Continuous biomass depolymerization method

A biomass and depolymerization technology, which is applied in the field of biomass chemical industry technical equipment and energy, can solve the problems of affecting the depolymerization effect, discontinuous feeding, and difficult process repetition, so as to improve the depolymerization effect and realize continuous Operation, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

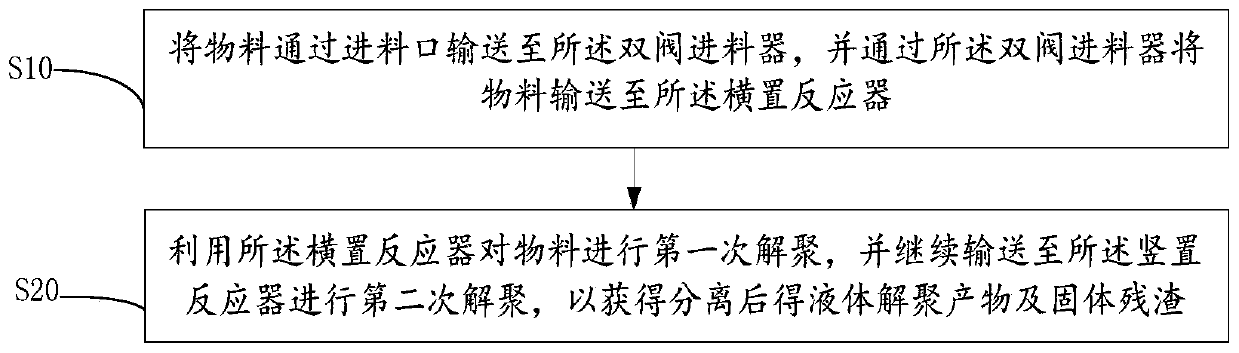

[0030] The embodiment of the present invention provides a kind of continuous depolymerization method of biomass, referring to figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the continuous depolymerization method of biomass in the present invention.

[0031] The continuous depolymerization process of biomass includes:

[0032] Step S10, transporting the material to the double-valve feeder through the feed port, and transporting the material to the horizontal reactor through the double-valve feeder;

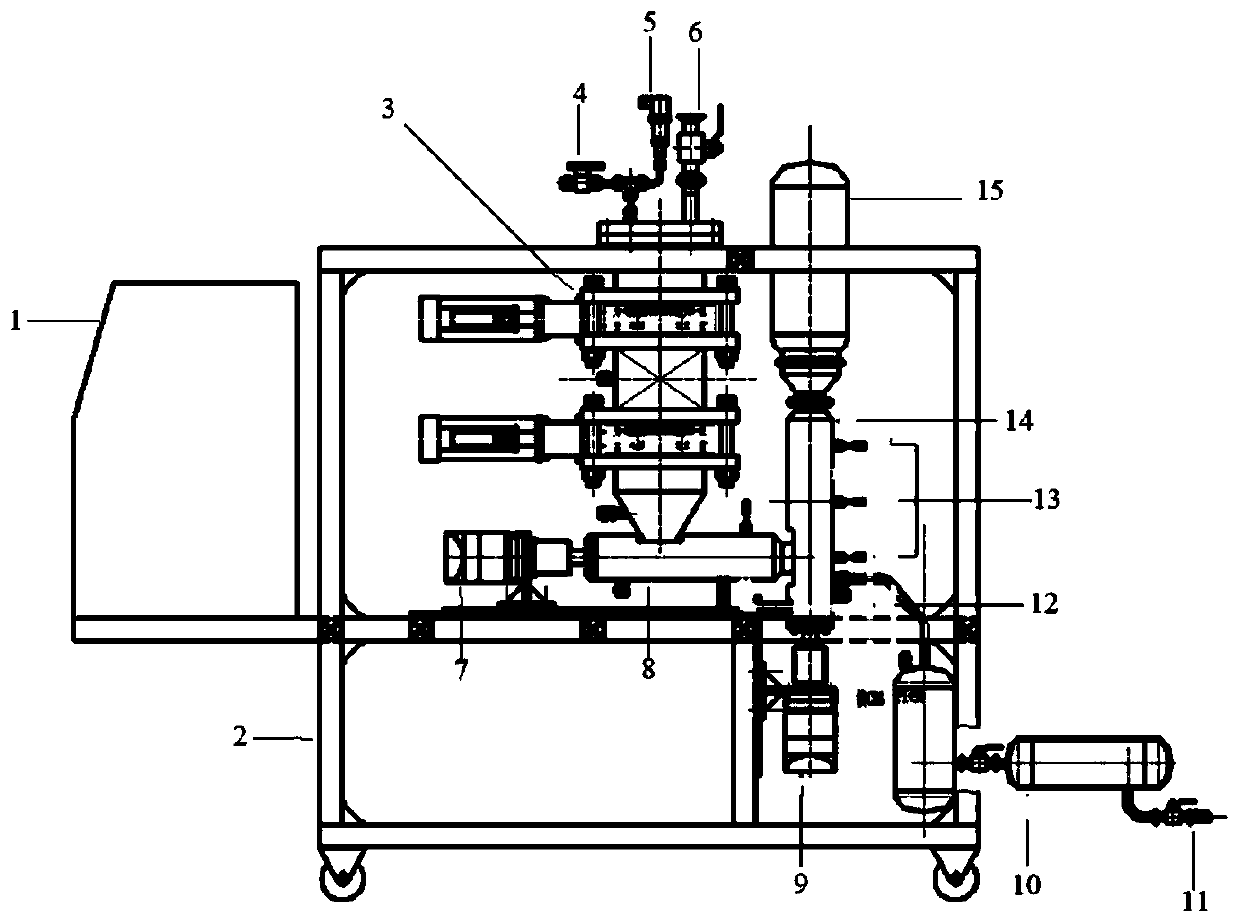

[0033] In this step, refer to figure 2 , figure 2 It is a continuous depolymerization device for biomass. As shown in the figure, the continuous depolymerization device includes a double-valve feeder, a horizontal reactor and a vertical reactor. The upper end of the horizontal reactor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com