Abandoned steel pipe sorting device for constructional engineering

A technology of construction engineering and sorting device, which is applied in the field of waste steel pipe sorting device for construction engineering, and can solve problems such as puncture injuries, increased workload of workers, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is realized through the following technical solutions:

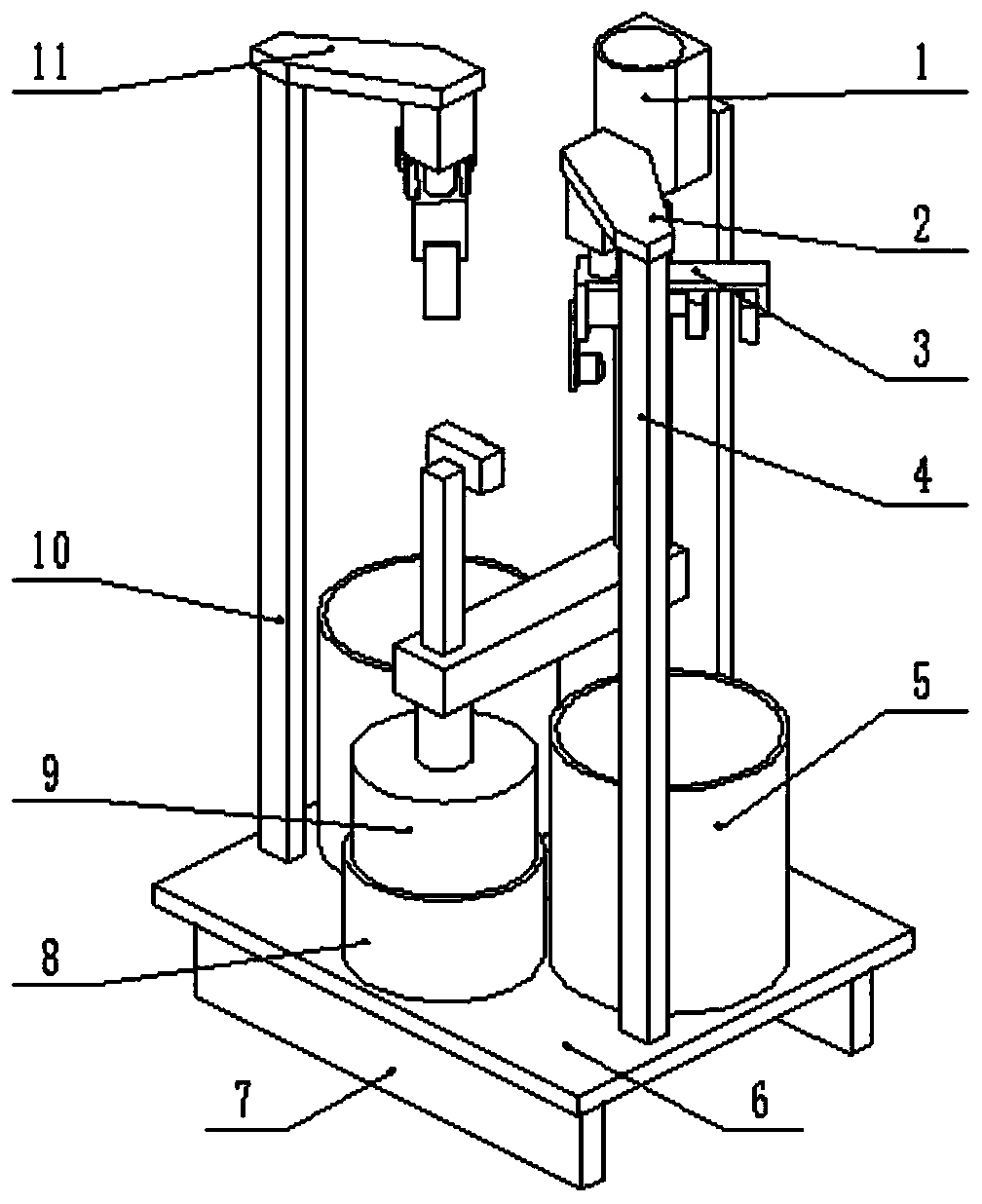

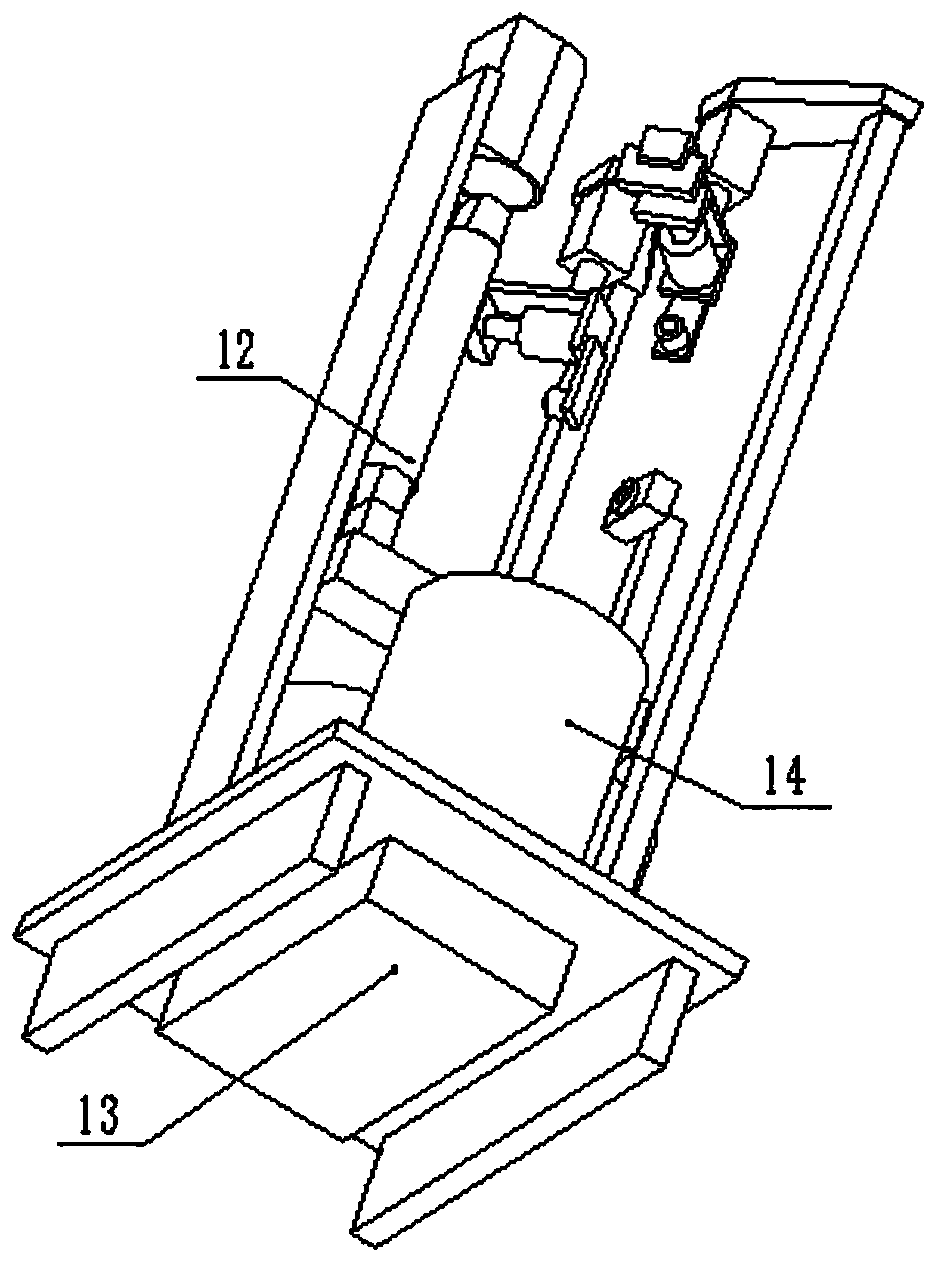

