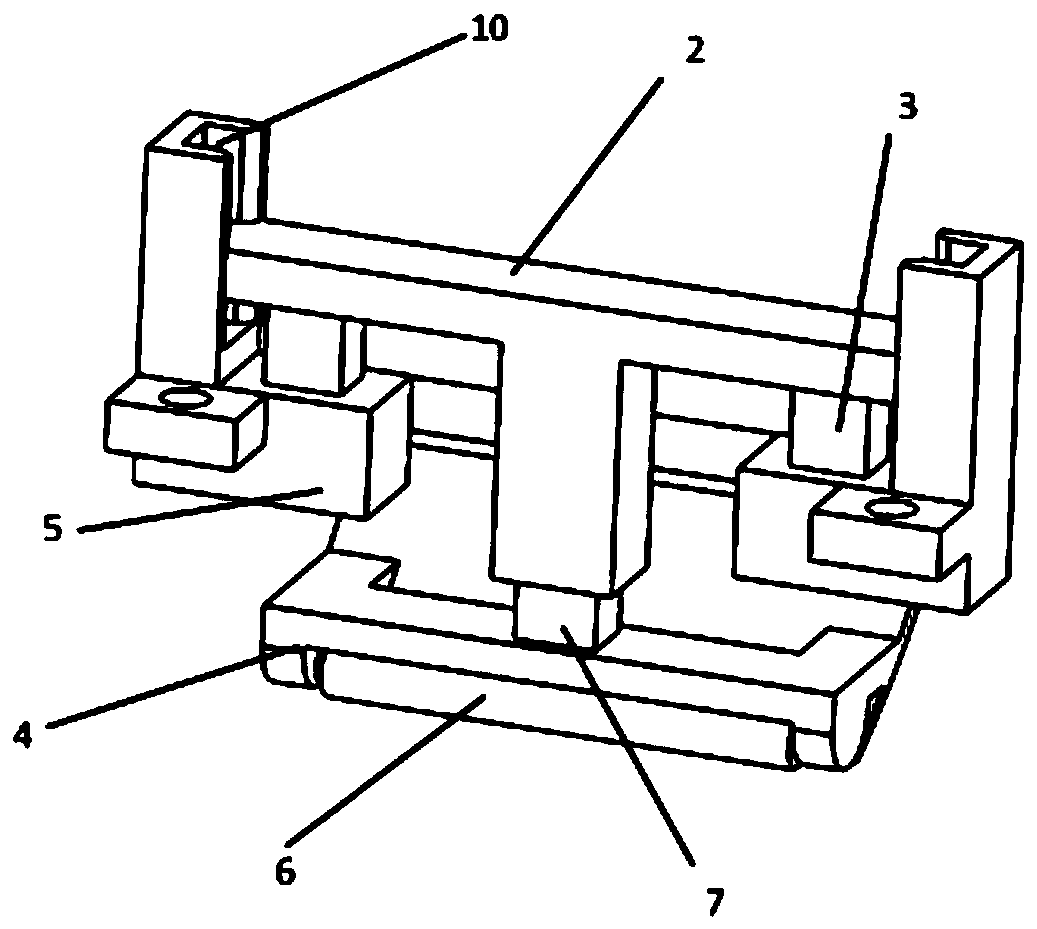

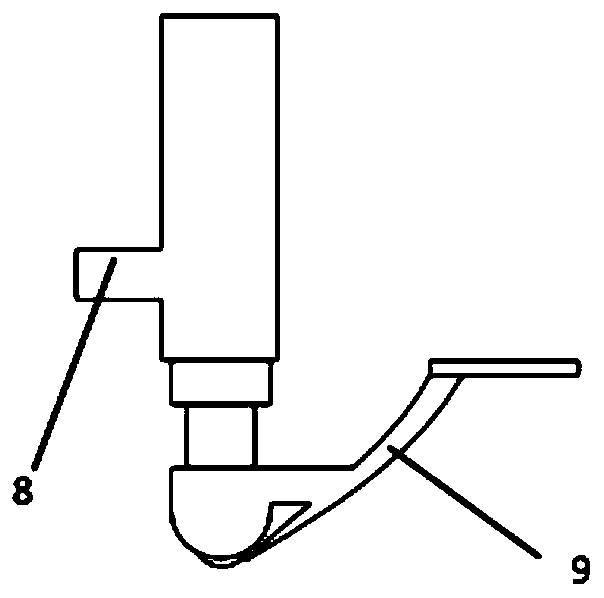

[0041] The snow removal mechanism comprises a support platform 5 fixedly connected with the mounting seat 8, a guide groove 10 and a telescopic electromagnet 3 are fixedly connected on the support platform, and the telescopic electromagnet 3 other end is fixedly connected with the T-shaped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com