Compound nutrient enhancer embedded with choline hydrogen tartrate and preparation method thereof

A technology of choline bitartrate and nutritional fortifier, which is applied to non-active ingredients in medical preparations, pharmaceutical formulas, digestive systems, etc. Good fluidity, mild conditions, the effect of avoiding vitamin reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

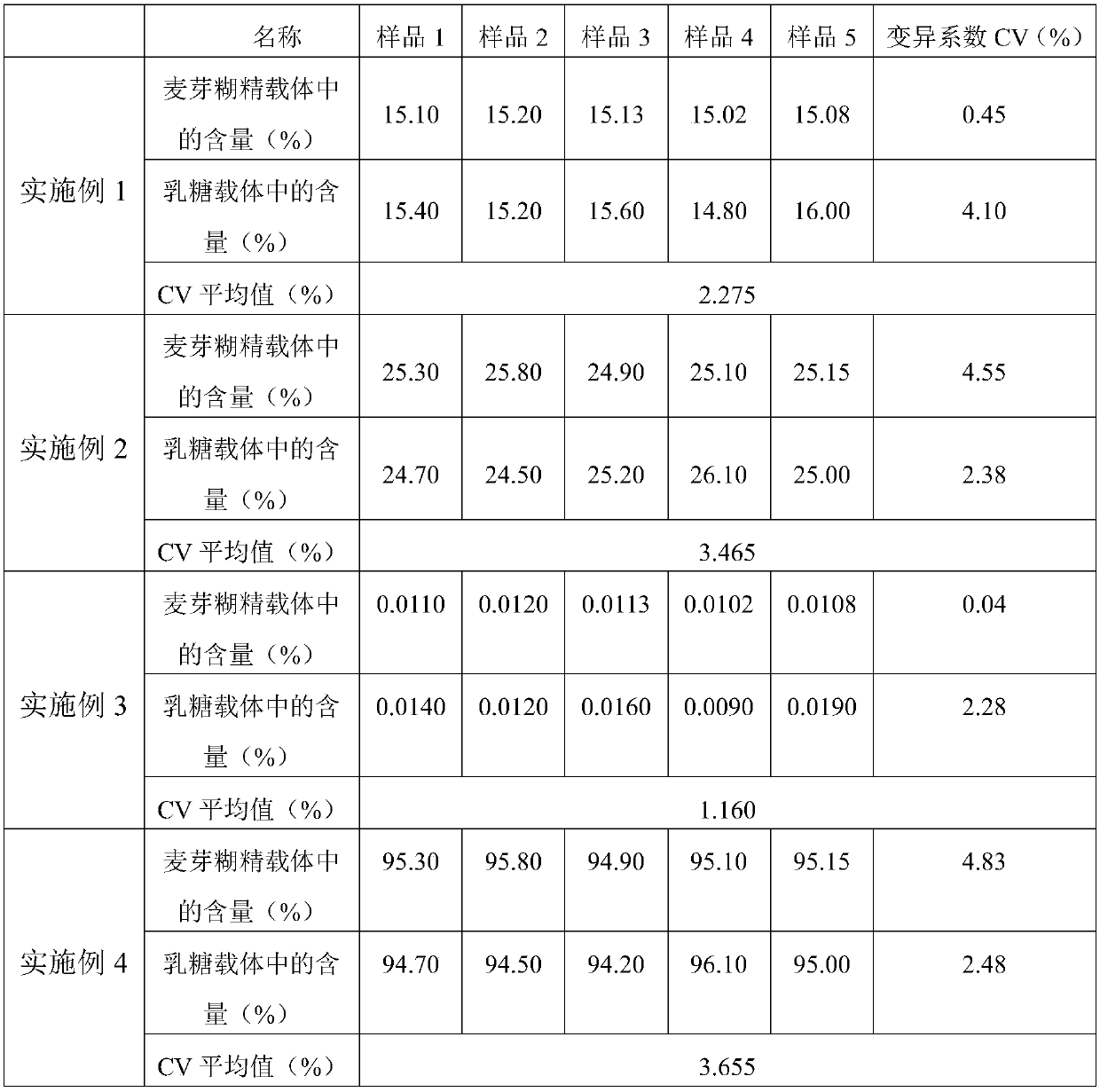

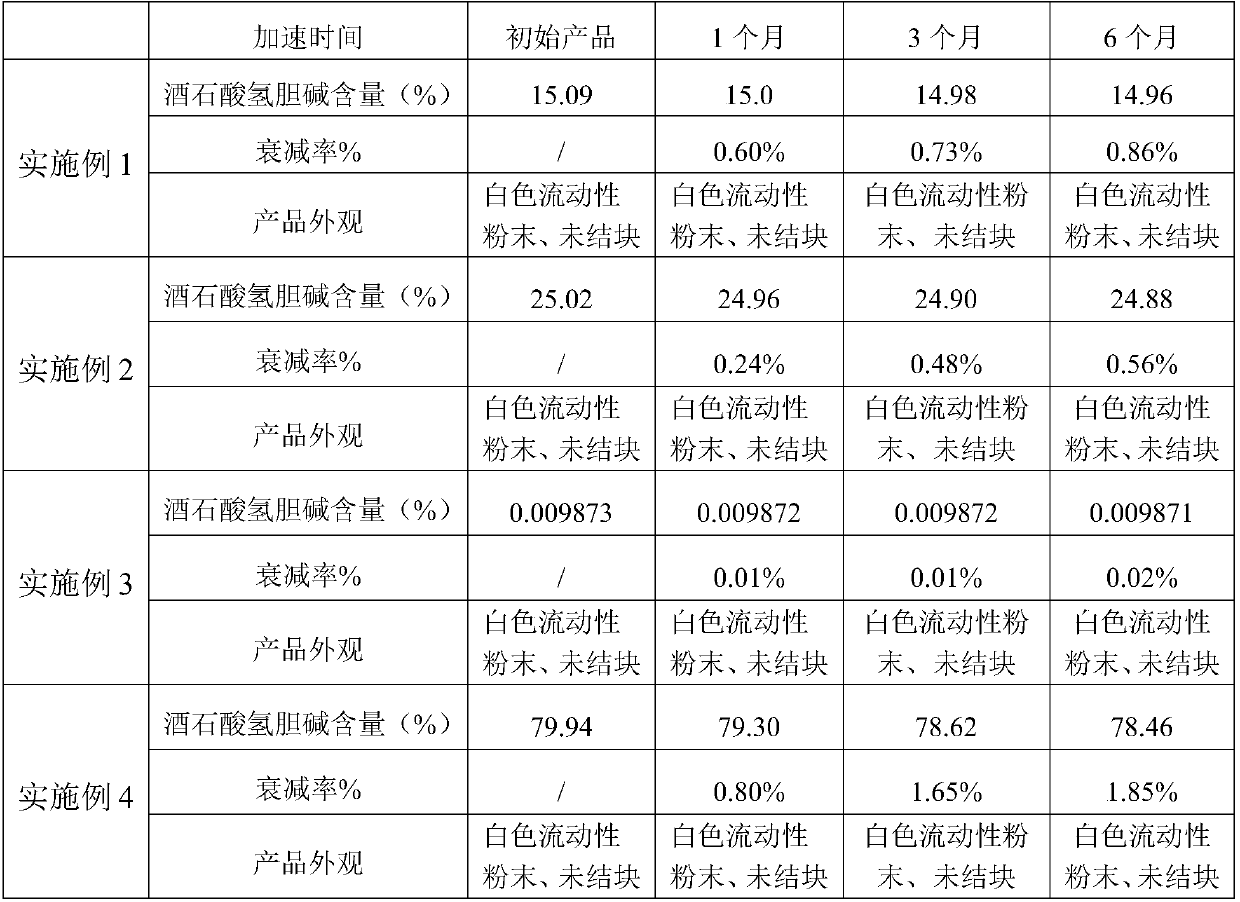

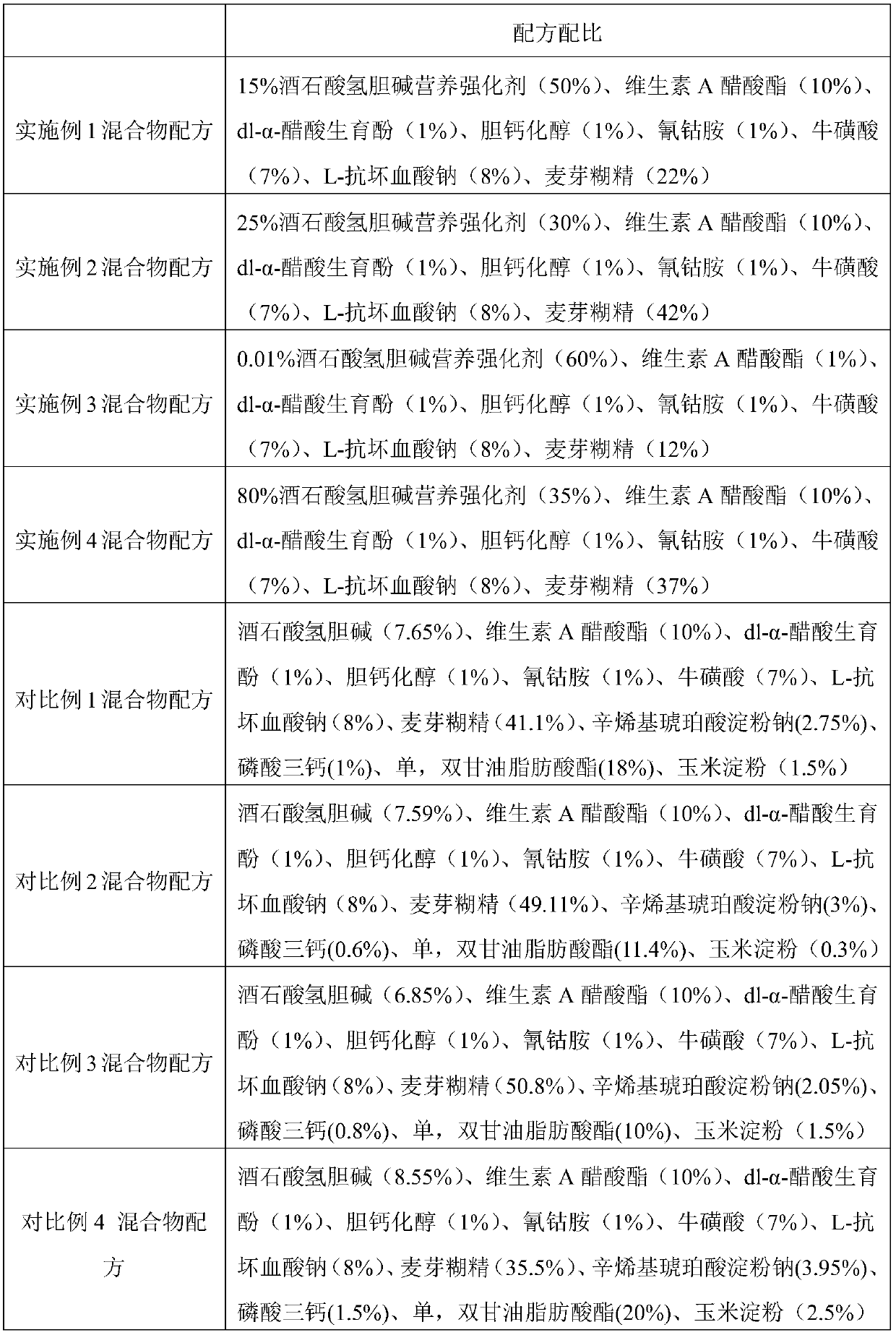

Examples

Embodiment 1

[0024] The preparation of the compound nutritional fortifier embedding choline bitartrate with a design content of 15%:

[0025] S1: Add 45.75kg of water into the dissolving pot, heat the water temperature to 55°C, slowly add 15.3kg of choline bitartrate and 3kg of corn starch into the dissolving pot, mix at a speed of 40r / min for 10min, and use it as solution A for later use;

[0026] S2: Add 199.25kg of water into another dissolving pot, heat the water temperature to 55°C, slowly add 5kg of sodium starch octenyl succinate and 5kg of mono- and diglyceride fatty acid esters into the dissolving pot at 40r / min Mix for 10 minutes at a rotating speed of 10 min, and use it as solution B;

