Anti-condensation flame-retardant self-leveling foaming plugging material as well as preparation method and application thereof

A plugging material and foam stabilizer technology, applied in the field of materials, can solve the problems of poor sealing effect, short service life, unstable performance of plugging materials, etc., and achieve good heat preservation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

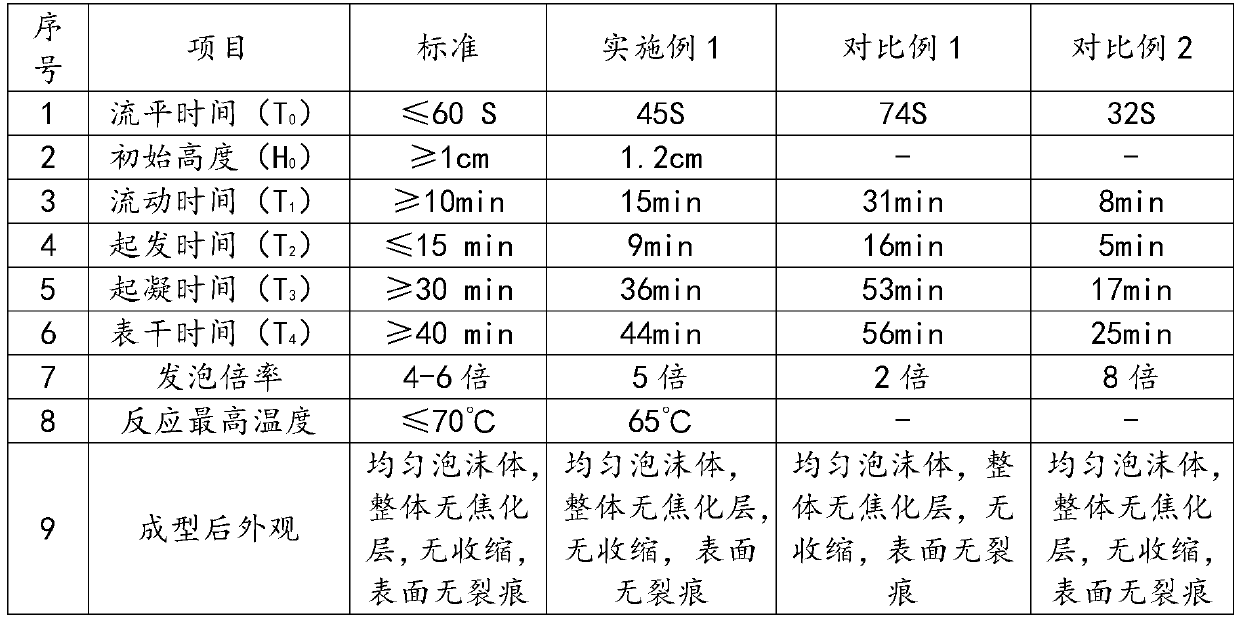

Examples

Embodiment 1

[0027] A plugging material, which is composed of material A, material B and material C; wherein material A contains 39.48wt% of polypropylene glycol, 2.1wt% of foam stabilizer, and 0.42wt% of catalyst; material B contains 42wt% of isocyanate; material C contains Expanded graphite powder 16w%.

[0028] Foam stabilizer is silicone oil L580. The isocyanate is toluene diisocyanate. The catalyst is N,N-dimethylcyclohexylamine.

[0029] The preparation method of the plugging material comprises the following steps:

[0030] S1. During the production of material A, the temperature is controlled at 10-40°C, and the catalyst: foam stabilizer: polypropylene glycol is mixed evenly in a weight ratio of 1:5:94; see figure 1 with figure 2 as shown,

[0031] S2. When material B and material C are produced, they are sealed and subpackaged according to the formula ratio in a dry environment, and they are individually packaged. see figure 1 with figure 2 shown.

[0032] During use, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com