Evaporator, and control method for vacuum degree, evaporation kettle liquid level and water tank water level detection

A control method and technology of evaporating kettle, which are applied in water treatment parameter control, chemical instruments and methods, control/manipulation systems, etc., to achieve the effects of high energy utilization efficiency, high vacuum degree, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

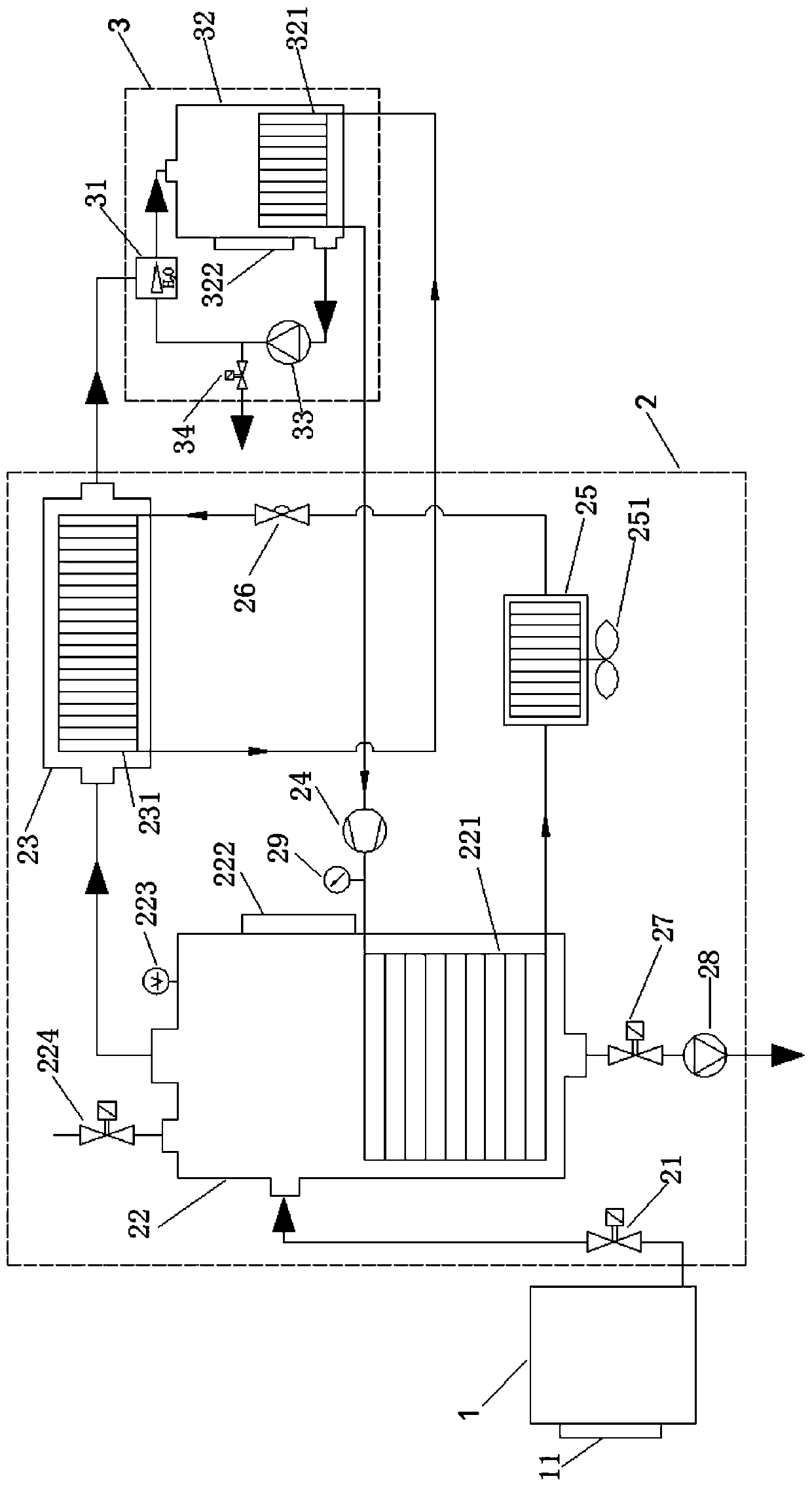

[0067] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0068] see figure 1 As shown, the control method of the evaporator includes the following steps:

[0069] ⑴The system is powered on and started;

[0070] (2) The first liquid level sensor detects the liquid level of the waste liquid tank;

[0071] (3) Detect whether the liquid level is low, if so, the first liquid level sensor sends a signal to the PLC, and the PLC controls to close the circulating water pump and open the vent valve, and return to step (2);

[0072] ⑷If not, the PLC controls to start the circulating water pump and open the liquid inlet valve. The circulating water pump runs to continuously pump out the air in the evaporator, making the evaporator become negative pressure;

[0073] (4.1) The third liquid level sensor detects the water level in the circulating water tank;

[0074] (4.2) Determine whether the water level is higher than the set hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com