Longitudinal arm type independent suspension

A technology of independent suspension and trailing arm, applied in the direction of suspension, cantilever installed on pivot, interconnection system, etc., can solve the problems of low reliability, increased cost and weight, large layout space, etc., and achieve good isolation Effects of vibration and noise reduction, weight and cost reduction, and enhanced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0065] In addition, the "first" and "second" mentioned in the embodiments of the present invention are only for description purposes, and do not express or imply relative importance.

[0066] The present invention will be described in detail below with reference to the accompanying drawings and examples.

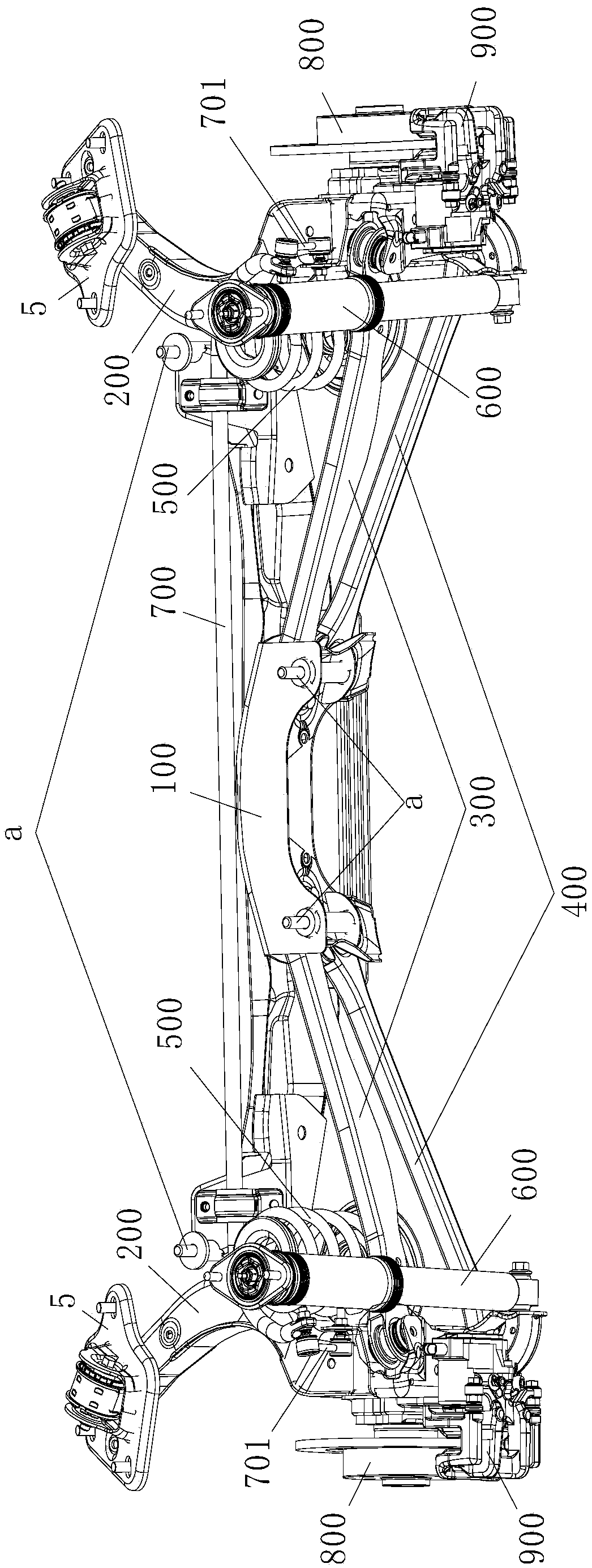

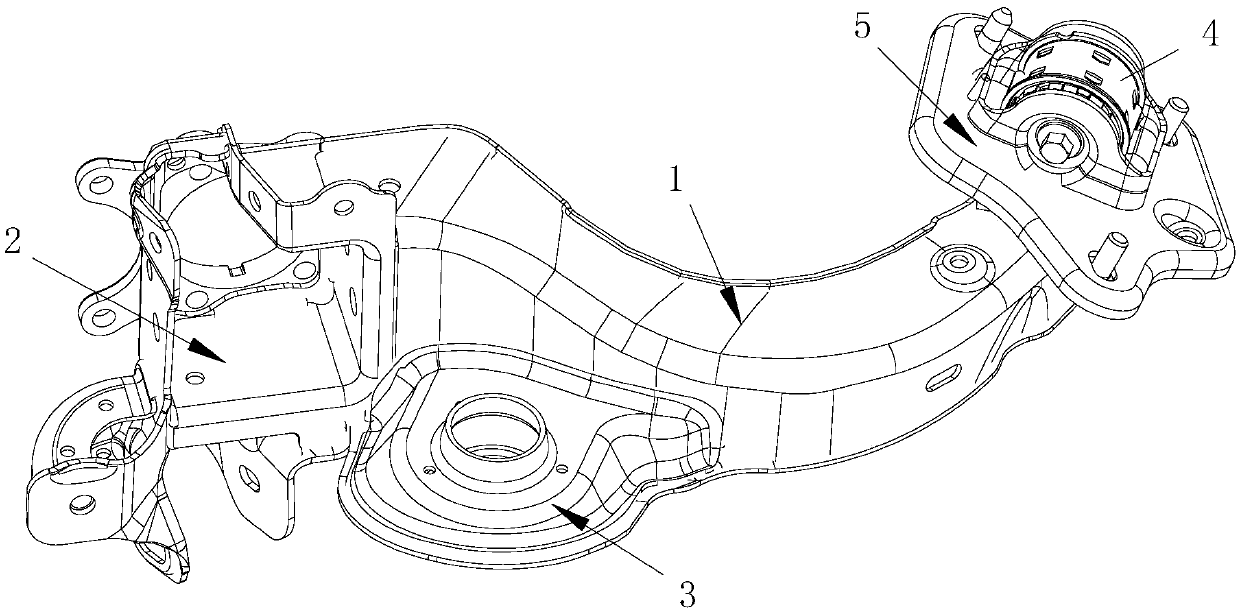

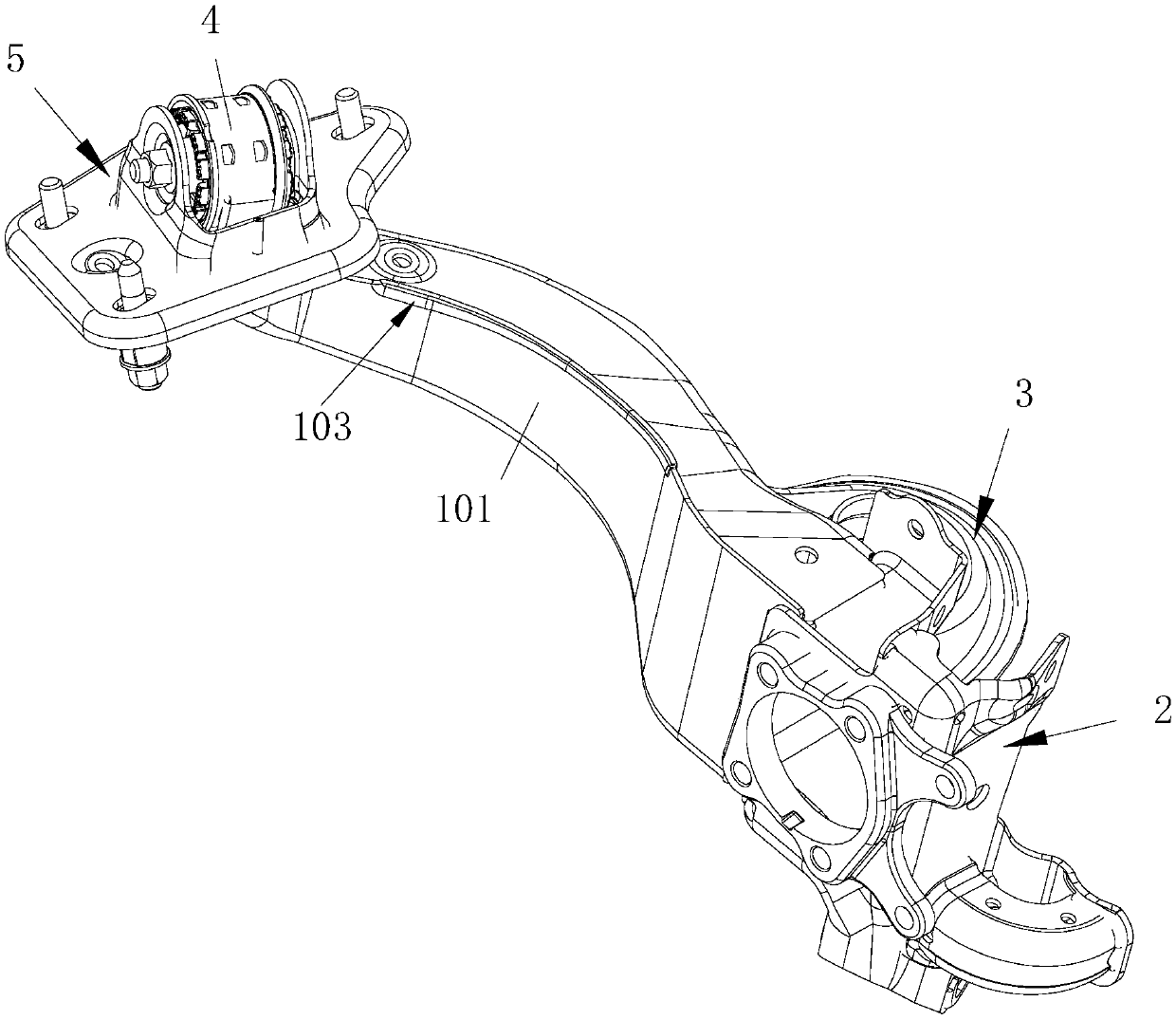

[0067] This embodiment relates to a trailing arm type independent suspension, such as figure 1 As shown in , it includes a subframe 100 as a whole, and two trailing arm assemblies 200 respectively arranged on both sides of the subframe 100, and the trailing arm assembly 200 has a trailing arm main body, and two trailing arm assemblies on the two sides of the trailing arm main body The hub support unit and the vehicle body connection unit respectively connected at the ends, and the spring support fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com