Reusable nanofiber mask, protective film, and preparation method and application thereof

A nanofiber and nanocellulose technology, applied in applications, protective clothing, clothing, etc., can solve the problem that nanofiber filter membranes and anti-smog masks cannot be reused, so as to improve the protection performance and service life, and achieve isolation , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Preparation of mask protective film

[0057] In this example, a single-channel inclined wire paper machine is used for one-time copying, and the isolation layer and the support layer are prepared respectively. The two layers are laminated and hot-pressed to obtain a mask protective film with a double-layer structure. The specific preparation method is as follows:

[0058] Step a: According to the raw material formula, the raw materials of the isolation layer and the support layer are mixed with water respectively to obtain the slurry of the isolation layer and the support layer, the slurry concentration of the isolation layer is 0.0001wt%, and the slurry concentration of the support layer is 0.01wt%;

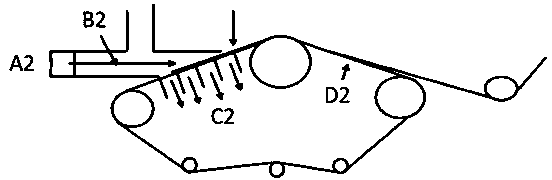

[0059] Step b: Separately load the slurry of the isolation layer and the support layer into the single-pass inclined wire paper machine, such as figure 1 As shown, a single-layer isolation layer and a support layer are obtained after one-time copying, pressing, drying, an...

Embodiment 2

[0061] Preparation of mask protective film

[0062] In this embodiment, a multi-channel inclined wire paper machine is used for one-time copying to realize the compounding of the isolation layer and the support layer, and obtain a mask protective film with a double-layer structure. The specific preparation method is as follows:

[0063] Step a: According to the raw material formula, the raw materials of the isolation layer and the support layer are mixed with water respectively to obtain the slurry of the isolation layer and the support layer, the slurry concentration of the isolation layer is 0.0026%, and the slurry concentration of the support layer is 0.055%;

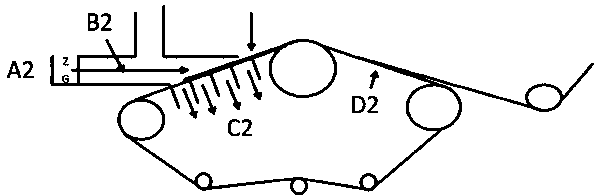

[0064] Step b: Separately load the slurry of the isolation layer and the support layer into the inclined wire paper machine, such as figure 2 As shown, the isolation layer slurry is loaded into the first layer, and the support layer slurry is loaded into the second layer, so that the two layers of slurry are stacked...

Embodiment 3

[0066] Preparation of mask protective film

[0067] This embodiment is basically the same as Embodiment 2, except that the formulations of the isolation layer and the support layer are different, and the hot-pressing parameters are different.

[0068] The formula of embodiment 1-3, compound mode and hot pressing parameter, as shown in table 1 below

[0069] Table 1

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com