Naphtha-containing raw material conversion method

A technology for naphtha and raw materials, applied in the field of catalysis, can solve problems such as small adjustable range, and achieve the effect of increasing the adjusting range and improving the ability to resist market fluctuation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

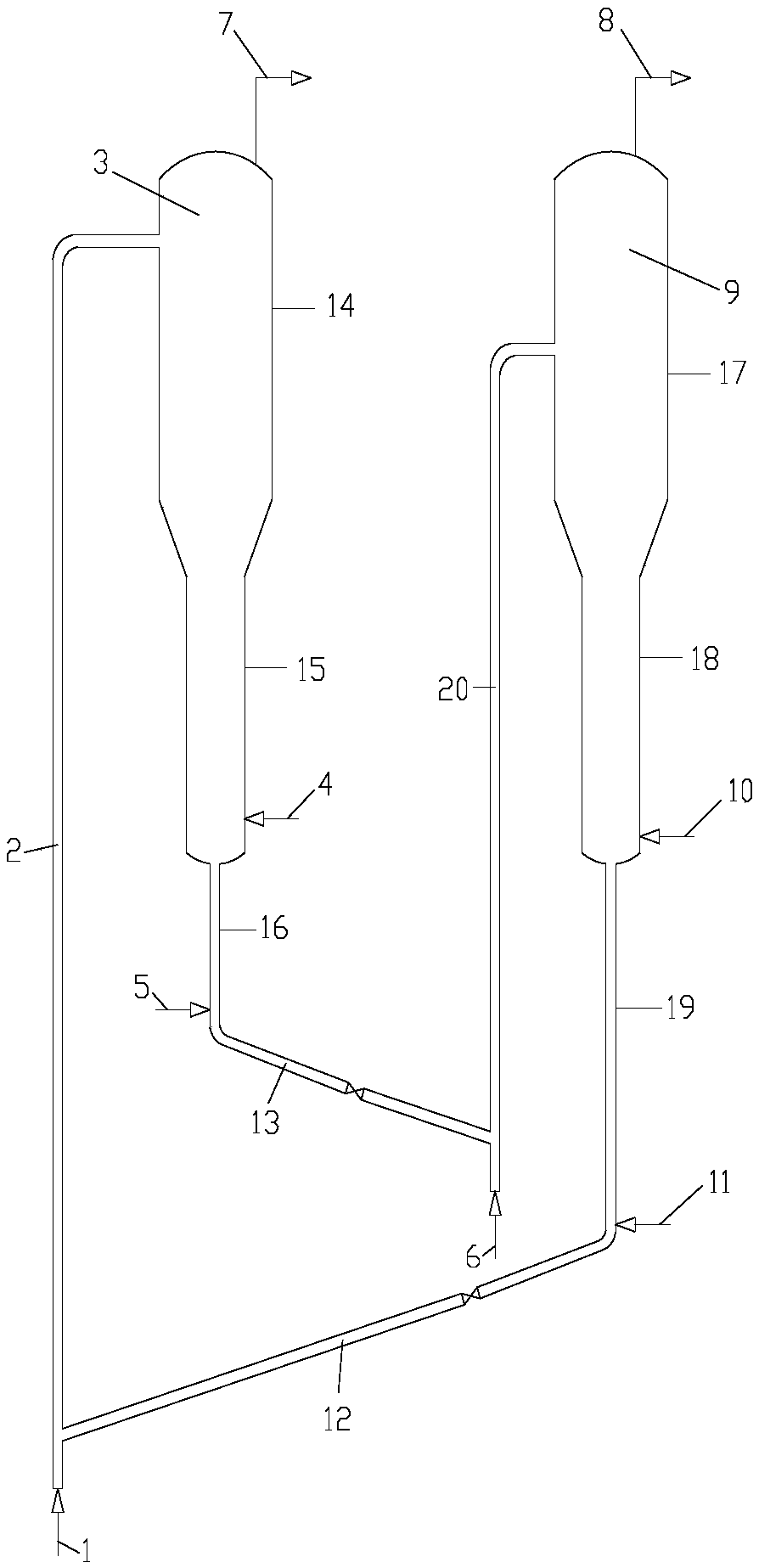

[0059] Such as figure 1 In the device shown, the catalyst is a microsphere catalyst containing naphtha catalytic cracking activity, the weight content of molecular sieve in the catalyst is 30%, and the particle size range is 50-150 microns. Raw materials including naphtha enter the riser reactor to contact with the catalyst, the generated product and catalyst flow enter the expansion section of the fluidized bed reactor for separation, the product enters the product gas outlet pipeline, and the catalyst enters the reaction section of the fluidized bed reactor, including the Raw materials of naphtha or / and methanol enter the reaction section of the fluidized bed reactor through the feed port of the fluidized bed reactor to react with the catalyst, and the generated product enters the product gas outlet pipeline, and the catalyst descends into the stripping section of the fluidized bed reactor. After stripping, it enters the regenerator through the inclined pipe to be produced a...

Embodiment 2

[0063] According to the conditions and steps described in Example 1, the catalyst is a microsphere containing naphtha catalytic cracking activity, the weight content of molecular sieve in the catalyst is 30%, and the particle size range is 50-150 microns. The carbon content of the regenerated catalyst is lower than 0.5%. Riser reactor conditions: reaction temperature is 680°C, reaction pressure is 0.01MPa by gauge pressure, gas phase linear velocity is 3m / s; fluidized bed reactor conditions: reaction temperature is 670°C, reaction pressure is 0.01MPa by gauge pressure 0.01MPa, the gas phase velocity is 1m / s, and the mass ratio of naphtha and methanol is 10. The mass ratio of the feed to the riser reactor and the fluidized bed reactor was 9:1. Keep the catalyst circulation stable, and the mass space velocity of the fluidized bed reactor is 0.5h -1 . The product gas is analyzed by online chromatography, and the mass yield of olefins is 45%, the mass yield of BTX is 18%, and t...

Embodiment 3

[0065] According to the conditions and steps described in Example 1, the catalyst is a microsphere containing naphtha catalytic cracking activity, the weight content of molecular sieve in the catalyst is 30%, and the particle size range is 50-150 microns. The carbon content of the regenerated catalyst is lower than 0.5%. Riser reactor conditions: reaction temperature is 680°C, reaction pressure is 0.01MPa by gauge pressure, gas phase linear velocity is 3m / s; fluidized bed reactor conditions: reaction temperature is 670°C, reaction pressure is 0.01MPa by gauge pressure 0.01MPa, the gas phase velocity is 1m / s, and the mass ratio of naphtha and methanol is 0.5. The mass ratio of the feed amount of the riser reactor and the fluidized bed reactor is 1:9. Keep the catalyst circulation stable, and the mass space velocity of the fluidized bed reactor is 1.5h -1 . The product gas is analyzed by online chromatography, and the mass yield of olefins is 72%, the mass yield of BTX is 16%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com