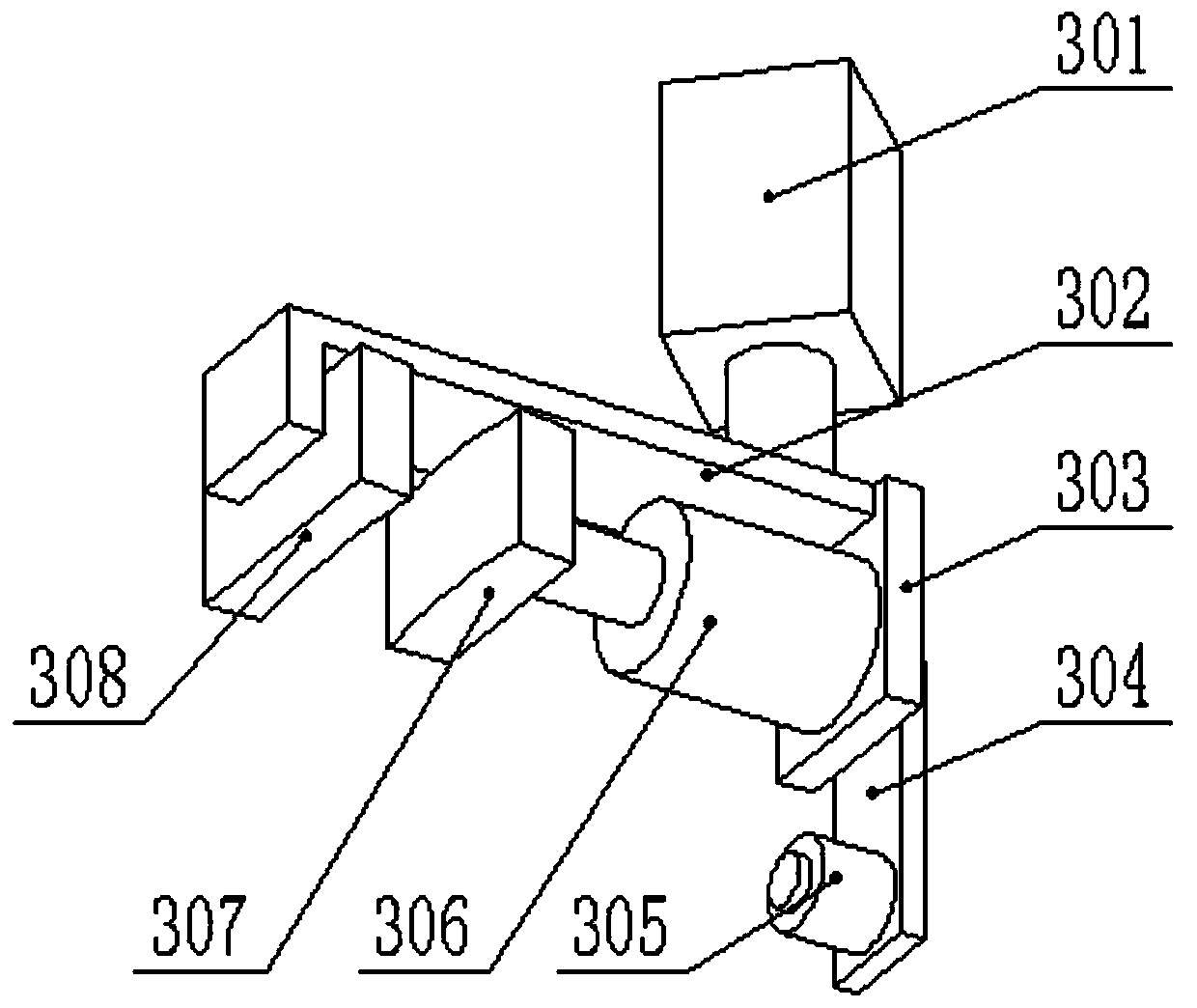

[0021] A waste steel pipe sorting device for construction engineering, including a guide hole 1, a first bracket 2, a clamping device 3, a second bracket 4, a first storage bucket 5, a base 6, legs 7, and a stepping motor base 8 , stepping motor 9, the third support 10, the fourth support 11, the transmission device 12, the controller 13 and the second storage barrel 14, the guide hole 1 is vertically fixed on the top of the base 6, which is located on the stepping motor base The rear of the top of the seat 8 is used to guide the steel pipe to accurately fall on the limit bracket 1201. The first bracket 2 is fixed on the top of the second bracket 4. There are two clamping devices 3, which are respectively fixed on the first bracket 2 and the top of the second bracket 4. Below the fourth bracket 11, it is used to clamp the top of the limit bracket 1201, separate the limit bracket 1201 from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com