[0027] S3: Shut down and introduce solution A into solution B, start the machine and continue mixing at a speed of 40r / min for 10min, and use it as solution C;

[0028] S4: The solution C was emulsified and stirred at room temperature with a high-shear dispersing emulsifier, and emulsified at a ...

Embodiment 2

[0033] The preparation of the compound nutritional fortifier embedding choline bitartrate with a design content of 25%:

[0034] S1: Add 65.75 kg of water into the dissolving pot, heat the water temperature to 55°C, slowly add 25.3 kg of choline bitartrate and 1 kg of corn starch into the dissolving pot, mix at a speed of 40 r / min for 10 min, and use it as solution A for later use;

[0035] S2: Add 179.25kg of water into another dissolving pot, heat the water temperature to 55°C, slowly add 5kg of sodium starch octenyl succinate and 5kg of mono- and diglyceride fatty acid esters into the dissolving pot at 40r / min Mix for 10 minutes at a rotating speed of 10 min, and use it as solution B;

[0036] S3: Shut down and introduce solution A into solution B, start the machine and continue mixing at a speed of 40r / min for 10min, and use it as solution C;

[0037] S4: The solution C was emulsified and stirred at room temperature with a high-shear dispersing emulsifier, emulsified at a...

Embodiment 3

[0042] The preparation of the compound nutritional fortifier embedding choline bitartrate with a design content of 0.01%:

[0043] S1: Add 20.75kg of water into the dissolving pot, heat the water temperature to 60°C, slowly add 0.01kg of choline bitartrate and 2kg of corn starch into the dissolving pot, mix at a speed of 20r / min for 20min, and use it as solution A for later use;

[0044] S2: Add 224.25kg of water into another dissolving pot, heat the water temperature to 60°C, slowly add 5kg of sodium starch octenyl succinate and 5kg of mono- and diglyceride fatty acid esters into the dissolving pot at 20r / min Mix at a rotating speed of 20 minutes, and use it as solution B;

[0045] S3: Shut down and introduce solution A into solution B, start the machine and continue mixing at a speed of 20r / min for 20min, and use it as solution C;

[0046] S4: The solution C was emulsified and stirred at room temperature with a high-shear dispersing emulsifier, and emulsified at a speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com