A kind of bog recovery system and working method of lng power ship

A recovery system and ship technology, applied in the field of reliquefaction, can solve problems such as instability and complexity, and achieve the effects of reducing energy waste, reducing system load, and improving load regulation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

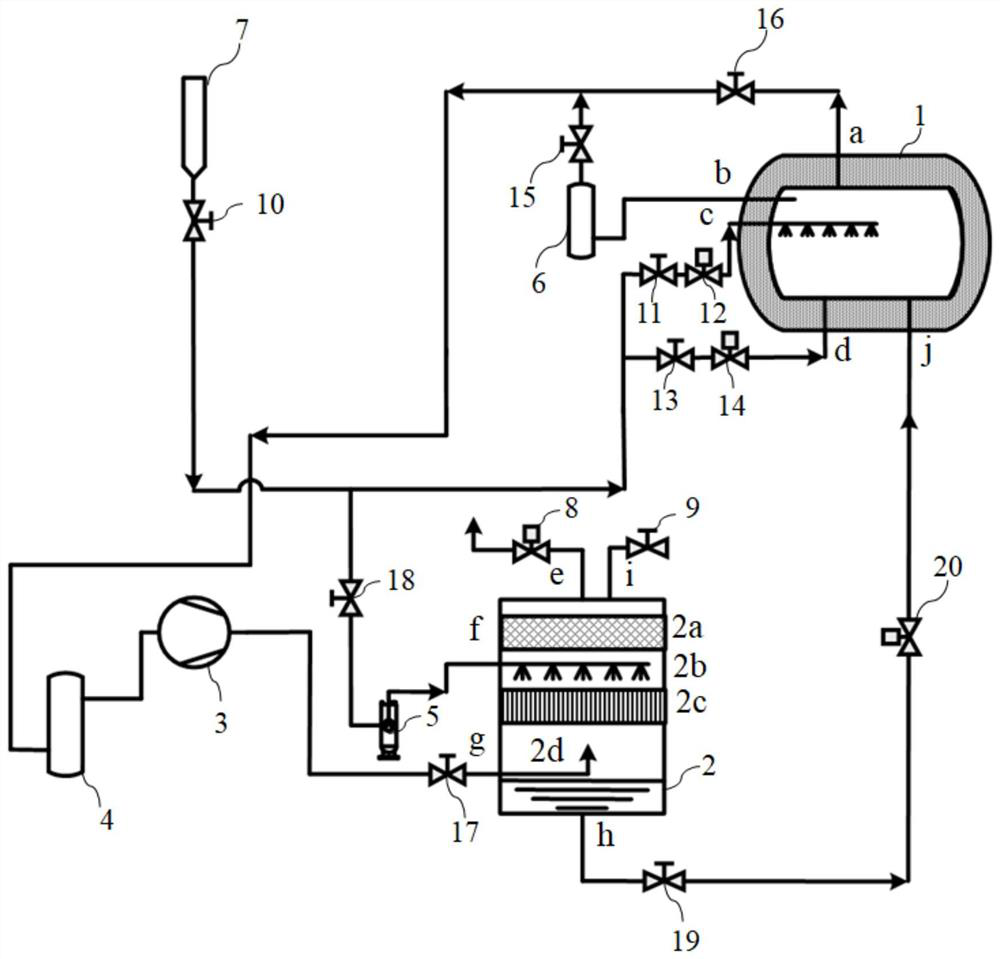

[0027] Such as figure 1Shown: It is a BOG recovery system of an LNG-powered ship according to the present invention, which includes an LNG storage tank 1, a heat exchanger 2 and an LNG filling device 7, wherein the heat exchanger 2 is isolated from top to bottom in sequence There are filter screen 2a, spray pipe 2b, filler 2c and intake pipe 2d, spray pipe 2b is helpful for sufficient heat exchange between subcooled LNG and BOG, and improves heat exchange efficiency;

[0028] The LNG filling device 7 is sequentially connected to the second valve 11, the first regulating valve 12, and the inlet c of the spray pipe 2b of the LNG storage tank 1 through pipelines, and the other path is sequentially connected to the third valve 13 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com